fogging test equipment

Working Principle:

The main frame of theFogging Testerincludes a water sink fully filled with specified ethylene glycol, which can reach a high temperature. At the time of testing, leather specimens are put in the six standard glass containers filled with high temperature liquid, and the stainless steel containers are placed above each glass.

Relying on the constant water flow distribution, the temperature can maintain at 20℃ constantly, and it can be adjusted through the regulation device connected to the main frame. This controlled environment condition will generate a layer of “fog” on the surface of specimens. The operator can determine the fogging characteristics of materials based on gravimetric analysis method or refraction method.

Brief Introduction:

Thefogging test equipmentis designed to test the fogging phenomena of leather and fabric under specified environment conditions, suitable for the fogging property evaluation of volatile components of the interior trimming materials used in cars and aircrafts under high temperature, and the instrument can also be used to test the fogging property of car xenon lamps.

Standards

DIN 75201 Determination of the fogging characteristics of trim materials in the interior of automobiles

ISO 6452 Rubber or plastics coated fabrics-determination of fogging characteristics of trim materials

in the interior of automobiles

SAE J1756 Test procedure to determine the fogging characteristics of interior automotive materials

QB/T 2728 Leather-physical and mechanical test-determination of fogging characteristics.

BS EN 14288 Leather - Physical and mechanical tests - Determination of fogging characteristics

PV 3920 Determination of fog value (F) of non-metallic interior materials

PV 3015 Non-metallic materials for interior trim-determination of condensable constituents.

ES-X83231 Standard test method-For fogging of interior materials

NES M0161 Interior materials fog test method

D45 1727 TRIM MATERIALS AND PARTS FOR INTERIOR AND PASSENGER COMPARTMENT PARTS - FOGGING - CONDENSATION

GM 9305P Determination of fogging characteristics of automotive interior trim materials

TSM 0503G Fogging test method for non-metallic materials

Features:

CONSTRUCTIVE CHARACTERISTICS:

· Internal carrying plane, in structural treated steel, anti-acid painted.

·External protection in sheet steel of proper thickness, anti-acid treated and painted with epoxy resin.

·six work places 18/8 Inox steel test room.

·18/8 Inox steel lift able cooling system.

·Rapid clutch Agitation System.

· Armored resistances.

· Security thermostat.

· Cooling liquid and relief entry etching with rubber-carrier.

Send product request

Other supplier products

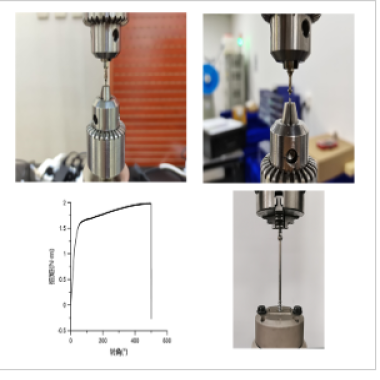

| Torque - to - Failure Tester for Metal Bone - connecting Screws | Standard YY/T 0662-2008(Chinese standard for orthopedic implant testing) ISO 5832-1(Metallic materials for surgical implants – Wrought stai... | |

| Fully Automatic Continuous Flow Reaction Calorimeter | Product Features: 1. Using the coefficient calibration method and flow - regulation calorimetry, it can quickly obtain the reaction heat release a... | |

| Shoelace eye wear testing machine | Main uses: The shoelace eye wear testing machine is mainly used to test the wear resistance of shoelace and shoe eye under repeated friction. The ... | |

| Minimum Ignition Temperature (MIT) – Dust Cloud Tester | Description Dust Cloud Minimum Ignition Temperature Tester is mainly used to assess the explosiveness of dust in the production and processing pla... | |

| Fire retardant coatings tester tunnel method | Product Introduction: The fire retardant coating flame propagation tester is suitable for testing the flame propagation characteristics of the fir... |

Same products

| Briefly describe the importance, core functionality and how to implement a hospital clock system solution | Seller: California Triangle | In the healthcare industry, precise time synchronization is critical. Every second can be a matte... | |

| Sand and Dust Test Chamber for Automotive Connectors | Seller: Standard International Group (HK) Limited | Operating Conditions: Ambient temperature: 5°C~+28°C (average temperature within 24 hour... | |

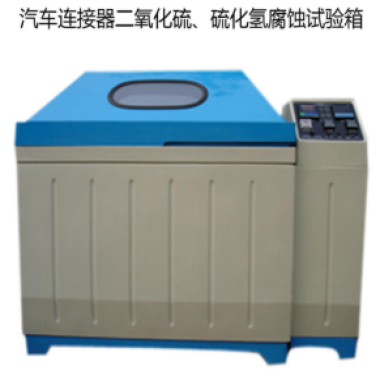

| Automotive Connector SO₂/H₂S Corrosion Test Chamber | Seller: Standard International Group (HK) Limited | Standards: GB/T 10587-89. GB/T 2423.9-93: Chinese national standards for sulfur dioxide corrosio... | |

| Automotive Connectors Salt Spray Tester | Seller: Standard International Group (HK) Limited | Applicable Standards: Neutral Salt Spray (NSS) Tests: GB/T2423.17. ISO 3768/3769/3770. ASTM B117... | |

| Air - tightness Testing Device for Automotive Connectors | Seller: Standard International Group (HK) Limited | Main Functions: 1. Provide stable positive and negative pressures for testing the air - tightnes... |