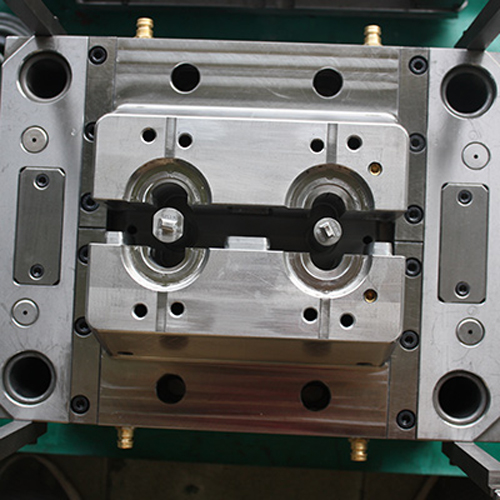

ABS Plastic Injection Mold 49443

Brief Introduction of Hanking ABS molds

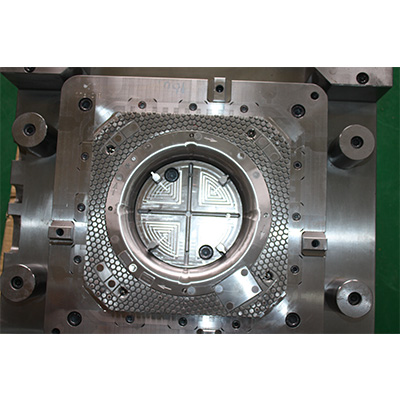

Mould Name: Plastic Injection ABS Molds

Part Material: ABS

Product Size: 172*123 mm

Product Description: clear window

Mould Cavity: 1 Cavity

Mould Size: 300*380*250 mm

Mould Cavity Steel: ASSAB 8407

Mould Injection System: hot runner

Mould Ejection System: Round ejector

Mould Cycle Time: 38s

Mould Life Cycle: 500,000

Lead Time: 42 working days

Mold export to: Europe

For ABS plastic part molds, HanKing will make good plastic injection mold design from wall thickness, draft angle, venting, ejector system, balance and a good runner.

Design for ABS Plastic Injection Molds

The wall thickness of the product is related to the flow length of the melt, production efficiency, and use requirements. The ratio of the maximum flow length of the ABS melt to the wall thickness of the product is about 190:1. This value will vary depending on the grade. Therefore, the wall thickness of the ABS product should not be too thin. For products has electroplating requirement, the wall thickness should be slightly thicker to increase the adhesion of the coating to the surface of the article. For this purpose, the wall thickness of the product is preferably between 1.5 and 4.5 mm.

When considering the wall thickness of the product, we should pay attention to the uniformity of the wall thickness, do not make big difference wall thickness. For the products to be electroplated, the surface should be flat without unevenness, because these parts are difficult to remove due to static electricity, which is difficult to remove. The fastness of the coating deteriorates. In addition, the presence of sharp corners should be avoided to prevent stress concentration. Therefore, it is advisable to use arcs for transitions such as corners and thick joints.

The draft angle of the product is directly related to the shrinkage rate. Due to the different grades, the different shapes of the product and the different molding conditions, the molding shrinkage rate has a certain difference, generally 0.3~0.6%, sometimes It is 0.4~0.8%, so its product molding size accuracy is high. For the ABS product, the draft angle is considered as follows: the core portion is 31° in the demolding direction, and the cavity portion is taken 4 (/1° 20' in the stripping direction. For products with complex shapes or letters and patterns, the draft angle should be appropriately increased.

Since the products surface finish has a great influence on the electroplating performance, any slight scratch on the surface will be apparently exposed after electroplating, so that no damage is allowed on the cavity. It is also required a large effective area for ejection, good synchronization of the multiple ejector pins in the ejection process, and uniform ejection force.

In order to prevent the occurrence of poor venting in the process of filling, cause melt burning, the obvious seam line and other problems, it is required to open a vent hole or venting groove in which the depth is not more than 0.04mm, so the gas can be exhausted.

HanKing Mouldis a professional two shot moulding ltd, we provide custom plastic molding china, injection moulding, plastic plate mouldand etc. Want to know abs injection molding processor how to mold abs plastic? Please contact us.

在线联系供应商

Other supplier products

| Plastic Mould for Air Guiding Fan | Mould Name: plastic injection mold Part Material: PA6 GF30 Product Size: 270*270*20 MM Product Description: Inlet Ring Mould Cavity: 1 ... | |

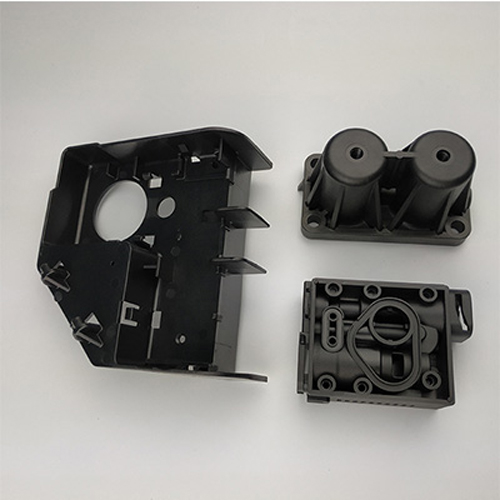

| Industrial Molding Parts | Industrial Molding Parts Industrial moulding parts are referred to the plastic parts of industrial precision molded products, we preferred to thin... | |

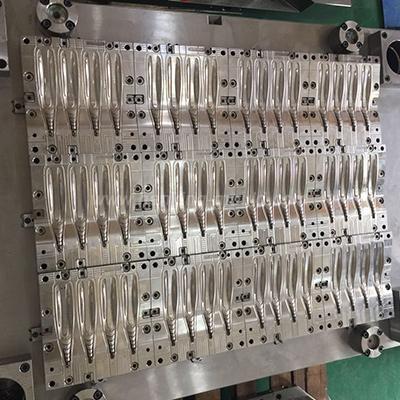

| Multi Cavity Mould | A multi-cavity mouldcan be understood, obviously referring to mold with multiple cavities. The multi-cavity mold comprises a multi-cavity of the sa... | |

| Electronic Molding Parts | Two Color Tooth Brush Injection Mould Plastic Parts Make plastic injection moldingand injection molding production for two color tooth brush inject... | |

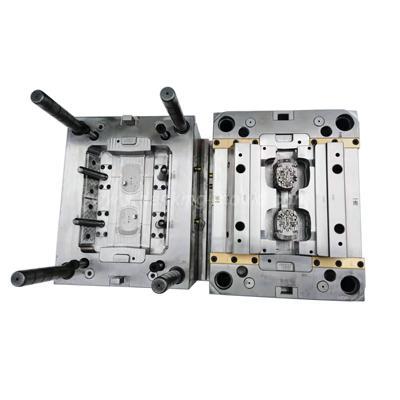

| Family Mould | Family Mold Injection Molding 491138 Mould Name: 1+1 Family Mould Part Material: PA6 GF30 Product Size: 78*35.6mm Product Description: Scharnier... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |