BKNET-0102 Welded Pipe Eddy Current Flaw Detector

Non destructive weld testing equipment is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. At the same time, we need to be clear that the welded pipe is, in general, the steel pipe that we usually say, which is a welded steel pipe.

Eddy current weld testing is a non-destructive testing technique for detecting component defects by using the principle that the eddy current induced by the AC electromagnetic coil on the surface of the metal member encounters a defect. The oscillating current is generated in the conductive member by the excitation coil by the principle of electromagnetic induction, and the amount of change in the eddy current is measured by the detecting coil, thereby obtaining information on the component defect.

Eddy current testing is a non-destructive testing technique in which an alternating current electromagnetic coil induces eddy currents on the surface of a metal member. It is suitable for the detection of defects in conductive materials, including ferromagnetic and non-ferromagnetic metal materials.

BKNET-01�2 NDT weld testing equipment is used for on-line and off-line inspection of welded pipes. It has high sensitively to axial defects such as unwelded welding, dark spots and open cracks. In the production process, products are caused by welder failure. Slow and long-term injuries can be reliably detected.

BKNET-0102 Welded Pipe Eddy Current Flaw Detector Features:

1) High precision end and end-to-tail signal removal

2) High precision real-time, delayed alarm output

3) Fast digital/analog electronic balance

4) Memory track delay blanking function

5) Non-equal amplitude phase/amplitude alarm domain

6) Remote automatic help system

7) Synchronous alarm output for internal and external clock control

We are one of the leading ndt equipment manufacturers, RFQ today!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Eddy Current Testing Equipment | ECT Eddy current testing used by eddy current test setis a non-contact testing method, which mainly uses the electromagnetic field and electromagne... | |

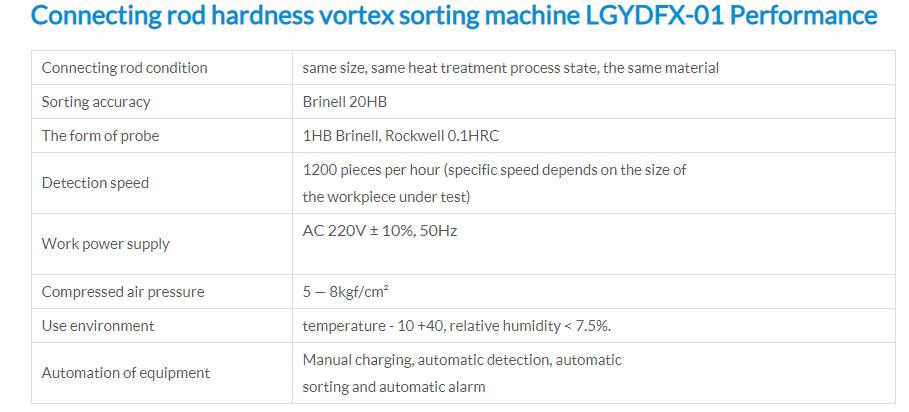

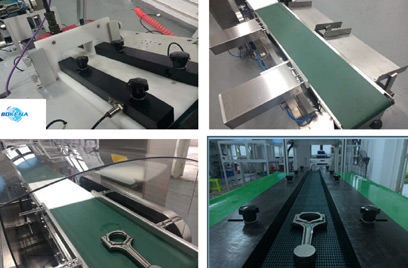

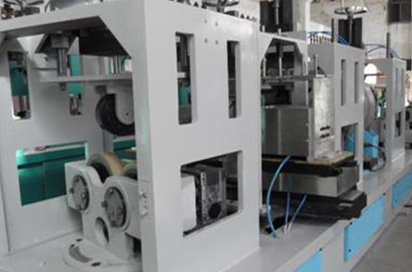

| Connecting rod hardness vortex sorting machine LGYDFX-01 | The connecting rod hardness eddy current testing machine has a calibration device, input compensation parameters, automatic/manual temperature comp... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| Eddy Current Testing Equipment | Are you looking for a perfect eddy current testing machine manufacturer? BOKENAis one of the most professional eddy current test equipment supplier... | |

| Portable Magnetic Flux Leakage Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... |

Похожие товары

| Electric Motorcycle High Energy Lithium Battery | Продавец: Taizhou CGONEN New Energy Co., Ltd. | Our 60V26Ah/ 60V29Ah/ 60V32Ah NMC high-speed electric motorcycle high-energy lithium batteries re... | |

| Тестер экрана iPhone Android серии JCID V15 | Продавец: С. так потрясена, что Technology Co.,Ltd. | ОписаниеТестер экрана JCID V15/V15PM поддерживает тестирование всех функций экрана iPhone и экран... | |

| Self Leveling Laser Level | Продавец: Holo Precision Instrument Co.,ltd. | When choosing a self-leveling laser level, several features should be considered : Accuracy L... | |

| Nivel De Laser | Продавец: Holo Precision Instrument Co.,ltd. | A great nivel de laser boasts essential features like high accuracy (measured in millimeter... | |

| Floor Laser Level | Продавец: Holo Precision Instrument Co.,ltd. | In the realm of precision tools, a ceiling laser level stands out as an indispensable asset for... |