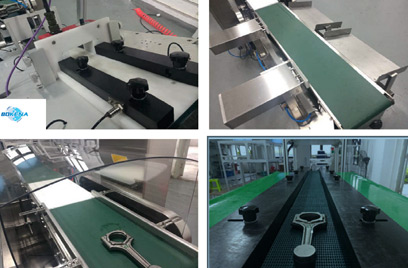

BKNET-0102 Welded Pipe Eddy Current Flaw Detector

Non destructive weld testing equipment is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. At the same time, we need to be clear that the welded pipe is, in general, the steel pipe that we usually say, which is a welded steel pipe.

Eddy current weld testing is a non-destructive testing technique for detecting component defects by using the principle that the eddy current induced by the AC electromagnetic coil on the surface of the metal member encounters a defect. The oscillating current is generated in the conductive member by the excitation coil by the principle of electromagnetic induction, and the amount of change in the eddy current is measured by the detecting coil, thereby obtaining information on the component defect.

Eddy current testing is a non-destructive testing technique in which an alternating current electromagnetic coil induces eddy currents on the surface of a metal member. It is suitable for the detection of defects in conductive materials, including ferromagnetic and non-ferromagnetic metal materials.

BKNET-01�2 NDT weld testing equipment is used for on-line and off-line inspection of welded pipes. It has high sensitively to axial defects such as unwelded welding, dark spots and open cracks. In the production process, products are caused by welder failure. Slow and long-term injuries can be reliably detected.

BKNET-0102 Welded Pipe Eddy Current Flaw Detector Features:

1) High precision end and end-to-tail signal removal

2) High precision real-time, delayed alarm output

3) Fast digital/analog electronic balance

4) Memory track delay blanking function

5) Non-equal amplitude phase/amplitude alarm domain

6) Remote automatic help system

7) Synchronous alarm output for internal and external clock control

We are one of the leading ndt equipment manufacturers, RFQ today!

Send product request

Other supplier products

| BKNET-101 Automatic Eddy Current Testing | The eddy current testing(BKNET-101) is a fully automated eddy current inspection system that uses large-scale imported integrated circuits combined... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| Magnetic Flux Leakage Testing Equipment | Electromagnetic detection is a very important non-destructive testing method and is widely used. Mag flux testingis a magnetic method of nondestruc... | |

| Rod Tube Rotary Eddy Current Flaw Detector ET 15/40/65/90 | Rod Tube Rotary Eddy Current Flaw Detector ET 15406590 Brief Rod Tube Rotary Eddy Current Flaw Detector ET 15406590 Performance Testing Standa... | |

| Bolt Eddy Current Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... |

Same products

| Plastic Smoke Density Tester F313 | Seller: Standard International Group (HK) Limited | The F313 Plastic Smoke Density Tester is a precision instrument designed to measure the specific ... | |

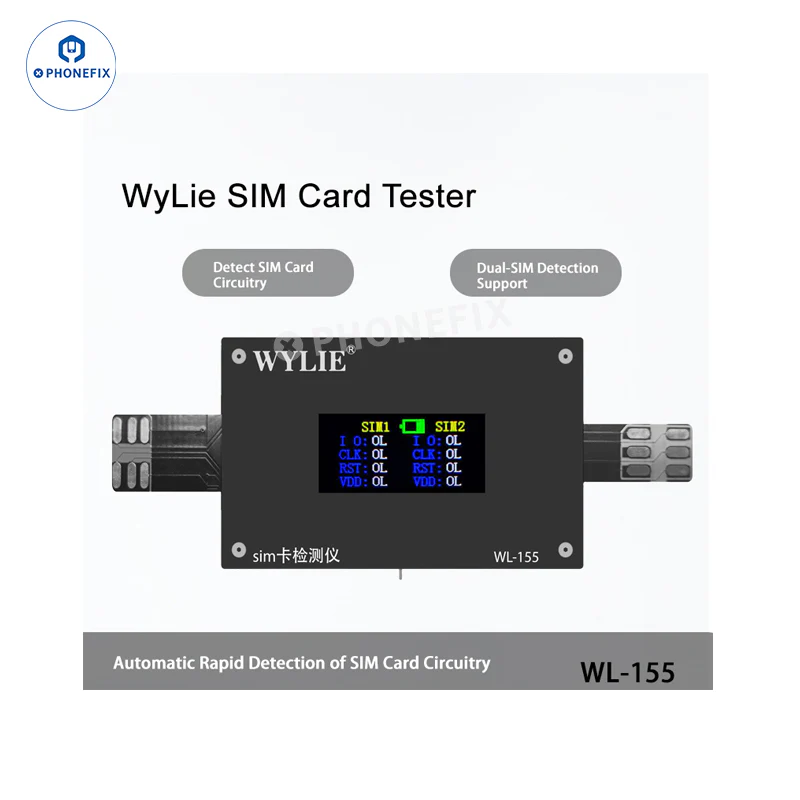

| WYLIE WL-155 SIM Card Tester for iPhone 14-17 Pro Max & Android | Seller: China PHONEFIX Technology Co., Ltd | WYLIE WL-155 SIM Card Tester is used to detect SIM card circuits and supports dual-SIM detection ... | |

| HCV1500 High-precision Voltage Sensor | Seller: Shenzhen Hangzhi Precision Electronics Co., Ltd | HCV1500 high-precision voltage sensor is a voltage sensor that can measure DC, AC, pulse and vari... | |

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... |