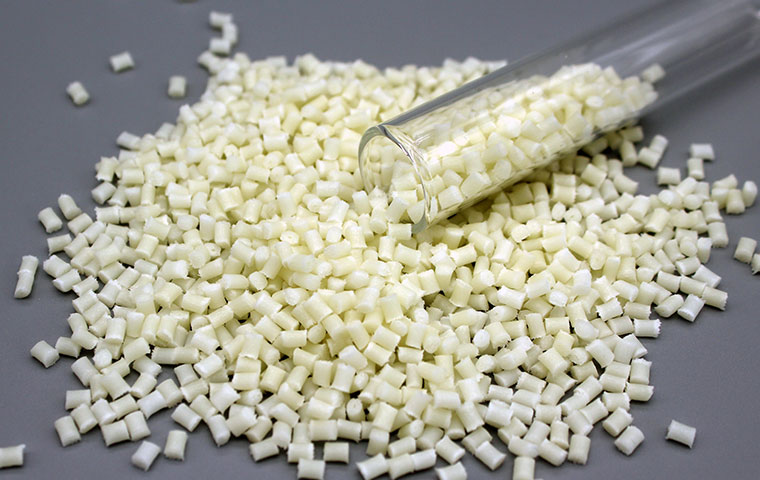

Anti-mold Masterbatch for Engineering Plastics

Anmei, one of the professional plastic master batch manufacturers, has a range of customized masterbatches available which incorporate antistatic masterbatch, for use in different polymers and applications. It is to prevent unbearable odors and unsightly staining.

The Development Process of Anti-Mold Masterbatch

The Anti-mold masterbatchdevelopment process begins with your end-usedproducts. We select the proper resin, colorants, additives, modifiers and fillers to meet your performance and test requirements. Once the properties are approved by your, samples may be produced for pre-production trials.

Benefits of conductive masterbatch

Moldy plasticsemitan unpleasant smell and make them undesirable or unusable due to the decreasing of the aesthetics of the product surface. When an anti-mold masterbatch was used, it can inhibit mold growth and prevent odors and stains. It includes as its primary function the removal of micro-bacteriological charges and above all the removal of mold and fungi. The working principle of anti-mold masterbatch is different from that of antimicrobial masterbatch. Just the right anti-mold masterbatch based on your end-use areas can reach a certain level of effect.

Application of Anti-mold Masterbatch

Anti-mold masterbatch applications can be numerous and can be applied to ABS, PA, PP, PE, and other polymers and manufactured in an injection molding, extrusion, and blown film. The strong protective effect of this antiblock masterbatchis suitable for use in the sector of water box of floor scrubber.

Want to buy masterbatch, contact us.

There are many masterbatch suppliers, but we are one of the best choices for you.

Send product request

Other supplier products

| PA66 GF30 Halogenated FR (A2014F, A2114F) for Engineering Plastics | PA66 GF30FR is a Nylon 66 with 30% glass-fibers and flame retardant halogenated. Typical Application of PA66 GF30 Halogenated FR (A2014F) The adv... | |

| ABS Engineering Plastic in Anmei | ABS resin is a terpolymer composed of acrylonitrile, butadiene and styrene. ABS has the rigidity, chemical resistance and heat resistance of polyac... | |

| Color Masterbatch for Engineering Plastics | Color Masterbatch for Engineering Plastics As an engineering plastic company, Anmei serves customers with tailored-making solutions from standard ... | |

| Engineering Plastic & Masterbatch in Anmei | ANMEI, YOUR PROFESSIONAL PLASTIC SUPPLIER! Contact US TODAY ANMEI focuses on supplying the 5G New energy and intelligence appliance market with en... | |

| PA66 GF15 With High Tensile Strength (A2307C, A2317C) for Engineering Plastics | PA66GF15is a 15% glass fiber reinforced, toughened, polyamide 66 resin for injection molding Typical Application of Anmei GroupPA66 GF15 With Hi... |

Same products

| Defoamer Powder | Seller: Shandong Jufu Chemical Technology Co., Ltd. | Antifoaming agent powder primarily serves as an essential component in cement and concrete produc... | |

| PA66 GF35 (A2000G, A2011G, A2111G) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | PA66 is nylon 66, namely pa66_gf35is glass fiber. Generally expressed as PA66 GF35, that is, 35% ... | |

| PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, forinjection moulding. PA66GF3... | |

| PA66 GF30 Halogen-free FR (A2015F) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | Material PA66 GF30FR is a PA66 with 30% glass-fibers and flame retardant free of halogens. This t... | |

| PA66 GF30 Halogenated FR (A2014F, A2114F) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | PA66GF30FR is a Nylon 66 with 30% glass-fibers and flame retardant halogenated. Typical Applic... |