Evaporation Technology

Effectively reduce the tower kettle temperature and improve product quality and yield.

Evaporation TechnologyIntroduction

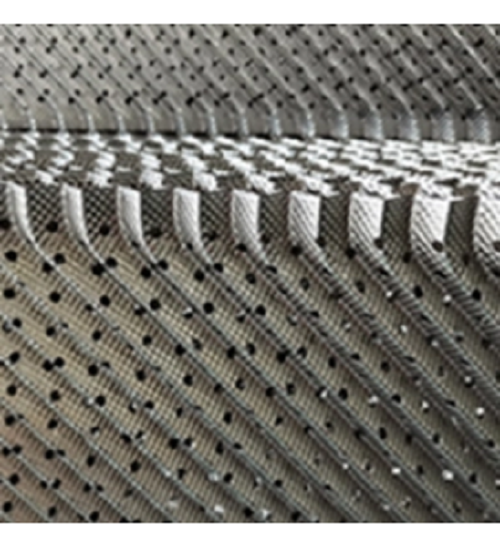

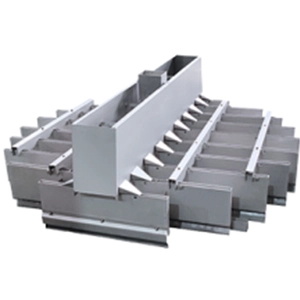

Falling Film Evaporationis a process in which the liquid feed is introduced into the upper header box of the heating chamber of a falling film evaporator, and then evenly distributed to each heat transfer tube by a liquid distribution and film-forming device. Under the effects of gravity, vacuum induction, and gas flow, the liquid forms an even film that flows down from top to bottom. In the distillation unit, the vapor phase directly enters the tower for distillation, while the liquid phase is discharged from the separation chamber or circulated back into the evaporator by the pump.

Technical Principle of Evaporation Technology

Design conditions: we use the most safe and stable falling film reboiler model in present day, and the falling film introduces the multi-level distribution form including the distribution plate and the film distribution header.

Process Calculation: based on the calculation of advanced simulation software, key parameters such as gasification rate, circulation volume, flooding factor, gas-phase rate, heat exchange area, etc. are determined.

Distributor/Calculation of Film Distribution Header: various hydraulic models are conducted to design distribution system under specific operation conditions, further more hydraulic calculation is operated with independent software.

Characteristics of Evaporation Technology

1

Design conditions:

We use the most safe and stable falling film reboiler model in present day, and the falling film introduces the multi-level distribution form including the distribution plate and the film distribution header.

2

Process Calculation:

Based on the calculation of advanced simulation software, key parameters such as gasification rate, circulation volume, flooding factor, gas-phase rate, heat exchange area, etc. are determined.

3

Distributor/Calculation of Film Distribution Header:

Various hydraulic models are conducted to design distribution system under specific operation conditions, further more hydraulic calculation is operated with independent software.

4

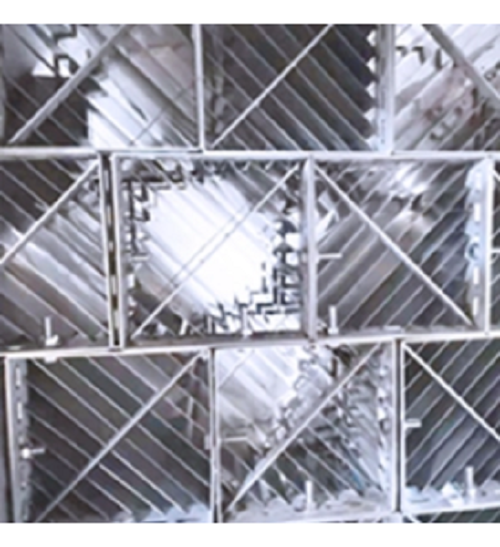

With rich experience and advanced technology, DODGEN falling film evaporator has been applied in various fields of heat-sensitive substances separation, the temperature of tower kettle is reduced, thus improving product quality and yield, and obtaining positive feedback from customers.

Applications of Evaporation Technology

In the evaporation and rectification section of heat sensitive substances, MVR system evaporator is particularly suitable for typical applications,such as:

MDI distillation

Vitamin E rectification

Ethylene glycol distillation

Hydrogen peroxide rectification

Nylon 11 distillation

Solvent recovery

MVR evaporation

And many other fields such as petrochemical, medicine and food.

For more informationabout chemical process pdf, please feel free to contact us!

Send product request

Other supplier products

| Hydrocyanic Acid (HCN) | Process optimization and improvement in reaction, a new generation of hydrocyanic acid synthesis technology in the world. Characteristics of hyd... | |

| Evaporation Technology | Technical Principle of Evaporation Technology Characteristics of Evaporation Technology 1 Design conditions: We use the most safe and stabl... | |

| Column Internals | Columns Internals A strict quality management system guarantees the product quality and delivery time of the project. Characteristics of Packed... | |

| Devolatilization Technology | DSXL devolatilizationtechnology improves product quality and reduces cost. Technical Principle Of Devolatilization Technology devolatilization ... | |

| Gas-liquid Separator | Complete liquid nitrogen separatorproduct chain has been considered to customize separation scheme for customers. Technical principle Of gas liq... |

Same products

| Trimellitic anhydride 97% | Seller: Yufeng International Group Co., Ltd | Trimellitic anhydrideis a 2-benzofuran compound having oxo groups at the 1- and 3-positions and a... | |

| Isobutyric Anhydride CAS 97-72-3 | Seller: Yufeng International Group Co., Ltd | Product Name: Isobutyric Anhydride CAS No.: 97-72-3 Purity: 99% Molecular Formula: C6H10O3 Mo... | |

| Isobutyric Acid CAS 79-31-2 | Seller: Yufeng International Group Co., Ltd | Product Name:ISOBUTYRIC ACID Synonyms: 2-Methylpropanoic acid 79-31-2 Isobutanoic acid 2-Met... | |

| 2-Amino-2-methyl-1-propanol(AMP)CAS:124-68-5 | Seller: Yufeng International Group Co., Ltd | AtYufeng, a trusted 2-Amino-2-methyl-1-propanol Factory & Supplier, we prioritize quality and... | |

| Dimethyl sulfoxide (DMSO) CAS: 67-68-5 | Seller: Yufeng International Group Co., Ltd | Yufengis one of the leading dimethyl sulfoxide suppliers and also a professional such manufacture... |