4-station Leather Rubbing Color Fastness Tester

Standards

- ISO 11640(Leather – Color fastness to rubbing)

- SATRA TM170(Standard method for color fastness to rubbing)

- AATCC 8(Colorfastness to Crocking: AATCC Crockmeter Method)

- ISO 105-X12(Textiles – Color fastness to rubbing)

- GB/T 3920(China’s national standard for color fastness to rubbing)

Main Parameters

| Parameter | Specification |

|---|---|

| Number of Stations | 4 (simultaneous testing of 4 samples) |

| Friction Head Load | 9 N (standard; adjustable 5–15 N for custom tests) |

| Stroke Length | 100 mm (adjustable) |

| Friction Speed | 60 ± 2 cycles/min (1 cycle = 1 double stroke) |

| Sample Dimensions | 140 × 50 mm (standard leather/textile swatches) |

| Abrading Fabric | Standardized cotton cloth (e.g., Crockmeter cloth per ISO 105-F10) |

| Power Supply | 220V/50Hz, 60W |

| Dimensions | 500 × 350 × 300 mm (L × W × H) |

Working Principle

- Sample Mounting: Leather or fabric specimens are clamped into 4 individual stations.

- Friction Head Application: A weighted abrading cloth (9 N load) moves back and forth across the sample surface.

- Cycle Execution: The machine completes 50–100 cycles (customizable) to simulate wear.

- Color Assessment: Post-test, the abrading cloth is evaluated for dye transfer using agray scale (AATCC EP1, ISO 105-A03)or spectrophotometer.

Test Principle & Applications

- Color Fastness Evaluation (ISO 11640/AATCC 8):

- The abrading cloth is rated on a 1–5 gray scale (1 = severe staining, 5 = no transfer).

- Pass/fail criteria depend on industry standards (e.g., ≥4 for automotive upholstery).

- Key Industries:

- Leather Goods: Validating color retention in handbags, shoes, and furniture.

- Automotive: Testing seat covers, steering wheels, and interior trims.

- Apparel: Assessing dye stability in jackets, gloves, and accessories.

Send product request

Other supplier products

| seat foam compression hardness tester-QINSUN | Applicable standards: GB/T 6670-2008"Determination of falling ball resilience of soft foam polymeric materials" : This standard specifies the test... | |

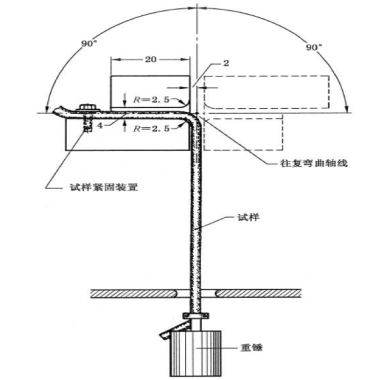

| (Changan) Automobile wire and wire bending testing machine-QINSUN | Standard: DIN 51211 and ISO 7801 Scope of application: Changan Automobile "JT automobile low-voltage wire technical conditions" standard Techni... | |

| Automotive interior Flame Retardant Tester | StandardsGB 8965-1998 Flame-retardant protective clothing Appendix B test methods for flame exposure times of seamsTB/T 3138-2006 Technical speci... | |

| Taber Abrasion Tester (Double-Head) | Standards DIN Standards: DIN 53754 (plastics), DIN 53109 (paper/board), DIN 52347 (glass/plastics) ASTM Standards: ASTM D1044 (transparent plas... | |

| Geomembrane Environmental Stress Cracking Resistance Tester | Scope of application: The stress cracking strength of polyolefin geomembrane was measured and evaluated by notch constant load tensile test. Durin... |

Same products

| Briefly describe the importance, core functionality and how to implement a hospital clock system solution | Seller: California Triangle | In the healthcare industry, precise time synchronization is critical. Every second can be a matte... | |

| Sand and Dust Test Chamber for Automotive Connectors | Seller: Standard International Group (HK) Limited | Operating Conditions: Ambient temperature: 5°C~+28°C (average temperature within 24 hour... | |

| Automotive Connector SO₂/H₂S Corrosion Test Chamber | Seller: Standard International Group (HK) Limited | Standards: GB/T 10587-89. GB/T 2423.9-93: Chinese national standards for sulfur dioxide corrosio... | |

| Automotive Connectors Salt Spray Tester | Seller: Standard International Group (HK) Limited | Applicable Standards: Neutral Salt Spray (NSS) Tests: GB/T2423.17. ISO 3768/3769/3770. ASTM B117... | |

| Air - tightness Testing Device for Automotive Connectors | Seller: Standard International Group (HK) Limited | Main Functions: 1. Provide stable positive and negative pressures for testing the air - tightnes... |