Sand and Dust Test Chamber for Automotive Connectors

Operating Conditions:

Ambient temperature: 5°C~+28°C (average temperature within 24 hours ≤28°C); Ambient humidity: ≤85%

Technical Parameters:

1. Nominal spacing of the metal mesh is 50μm, and the nominal spacing between wires is 70μm

2. Airflow velocity: ≤2m/s (standard type) or ≥2m/s (specify when placing an order) 3. Continuous or periodic dust - blowing can be freely selected, or time can be set 4. Talcum powder dosage: 2kg - 4kg/㎡ 5. Dust for testing: Dry talcum powder, portland cement, soot, etc. 6. Vibration time: adjustable from 0 to 9999 minutes (M represents minutes) 7. Fan cycle time: 0 to 9999 minutes (M represents minutes) 8. Standard configuration: The sand and dust testing equipment is equipped with 2 specimen racks and 2kg of talcum powder 9. Power requirements: AC380(±10%)V/50HZ, three - phase five - wire

Product Applications:

This equipment is suitable for dust - proof and dust - resistance tests of various automotive components, including vehicle lamps, instruments, electrical dust - proof sleeves, steering systems, door locks, etc., to verify the sealing quality of products.

Structural Features:

1. Material of the chamber outer shell: High - quality carbon steel plate, with phosphating and electrostatic powder spraying on the surface, and hairline treatment for SUS304 stainless - steel strips; 2. Inner liner material: Imported SUS stainless - steel polished plate; 3. Chamber door: Tempered glass door, facilitating the observation of the tested samples inside the test chamber; 4. High - quality fixed PU casters are used at the bottom; 5. There is a dust - replacement device at the bottom of the test chamber

System Structure:

1. Control system: The sand and dust testing equipment is controlled by a programmable logic PLC controller to manage the time and sequence of the dust - blowing, vibration and vacuum systems

2. Actuating components: "Schneider" AC contactors, switches, buttons; "Fuji" intermediate relays; "Panasonic" dust - proof sockets

3. Dust pre - heating system: Stainless - steel mica heating jacket, with stable and safe heat; it has timer - controlled heating; Vacuum system: Equipped with a pressure gauge, air filter, pressure - regulating triple unit and connecting pipes (the vacuum pump is provided separately, please specify when placing an order)

4. Power socket for test specimens: Dust - proof socket, AC220V 16A

5. Circulating fan: Low - noise motor with a multi - blade centrifugal impeller

6. Protection system: With protection functions against electric leakage, short - circuit, over - temperature, motor overheating, over - current / power - off memory protection for the controller

Send product request

Other supplier products

| Plastic Pipe Hydrostatic Pressure Burst Tester | Standard ISO 1167: For thermoplastics pipe systems under constant internal pressure. ASTM D 1598: Standard test method for time-to-failure of pla... | |

| Paper Grammage Tester | ||

| Yarn Twist Tester | Application ScopeThe yarn twist tester is an instrument used to measure the twist of yarns and their related technical indicators.Applicable Standa... | |

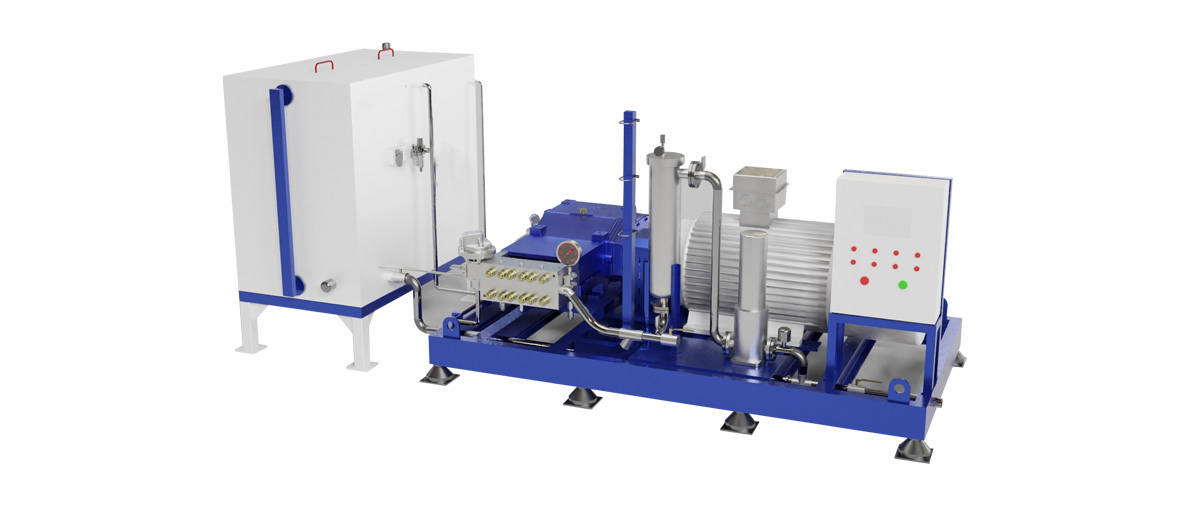

| 1600 bar Pump Units | For industrial pipeline dredging, tank reactor cleaning Concrete removal,truck tank cleaning, surface cleaning, industry process pumping. Features... | |

| Desktop Xenon lamp aging test chamber | TheXenon lamp aging test chamberis a photoaging tester for large-capacity textile testing. With additional sample light frame, temperature sensor a... |

Same products

| Briefly describe the importance, core functionality and how to implement a hospital clock system solution | Seller: California Triangle | In the healthcare industry, precise time synchronization is critical. Every second can be a matte... | |

| Sand and Dust Test Chamber for Automotive Connectors | Seller: Standard International Group (HK) Limited | Operating Conditions: Ambient temperature: 5°C~+28°C (average temperature within 24 hour... | |

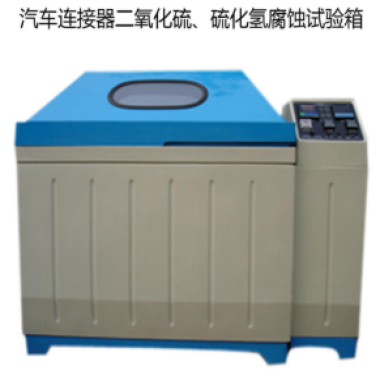

| Automotive Connector SO₂/H₂S Corrosion Test Chamber | Seller: Standard International Group (HK) Limited | Standards: GB/T 10587-89. GB/T 2423.9-93: Chinese national standards for sulfur dioxide corrosio... | |

| Automotive Connectors Salt Spray Tester | Seller: Standard International Group (HK) Limited | Applicable Standards: Neutral Salt Spray (NSS) Tests: GB/T2423.17. ISO 3768/3769/3770. ASTM B117... | |

| Air - tightness Testing Device for Automotive Connectors | Seller: Standard International Group (HK) Limited | Main Functions: 1. Provide stable positive and negative pressures for testing the air - tightnes... |