Refractories the most important performance is the anti-erosion ability

The part of the clarification that is in contact with the glass is in the same environment as the glass in the melting part, except that this part is usually operated at a much lower temperature. The upper structure of these parts of the maximum temperature is generally about 1399 ~ 1454 ℃, while the maximum temperature of most glass may reach 1399 ℃. There is often greater flexibility in choosing refractory materials for these locations because erosion rates are much lower here. However, the more the liquid glass flows toward the forming end of the furnace, the more the quality of the glass is affected by defects in the refractory material. The main reason for this is that the glass in these areas has a high viscosity and at this lower temperature it is difficult for glass to assimilate solid or gas defects originating from the refractory. In addition, the glass does not have much time to ask to complete the process of assimilation of the above defects. ② fluid hole. ③ bridge walls and side walls. ④ feed through the entrance. ⑤ bottom of the pool. 4 Clarification Department of the upper structure ① Overview. Similarly, this part of the temperature is much lower than the melting part. Clarification of the Ministry of the superstructure environment largely depends on the structure of the lattice wall, that is, the end wall and the melting part of the way separated. When using an open cell wall structure, steam condensation may occur due to the conditions in the melting section. The superstructure refractory material reacts on the surface of its refractory material due to its relatively cool area. In general, erosion is caused mainly by alkali vapor. After completely isolating the atmosphere of the fusing part and the fining part, only a very small amount of vapor escaped from the surface of the glass liquid to erode the refractory material in this area. Borosilicate glass furnace does not comply with this law, where the surface of the glass continuously release volatile sodium borate, even in the material so. In general, the best practice for borosilicate glass furnaces is the use of zirconium-based refractory materials or the use of silica-based refractory materials.

Other supplier products

|

|

Refractory raw materials processing procedures |

Refractory raw materials processing is to enter the factory of various shapes and sizes of refractory raw materials (including raw ore and clinker)... |

|

|

Mullite Bricks |

Description:Mullite brick IS characterized by good high temperature resistance and good thermal shock resistance, whick comes into being mullite th... |

|

|

Factors to consider when selecting insulation materials |

In choosing the insulation material for industrial furnaces, it is necessary to have a good understanding of the properties of the material itself ... |

|

|

Fused Cast AZS TY-AZS33 |

Fused cast AZS 33# block has dense micro structure which ensures its great resistance in glass liquid, thus you don’t have to worry about the... |

|

|

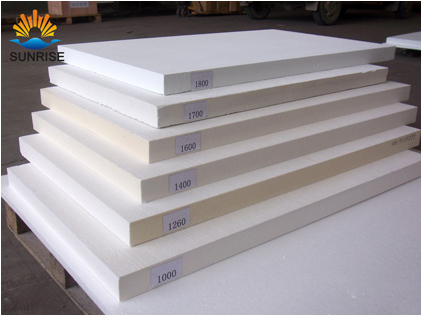

Ceramic Fiber Board |

Application:♦ Ceramic Fiber Board is made of Alumino-Silicate fibrous wool by vacuum forming process.♦ Furnace with high temperature an... |

供应产品

Same products