Manifold

Ram BOP

Single and double ram type BOPs are widely used in oilfield and offshore platform. They have the features of compact structure, easy handling and reliable seal. The pipe ram adopts the pressure increasing seal way, which makes it seal drill tool rapidly and efficiently, even remain its seal effect after the disappearance of fluid control pressure.

The open or close of ram preventor and ram replacing are both hydraulically controlled. The onsite replacing of pipe ram and sealing parts saves much time.

•Driving mode:Manual & hydraulic

•End connection:Flanged and bolted

•Working pressure:2000~10000PSI

•Nominal bore:90mm、120mm、179.4mm、279.4mm、346mm

•Executive standard: API 16A and relevant specification

Annular BOP

In case of blowout and well-sealing is needed,high pressure oil coming from control system enters the bottom closing chamber from bottom inlet to push piston moving upward.The movement of piston forces tubber core to move upward along the sphere surface, then supporting ribs get closer to push the internal rubber towards the wellhead center to fulfill the function of sealing drill equipment or the wellhead. When unlocking the seal is needed,hydraulic oil pushes the piston moving downward and the rubber core will reset to its original under its elastic force.

Structure Characteristics

1.The connection between top cap and housing ,top and bottom ends adopt flanges and bolts.

2.Semisphere rubber core has many advantages,such as not easy folding back, big volume of rubber storage.Under the well pressure,the piston pushes the rubber core upward to form a funnel shape.The funnel effect of rubber core increases its sealing performance and life span.

3.Characteristics of the sealing structure

Choke and Kill manifold

Choke manifold and Killing manifold are the important well control equipments to carry out close balance drilling in petroleum exploration. During well drilling process, these equipments can keep oil reservoir from pollution and efficiently control well blowout. That product designs a manufacturing according to the API Spec 16 C standard, the machine function is good, sealing completely credibility, the function is well-found, operating convenience.

Main Technical Parameters

Name Choke Manifold Killing Manifold

Type JG35 YJG35 YJG70 YJG70A YJG35 YG70 YG70A

Main&side passage diameters 103×65mm

Working pressure 35MPa 70MPa 35MPa 70MPa

Working medium -29~121 ℃

Working medium ud oil (H 2 S)

Type of control Double wing

manual Double hydraulic Triple wing hydraulic Single wing with clea valve

Mud manifold

The mud manifold is applicable on land and forms a complete set with the drilling, Which working temperature is -29~121℃,medium is water or mud, and connections are threaded or flanged.

MAIN TECHNICAL PARAMETERS

Working Pressure psi(MPa) 2000~10000(14~70) Nominal Bore in(mm) 2~4 (50~100)

Product Specification Level PSL 1~3 Material Class AA~FF

Performance Requirement Level PR 1~2 Working Temperature P.U

(-29~121℃)

Other supplier products

|

|

Grapple Releasing Spear |

Grapple Releasing Spear

Grapple Releasing Spear Type LM is a simply constructed and high strength fishing tool by which fishing job is performed t... |

|

|

Fishing Magnet |

The Fishing Magnets are used to retrieve all types of small objects having magnetic attraction from bore hole bottoms. Such undrillable objects as ... |

|

|

Substructure |

Substructure

1. The substructure is divided into prizing-trailers, truck-mounted, entrusted Pack, me block, double-up, spin-up, and so on.

2. Box-... |

|

|

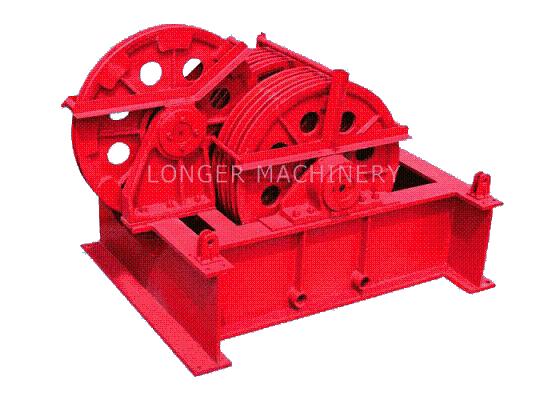

DrawWorks |

DrawWorks

The Single-shaft Electric Drawwork:

The drawwork is single-shaft with grooved drum structure, has less spare parts, small cubage, ligh... |

|

|

Crown Block |

Crown Block

The crown frame is made of high strength steel shapes.

Sheave grooves are hardened by medium frequency induction to provide extended ... |

All supplier products

Same products