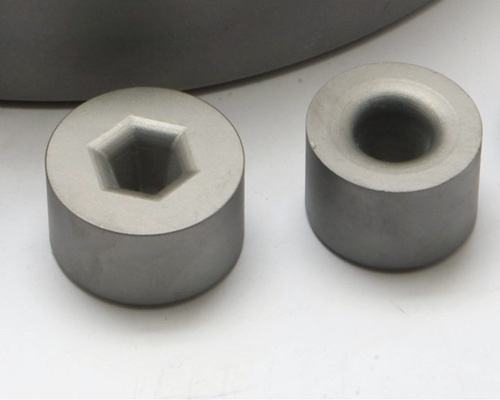

WIRE DRAWING DIE BLANK

According to the working properties, the structure of drawing die core can be divided into five sections: "entrance area, lubrication area, working area, sizing area and exit area"(See figure 1). The inner diameter profile of the drawing die is very important. It determines the tension required to compress the wire rod and affects the residual stress in the wire after drawing. The functions of each area of the die core are as follows: the entrance area is convenient for material threading and preventing the steel wire from scratching the drawing die from the entrance direction; the lubrication area is convenient for the steel wire to be brought into the lubricant; the working area is the main part of the die hole, and the deformation process of the steel wire is carried out here, that is, the original section is reduced to the required section size. When drawing metal with conical surface, the space occupied by the volume of metal in the working area is a circular table, which is called deformation area. The cone half angle α (also known as die half angle) in the working area is mainly used to determine the drawing force; the sizing area is used to obtain the exact size of the drawn steel wire; the outlet area is used to prevent the steel wire from surface scratching due to the instability of the steel wire exit.

Betalent carbide manufactures carbide drawing diescore blank as per drawing, tolerance of diameter and hole can be controlled to be very small, hole tolerance can be controlled to be +/-o.1mm, adding a polishing machining process you can get final ready grinding hole no need wire cutting or other allowance removing machining process, which can save lots of labor and machining cost. Betalent has moulds for some size of wire drawing blank, more and more size molds are in making, please contact sales person for the ready moulds list if you want to check to see if the wire drawing die size you need can be available from ready moulds or not.

Xiamen Betalent Carbide Co., Ltd isa professional carbide products inc, we provide die angle in wire drawing, pcd wire drawing dies, diamond wire drawing dies, tungsten carbide wire drawing dies, carbide tool, etc.Want to know wire drawing dies priceor more? Please contact us.

在线联系供应商

Other supplier products

| TAPER END MILL | The same as other end mills, there are flat end, corner radius end, and ball end. There are 2 flutes, 3 flutes, 4 flutes, and 6 flutes taper end m... | |

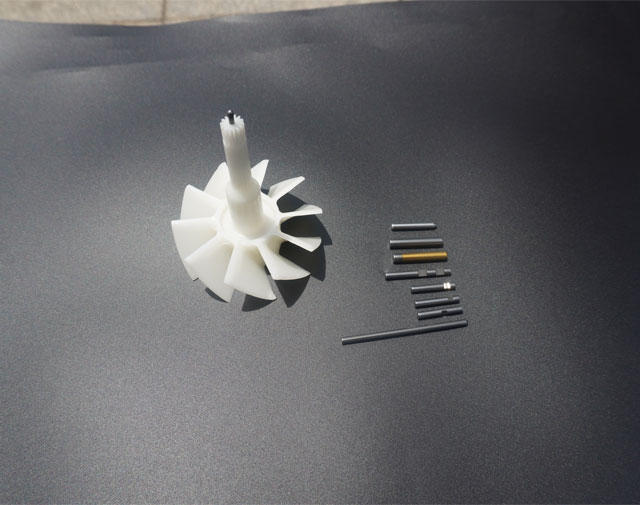

| WATER METER SHAFT | The shell is made of cast iron. After water comes out from the water inlet, it passes through the lower annular space of the shell, which is called... | |

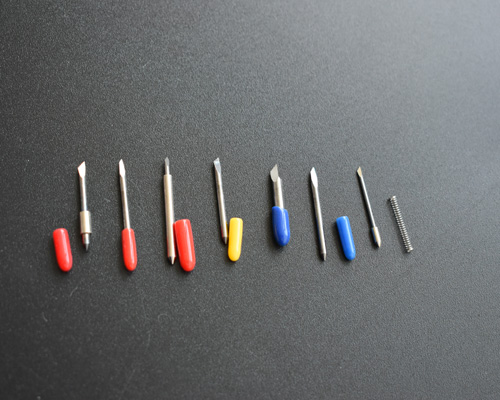

| PLOTTER BLADE | Vinyl cutter blade or named Vinyl plotter blade is installed to vinyl cutter machine Cutting materials: instant stickers, car stickers, back adhe... | |

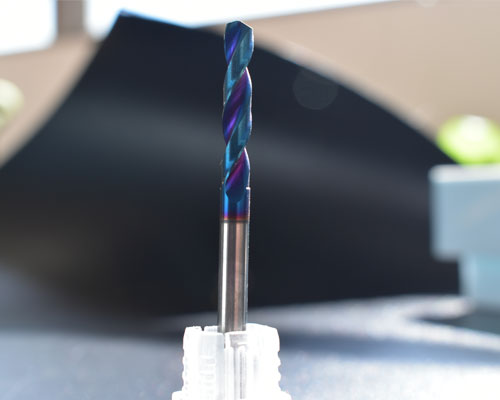

| COOLANT DRILL BITS | Betalent carbide COOLANT DRILL BITSapplication and advantages: through coolant drill bits, effectively reduce the chipping and maintain good wear... | |

| 2 FLUTE, 18MM FLAT CARBIDE END MILL, MILL CUTTER | 2 FLUTE, 18MM END MILL, MILL CUTTER Grain size Cutting dia. 18mm Grade BT55 Shank dia. 1... |