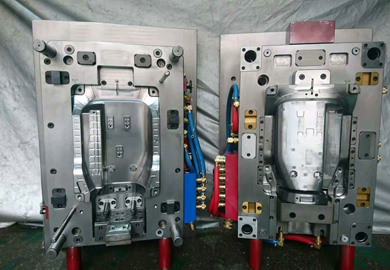

Insert Mould

Insert molding is an injection molding process used to encapsulate a component in a plastic part.

The insert custom plastic injection moldingprocess can be divided into two basic steps. First, the component is loaded into the mold before the molding process. Second, it takes the shape of the part and locks the component into the plastic as molten plastic is injected into the mold.

Features of Insert Mould

Insert molding is the process of inserting a part into a mold prior to the injection molding process. Since the insert injection molding process is the same, different materials are fed into the mould so as to produce different mould products. The main features of using insert mould by GM-TECH, a reliable injection moulding manufacturer, include:

Improved strength

A strong and reliable attachment point for inserts

Cost-effective compared with other inserting processes

No significant mold changes required

The Specification of Insert Mould

|

Part material |

ABS |

|

Cavity |

1 |

|

Mold accuracy |

+ / - 0.02 |

|

Mold steel |

H13 |

|

Moldbase steel |

|

|

Mold life |

100W |

|

Mold standard |

HASCO |

|

Mold structure |

3 slides |

|

Exporting country |

Germany |

|

Leadtime |

4 weeks |

|

Mold quality customer satisfaction |

98% |

|

FAI pass rate |

96% |

|

Project cooperation service customer satisfaction |

98% |

How does Insert Mould Work?

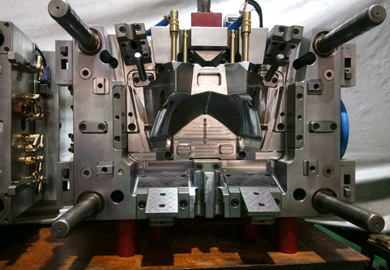

Insert molding is a powerful tool used to support the form and function of plastic injection molded parts. Insert molding refers to incorporating other parts, particularly metal parts, directly into the injection-molded product.

For instance, if there are metal inserts that we need to paste it to plastic. We need to place the metal inserts into the insert mold before injecting the plastic. The inserts will be surrounded by the plastic during the injection process, leaving the insert bonded firmly to the material after cooling and curing.

If you want to know more details of mold technology, please visit our website.

在线联系供应商

Other supplier products

| Automotive Part | As the foundation of the automotive industry, injection moulding automotive partsare necessary factors to support the sustainable and healthy devel... | |

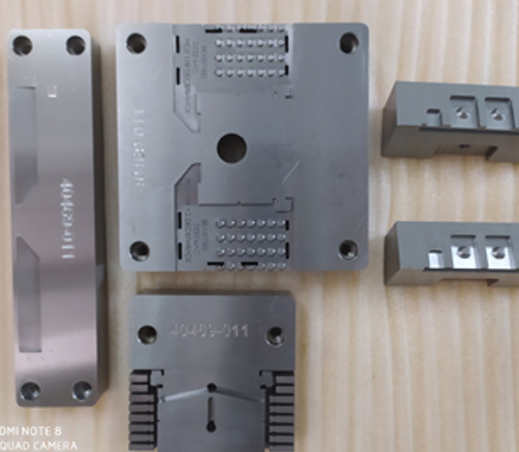

| Mould Component | Mould Componentare also a part of the mould.GM-TECH not only produces precision moulds but also provides customers with high-precision, low-cost mo... | |

| Injection Moulding Products | We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sale... | |

| Electronics Product Mould | Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics ... | |

| CNC Components | CNC Components Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. ... |

