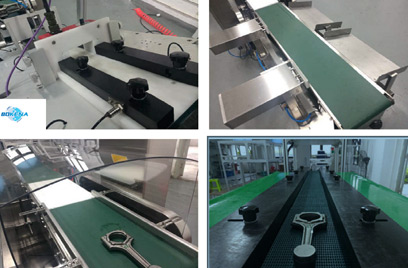

BKNET-0102 Welded Pipe Eddy Current Flaw Detector

Non destructive weld testing equipment is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. At the same time, we need to be clear that the welded pipe is, in general, the steel pipe that we usually say, which is a welded steel pipe.

Eddy current weld testing is a non-destructive testing technique for detecting component defects by using the principle that the eddy current induced by the AC electromagnetic coil on the surface of the metal member encounters a defect. The oscillating current is generated in the conductive member by the excitation coil by the principle of electromagnetic induction, and the amount of change in the eddy current is measured by the detecting coil, thereby obtaining information on the component defect.

Eddy current testing is a non-destructive testing technique in which an alternating current electromagnetic coil induces eddy currents on the surface of a metal member. It is suitable for the detection of defects in conductive materials, including ferromagnetic and non-ferromagnetic metal materials.

BKNET-01�2 NDT weld testing equipment is used for on-line and off-line inspection of welded pipes. It has high sensitively to axial defects such as unwelded welding, dark spots and open cracks. In the production process, products are caused by welder failure. Slow and long-term injuries can be reliably detected.

BKNET-0102 Welded Pipe Eddy Current Flaw Detector Features:

1) High precision end and end-to-tail signal removal

2) High precision real-time, delayed alarm output

3) Fast digital/analog electronic balance

4) Memory track delay blanking function

5) Non-equal amplitude phase/amplitude alarm domain

6) Remote automatic help system

7) Synchronous alarm output for internal and external clock control

We are one of the leading ndt equipment manufacturers, RFQ today!

在线联系供应商

Other supplier products

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... | |

| Magnetic Flux Leakage Testing Equipment | Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage is a magnetic method of nond... | |

| Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 | During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion of all d... | |

| BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator | Eddy Current Brake for Sale Stimulating the coil makes a magnetic induction to the tested material. The induced electromotive force received by th... | |

| Eddy Current Testing Equipment | ECT Eddy current testingis a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals t... |

Same products

| Electric Motorcycle High Energy Lithium Battery | 卖方: Taizhou CGONEN New Energy Co., Ltd. | Our 60V26Ah/ 60V29Ah/ 60V32Ah NMC high-speed electric motorcycle high-energy lithium batteries re... | |

| JCID V15系列 iPhone Android 屏幕测试仪 | 卖方: 深圳维客修有限公司 | 描述JCID V15/V15PM屏幕测试仪支持测试iPhone屏幕和Android Phone屏幕的全部功能,如iPhone LCD屏幕触摸功能测试、单色测试、图片测试和灰度测试。全新JCID ... | |

| Self Leveling Laser Level | 卖方: Holo Precision Instrument Co.,ltd. | When choosing a self-leveling laser level, several features should be considered : Accuracy L... | |

| Nivel De Laser | 卖方: Holo Precision Instrument Co.,ltd. | A great nivel de laser boasts essential features like high accuracy (measured in millimeter... | |

| Floor Laser Level | 卖方: Holo Precision Instrument Co.,ltd. | In the realm of precision tools, a ceiling laser level stands out as an indispensable asset for... |