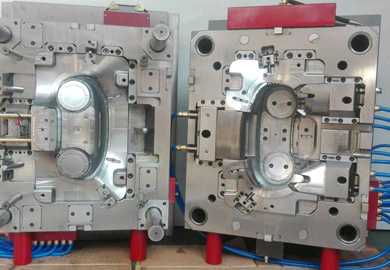

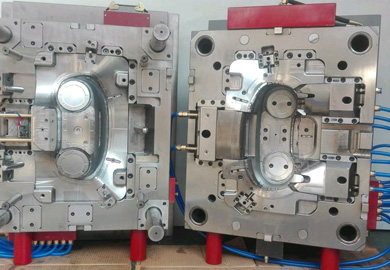

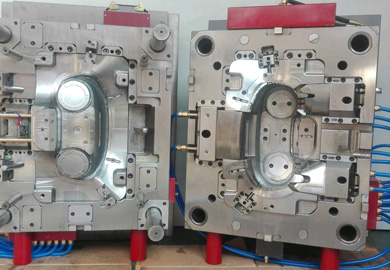

Home Appliance Mould

Home appliance mould combines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, household appliances are closely related to home appliance mold.

As a leading home appliance plastic injection moulding manufacturer, GM-TECH makes sure all the products made by moulding meet the demanding requirements of our customers. We are devoted ourselves improving the service and home appliance mouldquality continuously.

Features of Home Appliance Mould

With the development of the home appliance industry, applications of home appliance mold are popular in the injection process such as fan mould, computer mould, air conditioner mould, refrigerator mould, and so on. So why are there wide applications of home appliance mold?

High precision and long service life

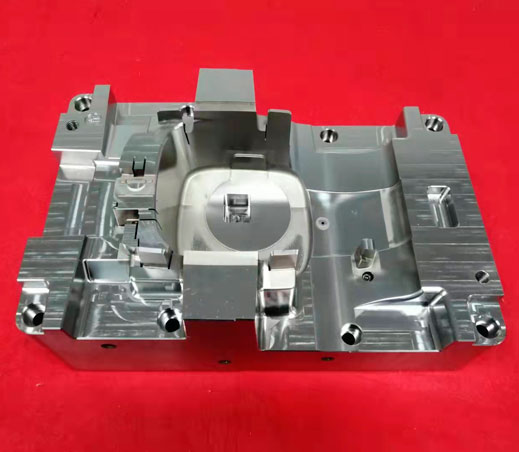

The home appliance mould adopts an inlaid or fully assembled structure, improving the high processing accuracy of plastic injection moulding parts.

Off-site design and off-site processing

The china home appliance moldprocess requires to meet customer needs and provide mass production by off-site design and off-site processing.

Short processing time

For injection household appliances mouldparts, most of them are matched with other injection molding types, which can save processing time.

How does Home Appliance Mould Work?

Before we explore the working principle of home appliance mould, the first stage is to make a mould. Then the material is fed into a heated barrel and mixed using a helical-shaped screw.

Heating bands make the material melt. Next, the mixed materials, generally metal and plastic, are fed to the cavity of the home appliance mould to keep cooling. Finally, the shape of the home appliance mould is formed as we designed.

GM-TECH is an experienced plastic injection molding factory, we provide plastic parts injection molding, plastic moulded partsand etc. Contact us to know more about plastic mold technology.

Send product request

Other supplier products

| 2K Mould | 2k injection molding is a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines t... | |

| Mould Slide | GM-TECH, a plastic injection manufacturer, has been manufacturing tools for injection molding of plastics for various industries for more than 10 y... | |

| Medical Equipment Mould | Medical products include syringes, and internal and external parts of medical equipment. Features of medical device injection molding Our company ... | |

| Mould Component | Mould Component Mould Componentsare also a part of the mould. GM-TECH not only produces precision moulds but also provides customers with high-pre... | |

| Multi Cavity Mould | A multi cavity moldis known as a mould with multiple cavities. The multi-cavity mold consists of a multi-cavity of different plastic parts. Thou... |

Same products

| ALP_606 | Seller: Leetop Technology (Shenzhen) Co., Ltd. | Leetop_ALP_606 is an embedded artificial intelligencecomputer based on NVIDIA Orin NX core board,... | |

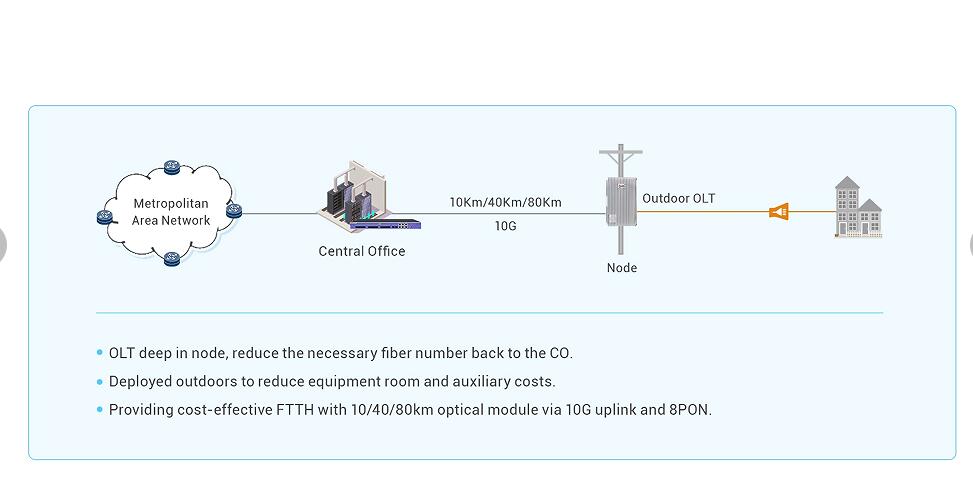

| OUTDOOR OLT | Seller: Shenzhen C-Data Technology Co., Ltd. | Deploying outdoor cabinet OLTdownward, closer to users 8 PON PORTS GPON OLT FD1608Y 2*10G SFP+... | |

| Optical Transport Networking | Seller: Shenzhen C-Data Technology Co., Ltd. | C-Data Optical Transmission Network (OTN products) products are designed to build professional ne... | |

| Hybrid Fiber-Coaxial | Seller: Shenzhen C-Data Technology Co., Ltd. | C-Data Hybrid Fibre Coaxial HFCproducts provide high-quality image, digital or signal transmissio... | |

| ONU | Seller: Shenzhen C-Data Technology Co., Ltd. | C-Data XPON ONU Enjoy the Rapid Internet Large Bandwidth | High Reliability | Easy Management... |