Same products

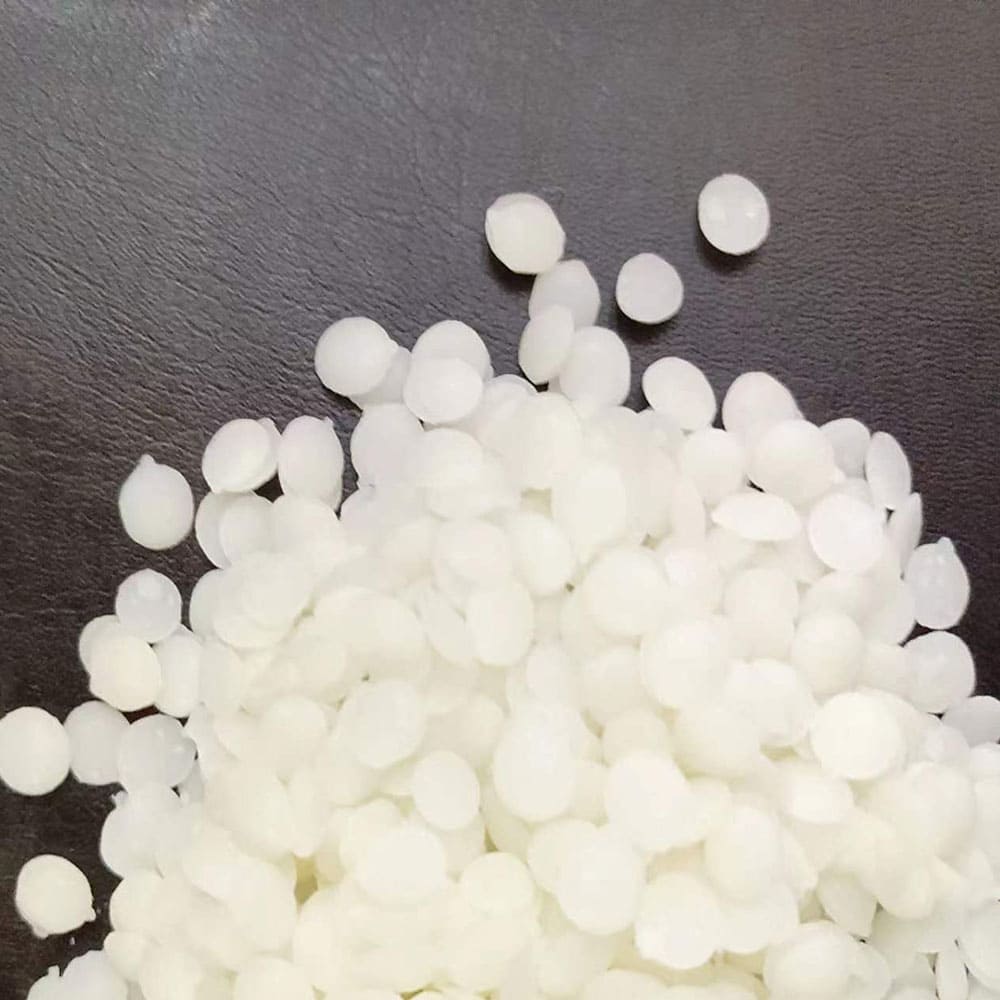

| Micronized wax for ink | 卖方: Syntop chemical Co.,Ltd. | The application of micronized wax in ink is mainly reflected in the following aspects: Improvemen... | |

| color fastness to gas fume tester | 卖方: G238BB Electronic Crockmeter | TRANSLATE with x English Arabic Hebrew Polish Bulgarian Hindi ... | |

| HALS Grease Pump HANSUNG Auto Lube System Original New | 卖方: 广东聚广恒自动化设备有限公司 | HALS KLUBER S88 PLUS 700G Grease | |

| Natural Slab yellow beeswax for candle | 卖方: Syntop chemical Co.,Ltd. | Nowadays, beeswax has begun to be used as green food additives, coatings, packaging, additives in... | |

| fogging test equipment | 卖方: G238BB Electronic Crockmeter | TRANSLATE with x English Arabic Hebrew Polish Bulgarian Hindi ... |