BKNET-0102 Welded Pipe Eddy Current Flaw Detector

Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. At the same time, we need to be clear that the welded pipe is, in general, the steel pipe that we usually say, which is a welded steel pipe.

Eddy current weld testingis a non-destructive testing technique for detecting component defects by using the principle that the eddy current induced by the AC electromagnetic coil on the surface of the metal member encounters a defect. The oscillating current is generated in the conductive member by the excitation coil by the principle of electromagnetic induction, and the amount of change in the eddy current is measured by the detecting coil, thereby obtaining information on the component defect.

Eddy current testing is a non-destructive testing technique in which an alternating current electromagnetic coil induces eddy currents on the surface of a metal member. It is suitable for the detection of defects in conductive materials, including ferromagnetic and non-ferromagnetic metal materials.

BKNET-01�2 NDT weld testing equipment is used for on-line and off-line inspection of welded pipes. It has high sensitively to axial defects such as unwelded welding, dark spots and open cracks. In the production process, products are caused by welder failure. Slow and long-term injuries can be reliably detected.

BKNET-0102 Welded Pipe Eddy Current Flaw Detector performance

|

Detection channel |

Double channel |

|

Detection speed |

1~500m/min(online) |

|

Frequency range |

100Hz-1MHz |

|

Gain |

0~99dB,step0.1dB |

|

Phase rotation |

0-360°step1° |

|

High pass |

|

|

Low pass |

1Hz~10000Hz |

BKNET-0102 Welded Pipe Eddy Current Flaw Detector Features:

High precision end and end-to-tail signal removal

High precision real-time, delayed alarm output

Fast digital/analog electronic balance

Memory track delay blanking function

Non-equal amplitude phase/amplitude alarm domain

Remote automatic help system

Synchronous alarm output for internal and external clock control

BKNis an eddy current testing benchmark enterprise and has long been committed to the development and production of bearing hardness and crack eddy current screening equipment. If you want to know more details or want a quotation, just feel free to contact us!

Send product request

Other supplier products

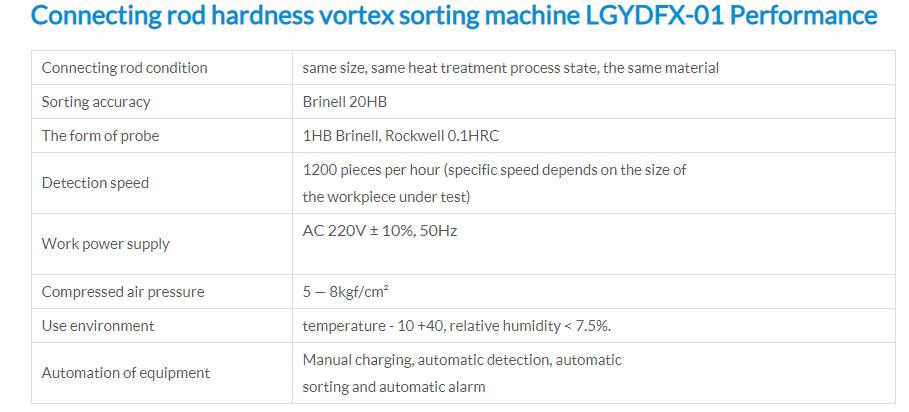

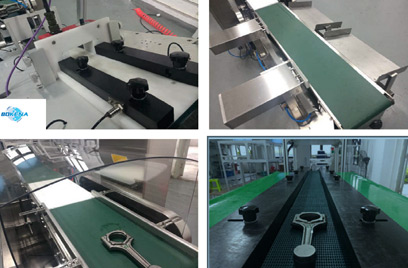

| Connecting rod hardness vortex sorting machine LGYDFX-01 | The connecting rod hardness eddy current testing machine has a calibration device, input compensation parameters, automatic/manual temperature comp... | |

| Portable Magnetic Flux Leakage Testing Equipment | MFLequipmentrefers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... | |

| Application of Ndt Inspection Equipment | Ndt inspection equipmentis widely used in industry, such as nuclear industry, weapon manufacturing, machinery industry, shipbuilding, petrochemical... | |

| Eddy Current Testing Equipment | ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals ... |

Same products

| Lost Wax Casting Y Piece FlowSplit Fitting | Seller: Qingtian Baoli Casting Co., Ltd. | Lost Wax Casting Y Piece FlowSplit Fittingis produced through the lost wax casting method, enabli... | |

| Mini Nitrogen Generator | Seller: Shandong benyuan international trading co,.ltd. | Mini Nitrogen Generator Mini Nitrogen Generator Are you looking for a reliable, cost-effe... | |

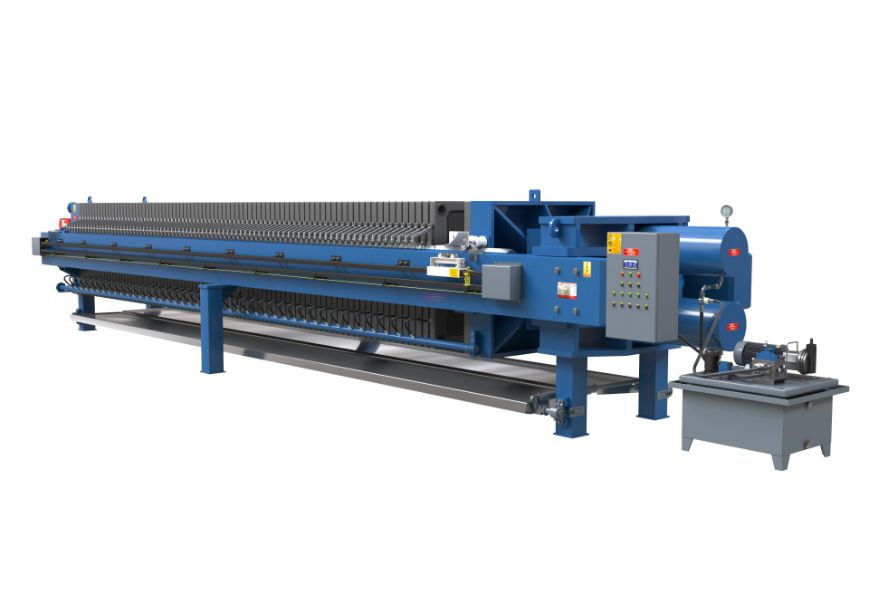

| filter press in chemical industry | Seller: ZHONG DA BRIGHT FILTER PRESS CO., LTD. | Our for Chemical Industry is designed to meet strict safety and environmental standards, en... | |

| Laser Cutting Service China METAL FINISHING | Seller: Dalian Zhuosheng Technology Co., Ltd | Laser Cutting Service ChinaMETAL FINISHING Laser Cutting Service ChinaMETAL FINISHING-China Dal... | |

| Intake Manifold in Car Engine | Seller: SDZ AUTO PARTS CO.,LTD | The car intake manifoldis a component of an automobile engine that supplies a mixture of air to d... |