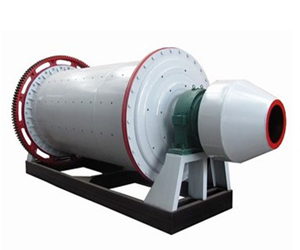

Intermittent Ball Mill

Intermittent Ball Mill is mainly used for materials, grinding, the fineness of the product is uniform, save power. The machine can be dry grinding, also may wet milling. This machine can according to the production need to adopt different kinds of lining board, in order to meet different needs. The fineness of grinding rely on the milling time on its own control. Motor start by reduced pressure, reduce the starting current, its structure is divided into this independent type. This product has less investment, more similar products , energy saving, novel structure, simple operation, the use of safe, stable and reliable performance, etc. It is optimal in ordinary and special material of mixing and grinding. Users can according to the material, hardness and production factors such as comprehensive consideration to choose the appropriate type, lining board and media type.

Intermittent Ball Mill is horizontal cylindrical rotating device,made of feeding, discharge,turn,transmission part (reducer, gear, motor, electric control)and other major parts. Outside is the gear transmission, two warehouse, grate ball mill. Hollow shaft adopts steel castings, lining can conversion, the slewing gear with cast roll teeth processing.

Operating principle:

Motor through deceleration device drive cylinder, cylinder body of crushed ore and steel ball in cylinder rotation by friction force and centrifugal force, after the lining to a certain height by gravity, it has thrown down and diarrhea, ore under impact and the grinding effect gradually being shattered, shattered ore of the layout of the discharge tube. Eduction of the mineral classification in the machine after the qualified products, coarse sand through join feeder back to the grinding ball mill Evenly feed the material continuously feeding machine, continuous ore by joint feeder evenly into the ball mill, the grinding materials continuously from vent. Intermittent ball mill is grinding equipment of continuous work 24 hours every day.

| Model |

Loader(t/c) |

Cylindern speed(r/min) |

Power(kw) |

Liner material |

| 600x700 |

0.05 |

50 |

2.2 |

Ceramic,silica,rubber,metal(powerbasedonthelining

materialandthedifferentgrindingmaterialswillbethedifferent) |

| 800x600 |

0.075 |

42 |

3 |

| 900x1200 |

0.2 |

38.5 |

5.5 |

| 1300x1500 |

0.5 |

33 |

7.5 |

| 1500x1800 |

1.2 |

28.5 |

11 |

| 1800x2000 |

1.5 |

24 |

15 |

| 2600x2800 |

5 |

16.5 |

37 |

| 3000x3800 |

10 |

14.5 |

57.2 |

| 3200x4600 |

15 |

13.5 |

75 |

Other supplier products

|

|

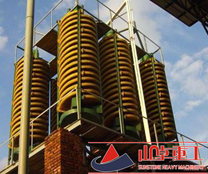

Spiral Chute |

Product advantage:This equipment applies to the size 0.3--0.02 mm fine material such as iron ore, ilmenite, chromite, sulfurous iron ore, zircon, r... |

|

|

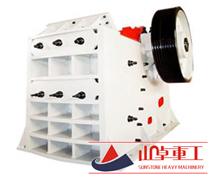

Jaw Crusher |

1.Good stability, high reliabilityMoving jaw Assembly adopts the high quality casting components,heavy eccentric axis also forging billets for proc... |

|

|

Powder Concentrator |

1.The material in the hierarchical indoor, under the action of double rotor strong cyclone and radial shear force, and the material dispersion is g... |

|

|

Intermittent Ball Mill |

Intermittent Ball Mill is mainly used for materials, grinding, the fineness of the product is uniform, save power. The machine can be dry grinding,... |

|

|

Spring Cone Crusher |

1.Special sealing,function reliablyPY series spring cone Crusher uses oil or water seal ways, and make the dust impurities enter the body, thereby ... |

All supplier products

Same products