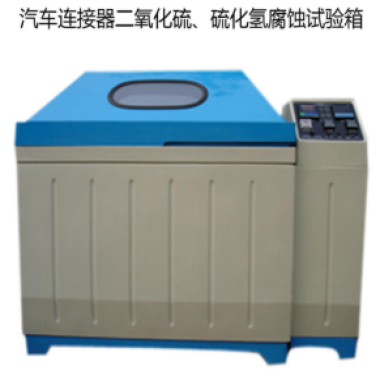

Automotive Connector SO₂/H₂S Corrosion Test Chamber

Standards:

GB/T 10587-89. GB/T 2423.9-93: Chinese national standards for sulfur dioxide corrosion testing.

GJB 150: China’s military-grade environmental testing specifications.

QC/T 417.1-2001: Automotive industry standard for electric connector corrosion resistance.

Equivalent International Standards: IEC 60068-2-43. DIN 50018. MIL-STD-810G, ASTM G85 (Annex A5).

Technical Parameters:

1. Temperature range: 10 - 55°C

2. Temperature fluctuation: ±0.5°C

3. Temperature uniformity: ±2°C

4. Sulfur dioxide gas concentration: 100ppb - 50000ppb (0.1ppm - 50ppm)

5. Hydrogen sulfide gas concentration: 10ppb - 5000ppb (0.01ppm - 5ppm)

6. Relative humidity: 75±3%

7. Tests with sulfur dioxide, hydrogen sulfide, and mixed gases of sulfur dioxide and hydrogen sulfide can be conducted.

Environmental Requirements:

1. Power supply: AC380V 3Φ 10KVA 0HZ

2. Allowable voltage range: ±5% of the rated value

3. Maximum load: 6KVA

4. The distance between the chamber and the wall should be greater than 600cm.

Structural Materials and Features:

1. The chamber is molded from epoxy fiberglass. Asbestos board is pasted inside the jacket. It is resistant to high temperature and corrosion, lightweight, and has high strength. Both the inner and outer walls of the chamber are smooth and easy to clean. 2. The chamber cover is made of epoxy fiberglass with a top cover temperature of 100 - 200°C to prevent condensed water in the chamber from dripping directly onto the test specimens.

3. Heater: The nickel - chromium alloy heating wire heats from the bottom, forming jacket heating to ensure good temperature uniformity inside the chamber.

4. Humidification method: Humidification by a steam generator.

5. Input methods for sulfur dioxide and hydrogen sulfide: Input from cylinders, and both input and discharge are quantitatively controlled by concentration sensors.

6. Exhaust gas treatment: Install treatment devices for sulfur dioxide and hydrogen sulfide gases. After multi - stage treatment with sodium bicarbonate, the exhaust gas meets the discharge standards (the purification device is external).

Control System:

1. Temperature control: Japanese Fuji temperature controller

2. Temperature input: PT100; Output: Driven by SSR

3. Display range: 0 - 100°C

4. Control range: RT + 5 - 55°C

5. Cycle used (measurement filtering): 2 - 3s

6. The main control components are products from joint - venture companies.

7. The temperature is controlled by a solid - state relay, with stable performance and no noise.

8. A fan is used for stirring and circulation inside the chamber. 9. Display and control of sulfur dioxide concentration

Send product request

Other supplier products

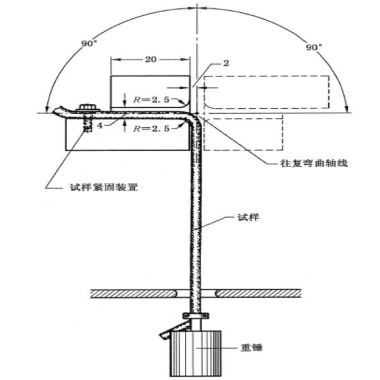

| (Changan) Automobile wire and wire bending testing machine | Standard: DIN 51211 and ISO 7801 Scope of application: Changan Automobile "JT automobile low-voltage wire technical conditions" standard Techni... | |

| Geosynthetics thickness tester-QINSUN | Scope of application: Used to determine the thickness of various geosynthetic materials under specified pressure and time. The sample is placed on... | |

| Shoe Abrasion Tester | Product Introduction: The whole shoe wear testing machine is used to test the wear resistance of soles and sole pieces. The principle is to press ... | |

| 45-degree dry cleaning tester | Product Introduction: The instrument is composed of a bottom plate, a control panel and a drum. The clothes to be washed and the dry cleaning agen... | |

| Dry Cleaning & Washing Cylinder | Introduction The dry cleaning and washing cylinder consists of a stainless steel rotary test chamber and a multi-speed drive with a digital timer.... |

Same products

| Briefly describe the importance, core functionality and how to implement a hospital clock system solution | Seller: California Triangle | In the healthcare industry, precise time synchronization is critical. Every second can be a matte... | |

| Sand and Dust Test Chamber for Automotive Connectors | Seller: Standard International Group (HK) Limited | Operating Conditions: Ambient temperature: 5°C~+28°C (average temperature within 24 hour... | |

| Automotive Connector SO₂/H₂S Corrosion Test Chamber | Seller: Standard International Group (HK) Limited | Standards: GB/T 10587-89. GB/T 2423.9-93: Chinese national standards for sulfur dioxide corrosio... | |

| Automotive Connectors Salt Spray Tester | Seller: Standard International Group (HK) Limited | Applicable Standards: Neutral Salt Spray (NSS) Tests: GB/T2423.17. ISO 3768/3769/3770. ASTM B117... | |

| Air - tightness Testing Device for Automotive Connectors | Seller: Standard International Group (HK) Limited | Main Functions: 1. Provide stable positive and negative pressures for testing the air - tightnes... |