Wireless Transmission Pipe Ultrasonic Flaw Detector

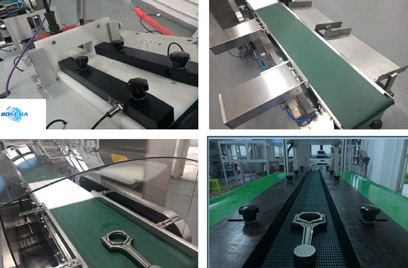

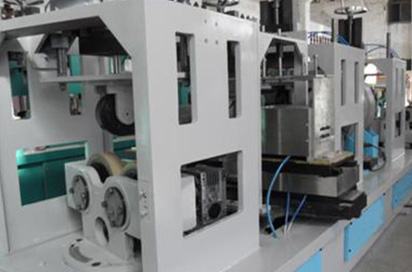

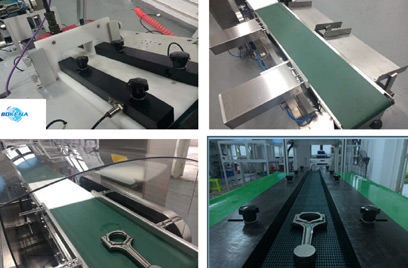

The ultrasonic pipe testing equipmentsystem is suitable for the automatic detection of various internal and external defects of steel pipes. The principle of ultrasonic flaw detection is that after the ultrasonic wave is coupled into the steel pipe through water, the incident propagation will cause ultrasonic reflection when there is a defect in the pipe. The ultrasonic instrument will alarm the ultrasonic reflected signal after realizing the signal to realize the automatic detection of the defect; Transmission ultrasonic pipe testing equipmentis currently the advanced detection equipment in China.

Wireless Transmission Pipe Ultrasonic Flaw Detector Introduction

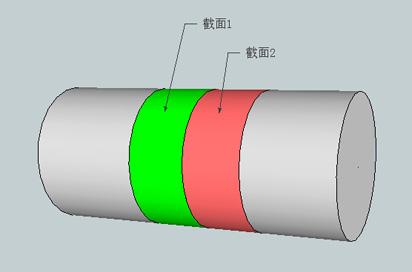

Rotating probe configuration

A total of 3 probe adjustment frames are placed on section 1 at 120°apart. Each of the adjustment frames is equipped with a 2-channel combined ultrasonic line focusing longitudinal probe to detect longitudinal defects of the steel tube in a clockwise direction.

Detection of defects: Vertical and vertical defects in the steel pipe are detected in a clockwise direction.

Center frequency: 5.0MHz±10%

Coupling method: water immersion method

Quantity: 3 sets of probes, each consisting of 2 wafers. These 3 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

A total 3 probe adjustment frames are placed on section2, separated by120°, and a 2-channel combined ultrasonic line focusing longitudinal probe is arranged on each adjustment frame to detect longitudinal defects of the steel pipe counterclockwise.

Detection of defects: counter-clockwise detection of longitudinal defects inside and outside the steel pipe.

the center frequency: 5.0MHz ± 10%

coupling method: water immersion method

Quantity: 3 sets of probes, each consisting of 2 wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

Defect detection standard

Inspection of Longitudinal and Transverse Defects in Ultrasound Steel Pipe: GB/T5777-2008 L2(C5) Standard

Wireless Transmission Pipe Ultrasonic Flaw Detector Performance

|

Number of channels |

12channels |

|

Flaw detection speed |

40m/min |

|

Total gain |

100dB,step 0.5dB |

|

Working mode |

Single probe transmitting, receiving or dual probe transmitting and receiving separately |

|

Sensitivity margin |

≥50dB |

|

resolution |

≥26dB |

|

Dynamic range |

≥30dB |

|

Scanning range |

0~5000mm |

|

Frequency range |

|

|

Sampling range |

250MHz |

|

Repeat frequency |

Signal channel100Hz~4KHzadjustable |

|

Vertical linearity |

≤2% |

|

Horizontal linearity |

≤1% |

|

Detection method |

Full-wave, positive half-wave , negative half-wave |

|

Gate setting |

3 gates per channel, A and B are defect gates, and c is an Interface tracking gate |

|

Alarm indication |

Alarm color display and audible alarm for each channel A, B, C |

|

Delay alarm |

Two ways, Delay time0.1~10S, step 0.1Swaveform storage, the unlimited number for waveform playback, printing and report generation |

BKNis a professionalultrasonic flaw detector manufacturersand ultrasonic testing equipment suppliers. We provide Magnetic Flux Leakage Testing, ndt testing machine, eddy current testing, ultrasonic pipe inspection equipment, ut pipe testing, ultrasonic flaw detector machine, ultrasonic flaw detector probeand so on. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Magnetic Flux Leakage Testing Equipment | What Is Magnetic Flux Leakage Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leaka... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless.... | |

| MFL101 Tank Floor MFL Scanner | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from the main body of the computer mechanism the handle o... | |

| MFL-7389 Tube Magnetic Flux Leakage Detector | Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing t... | |

| Eddy Current Testing Equipment | Are you looking for a perfect eddy current testing machine manufacturer? BOKENAis one of the most professional eddy current test equipment supplier... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |