One-Step Fabric Recycling Machine

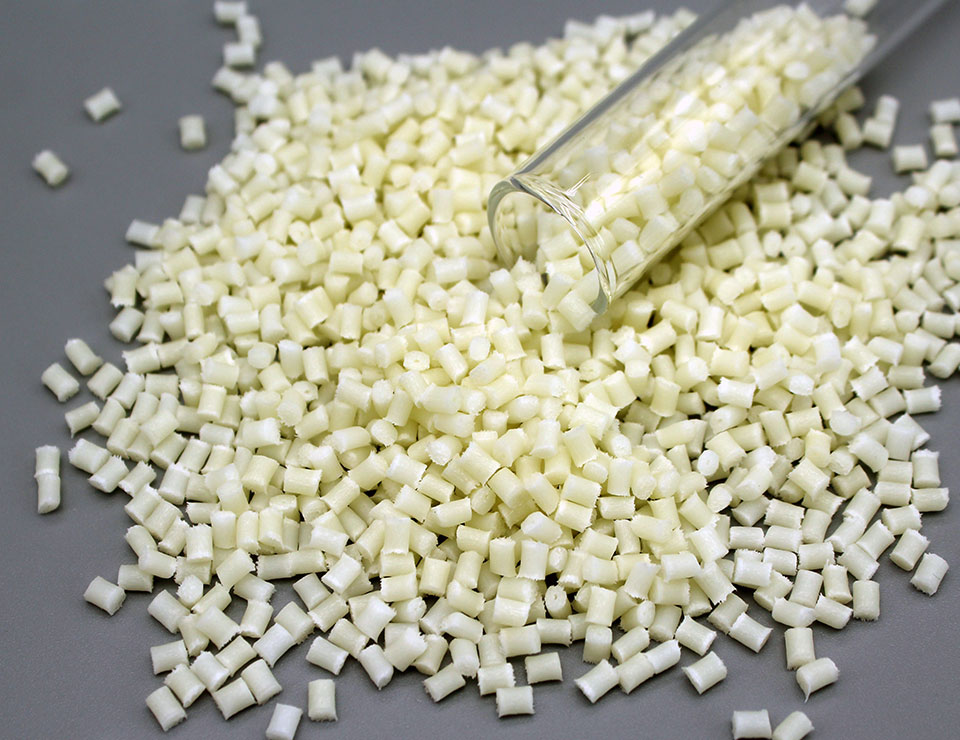

One-step waste fabric recycling machineis extrusion molding equipment together with waste plastics and auxiliaries to directly make trays, manhole covers, flower pots and other products.

One-Step Waste Fabric Recycling Machine Specifications

One-Step Fabric Waste Recycling Machine Features

The One-Step polyester fabric recycling machineis specially designed to process different materials like textile, leather, wood and plastic. It has a top-of-the-line control system that assists in managing all the processes and operations of the waste textile recycling machine. The system includes water pump, pressure gauge, simple control circuit and equipment feeder, thus making the non woven fabric recycling machineenvironmental friendly and economically viable.

The high-quality parts used to build this textile waste recycling machine make it a durable product which will serve you for many years. This gives you an advantage over other brands that offer similar products but with subpar quality.

Fabric Waste Recycling Machine Application

The fabric waste recycling machine can be widely used in paper, plastic and textile recycling field. It is a new green environmental protection equipment for textile, plastic, paper and other waste materials recycling, which is used for recycling the waste fabric into raw material for the production of iron wire, etc. Fashion fabric recycling machine is widely used for washing and recycling of various cloth waste. It can greatly improve the production safety, reduce labor intensity and save time in the daily work at the same time, improve working conditions and environment. This woolen cotton yarn fabric recycling machineis equipped with advanced technology and has good performance. It also meets international standards and can be widely used in many countries around the world, so it has good prospects for export. Our textile waste recycle machine is used for the recycling of all kinds of fabric waste, such as coat and bag slippers, cotton felt and felt made of cloth, which can be turned into plastic tape and other raw materials. Cloth recycling machine can efficiently solve the problem of plastic waste in daily life.

Why Choose Fabric Waste Recycling Machine?

According to incomplete statistics, more than 1 billion tons of used clothes are dumped into landfills worldwide every year, generating 2 million tons of carbon dioxide emissions every year. What is even more shocking is that by 2030, the impact of old clothes on climate warming will increase to 49%, and climate warming will make more and more polar bears homeless and even extinct. What can we do for polar bears in symbiosis on this blue planet?

A 2008 study conducted by the Bureau of International Recycling (BIR) at the University of Copenhagen in Sweden concluded that every kilogram of old clothing recycled can reduce carbon dioxide emissions by 3.6 kilograms. This also means that for every additional piece of old clothing recycled, we can slow down some more of the rate of global warming, and we have more hope of preserving a glacier for polar bears.

In view of this, our waste fabric recycling machine company has invested a lot of manpower and material resources in the research of waste textile recycling machine. A complete set of profile extrusion fabric recycling machine has been developed,and the waste spinning and granulation are added to the one-step garments waste cloth recycling machine together with waste plastics and auxiliaries to directly make trays, manhole covers, flower pots and other products.

If you want to know more details of fabric recycling machine price, please contact us.

As one of plastic recycling machine manufacturers, we can offer sorts of plastic recycling machine for sale, anything you need, please leave us a message.

Send product request

Other supplier products

| Double-Station Two-Step Extrusion Molding Machine for Mixed Waste Hard Plastics | The double-station recycled plastic extruder is twice as efficient as the single-station, and the price of recycled plastic extrusion machine is 3/... | |

| Single-Station One-step Extrusion Molding Machine for Mixed Waste Plastic Films | The fully automatic one-step plastic film extrusion equipmentis our company's patented product. Fully automatic film extrusion equipment: mainly us... | |

| Plastic Recycling Granulator Machine With Water | The plastic recycling granulator machine with water adopts a special screw design and different configurations, the equipment is composed of three ... | |

| One-Step Extrusion Machine for Waste Fabric | One-step ffabric waste recycling machineis extrusion molding equipment together with waste plastics and auxiliaries to directly make trays, manhole... | |

| Mulch And Greenhouse PE Film Washing Machine | According to the statistics of China Urban Environmental Sanitation Association, my country produces nearly 1 billion tons of garbage every year, i... |

Same products

| Medical Plastic Parts | Seller: Packson Mold Co.,Ltd | Project Management To be a qualified medical plastic components manufacturer, the most advanced ... | |

| PA66 GF15 Heat Stabilized (A2006C, A2016C) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | PA 66 GF 15is a 15% glass fiber reinforced, heat-resistance, polyamide 66 resin for injection mol... | |

| PA66 GF | Seller: Suzhou Anmei Material Technology Co., Ltd | Anmei focuses on the production of modified engineering plastics. We have polyamide pa6 6gfmodif... | |

| Nylon6 PA6 | Seller: Suzhou Anmei Material Technology Co., Ltd | Other than fiber-reinforced pa6 polyamide, the unreinforced nylon type 6 produced by Anmei, one o... | |

| Nylon 66 Pa66 With High Tensile Strength (A2307X01, A2317X01) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | Using Polyamide 66 as the basic resin, the tensile strength of nylon 66 is obtained by blending a... |