MFL-7389 Tube Magnetic Flux Leakage Detector

Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing tubing. It can ensure the quality of oil and water wells to prolong the inspection cycle, reduce the rework of operations and reduce operating costs.

As an important process in the tubing repair test line, the flaw detection can accurately and effectively detect the defects in the manufacture and use of the inner and outer wall and the pipe body of the oil pipe to ensure the repair quality of the oil pipe.

Fundamental of MFL-7389 Tube Magnetic Flux Leakage Detector

When the detected tubing is saturated and magnetized, the magnetic field lines are distorted by the magnetic lines of force at the defect blocking defect, and a part of the magnetic lines leak out of the inner surface of the tube rod to form a leakage magnetic field, and the electromagnetic detecting method for detecting the leakage magnetic field by the detecting element is detected. Magnetic flux leakage inspection.

The leakage magnetic field picked up by the probe from the defect is amplified and converted into a digital signal, and then visually reflected by the flaw detector to the display to display the defect signal from the flaw detector, and directly determine the defect type and size of the detected tube rod.

¢73 and ¢89mm tubing eccentric wear and corrosion pits are detected, automatic detection, automatic alarm, automatic identification, automatic alarm.

MFL-7389 Tubing Magnetic Flux Leakage Detector Brief Introduction

Our company's new MFI tube magnetic flux leakage inspection machine has high sensitivity to very small defects. It can effectively detect defects such as corrosion pits, eccentric wear on the inner wall of the tubing, thinning of tubing wall, etc.

Moreover, the testing speed is fast and pollution-free, and the detection is fully automated. The computer display screen is used to display the detection curve, automatic alarm, marking (defect of steel pipe), grading of tubing (grade I, II and scrap).

BKNis aprofessionalultrasonic testing equipment manufacturers. We provide Eddy Current Testing, Magnetic Flux Leakage Testing, mfl tube inspection, mfl tubeand so on. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Portable Magnetic Flux Leakage Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... | |

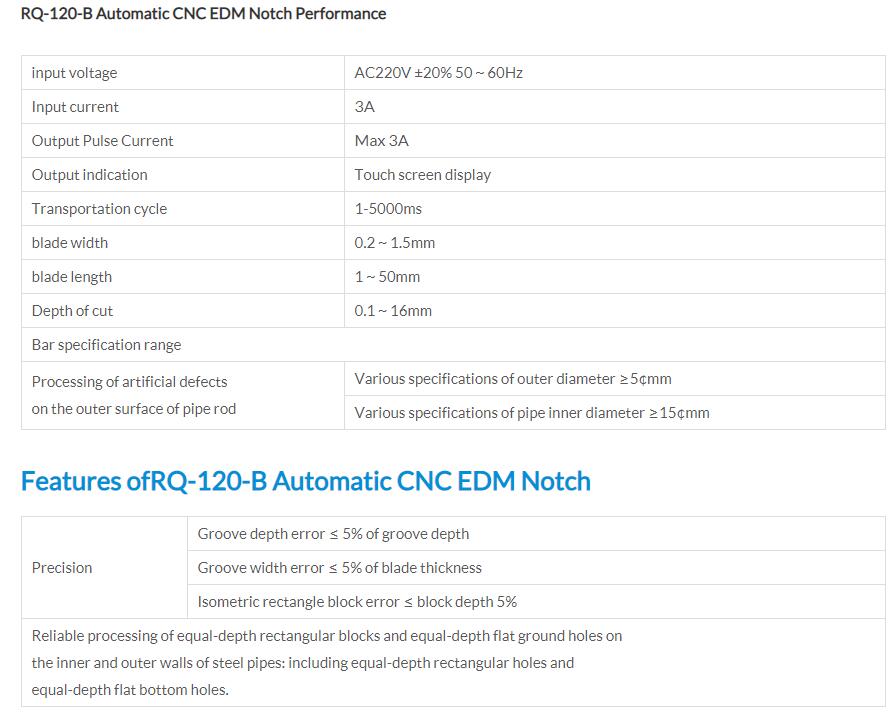

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| BKNET-999H Copper Tube Eddy Current Flaw Detector | BKNET-999H Copper Tube Eddy Current Flaw Detector brief Eddy current testing is a non-destructive testing technique in which an alternating curre... | |

| RQ-120-B Automatic CNC EDM Notch | BKNis one of professional ultrasonic testing equipment manufacturers. We provide Magnetic Flux Leakage Testing, eddy current testing and so on. Wan... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |