Yacht Model Making Case Study

Project name:Yacht model

Material: ABS engineering plastics

Process: CNC machining

Post treatment: Painting, plating

Qty: 1 set

Advantages: high precision, fast speed and high processing efficiency

Production cycle: 15 days

Project requirements:

2, perfect assembly, fine surface treatment, smooth lines of finished products and even colors

Project Background

The birth of a yacht begins with a drawing. After a rigorous review, the model of the yacht is produced. This is the conceptual model of the yacht. The customer can easily make the appearance review by making the yacht model.

Project pre-stage analysis:

After receiving the design drawings sent by the customer, the production department holds a preliminary analysis meeting, and through the cooperation of various departments, detailed analysis of each problem that the product needs to pay attention to.

Process and material selection:

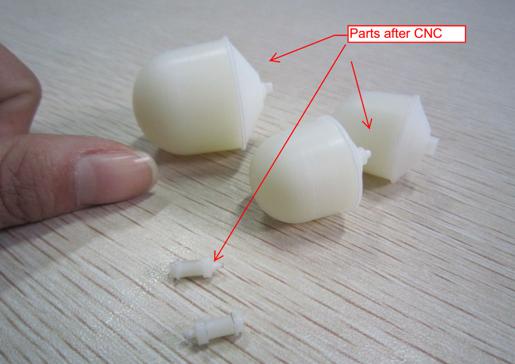

The hull and superstructure are mostly made of ABS engineering plastics as raw materials, and some small parts are made of metal stainless steel. Most of the manufacturing processes are done by CNC abs plastic machining. After processing, the model needs to be post-treated by grinding, painting, electroplating, etc. to enhance the appearance of the model.

Production process:

- ABS CNC machiningprocess, split the model to ensure that the components of each level can be processed; with the help of the software, the pre-analyst optimizes the assembly of the drawings and verifies the feasibility of the drawings. .

- abs precision machiningis completed, the parts are rough-assembled and necessaryly polished to ensure that the products are assembled correctly before painting.

Duch Groupcan provide customers with rapid prototyping china,CNC processing, 3D printing, product appearance processing (grinding, polishing, vacuun casting, spraying, silk screen, pad printing, electroplating, laser engraving, wire drawing, etc.) small batch personalized product customization, mass production and other services, which can help customers quickly verify the appearance of the product, help customers achieve high-quality sample manufacturing and china prototype manufacturing. If you have the above needs, please contact us!

Send product request

Other supplier products

| ProtoFab PF-M 150 | WIDE CHOICE OF MATERIALS This entry level SLM printer uses a broad choice of materials including stainless steel, Cobalt Chrome, Bronze, Titanium, ... | |

| Vacuum Casting Services | What is the Vacuum Casting? The vacuum casting technology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silicone m... | |

| What is Rapid Prototyping? | What is rapid prototyping china? Rapid prototyping is a kind of professional manufacturing technology that is used to produce high-quality entity m... | |

| What is a Mold? | What is a Mold? In industrial production, various types of presses and special tools mounted on the press are used to produce metal or non-metal ma... | |

| Reverse-Engineered Service | What is Reverse Engineering? Reverse engineering is to obtain the point cloud data of the physical model by using the three-dimensional digital sca... |

Same products

| Digital Blade Sign | Seller: Shenzhen Cosun Sign Smart-Tech Co. Ltd. | Digital Blade Sign The digital blade sign is a product developed from the traditional blade sign... | |

| Pylon Signs | Seller: Shenzhen Cosun Sign Smart-Tech Co. Ltd. | Pylon Signs Pylon signsare a type of upright wayfinding sign used in various facilities within c... | |

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... |