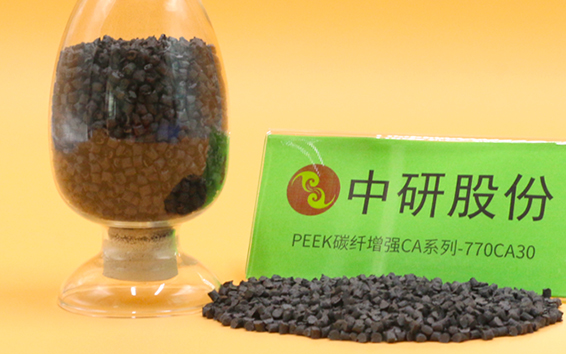

CA Series-770CA30 PEEK Carbon Fiber Reinforcement

CA Series-770CA30 carbon fiber filled peekreinforcement is widely used in automobile and aviation fields. It is widely used in automobile fuel pump and gearbox. It can help equipment reduce weight, reduce noise and increase the service life of wear-resistant parts, reduce or even avoid the use of lubricants.

Specification of CA Series-770CA30 PEEK Carbon Fiber Reinforcement

|

Material Properties |

Test Method |

Conditions |

Units |

770G |

|

Mechanical Data |

||||

|

Tensile Strength |

ISO 527 |

B reak,23℃ |

MPa |

- |

|

Y ield,23℃ |

MPa |

100 |

||

|

Tensile Elogation |

ISO 527 |

Break,23℃ |

% |

45 |

|

Flexural Strength |

ISO 178 |

Break,23℃ |

MPa |

- |

|

Y ield,23℃ |

MPa |

165 |

||

|

Fleoural Modulus |

ISO 178 |

23℃ |

Gpa |

|

|

Compressive Strength |

ISO 604 |

23℃ |

MPa |

125 |

|

Charpy Impact Strength |

ISO 179/leA |

Notched |

kJm-2 |

7 |

|

ISO 179/IU |

Unnotched |

kJm-2 |

- |

|

|

Izod Impact Strength |

ISO 180/A |

Notched |

kJm-2 |

|

|

ISO 180/U |

Unnotched |

kJm-2 |

- |

|

|

Mould Shrinkage |

ISO 294-4 |

Along flow |

% |

1 |

|

Across flow |

% |

|||

|

Thermal Data |

||||

|

Melting Point |

ISO 11357 |

℃ |

343 |

|

|

Glass Tansition (Tg) |

ISO 11357 |

Onset |

℃ |

143 |

|

Special Heat Capacity |

DSC |

23℃ |

kj kg-1℃-1 |

|

|

Coefficient of Thermal Expansion |

ISO 11359 |

Along flow below Tg |

ppm K-1 |

45 |

|

Along flow above Tg |

ppm K-1 |

120 |

||

|

Heat Deflecion Temperature |

ISO 75A-f |

℃ |

152 |

|

|

Thermal Conductivity |

ASTM C177 |

23℃ |

W m-1K-1 |

|

|

Flow |

||||

|

MeltIndex |

ISO 1133 |

380℃,5kg |

g10min-1 |

10 |

|

Miscellaneous |

||||

|

Density |

ISO 1186 |

Crystalline |

gcm-3 |

|

|

Amorphous |

gcm-3 |

|||

|

Shore D Hardness |

ISO 868 |

23℃ |

85 |

|

|

Water Absorption(3.2mm thick Tensile Bar) |

ISO 62-1 |

24h,23℃ |

% |

|

|

by immersion |

Equilib riu m,23℃ |

% |

||

|

Electrical Data |

||||

|

Dielectric Strength |

IEC 60243-1 |

2mm |

kV mm-1 |

23 |

|

Comparative Tracking Index |

IEC 60112 |

V |

150 |

|

|

Dielectric Constant |

IEC 60250 |

23℃,1kHz |

||

|

23℃,50kHz |

3 |

|||

|

Loss Tangent |

IEC 60250 |

23℃,1MHz |

||

|

Volume Resistivity |

IEC 60093 |

23℃,1V |

Ω cm |

10 16 |

|

275℃ |

Ω cm |

10 9 |

||

As a professional PEEK material supplier, ZYPEEK provides quality plastic PEEK materials wholesale with excellent properties. Our PEEK raw material line includes Grade G PEEK pure resin pellets, Grade PF PEEK pure resin fine powder, Grade R&D PEEK, etc. Contact ZYPEEK, your reliable PEEK material manufacturer, now!

在线联系供应商

Other supplier products

| Dental Tooth Materials PEEK R&D Series | Dental peek materialR&D Series has good wear resistance and high mechanical strength. It is mainly used in dentistry in medical field. Speci... | |

| CA Series-330CA30 PEEK Carbon Fiber Reinforcement | CA Series-330CA30 peek fccarbon fiber reinforcement is suitable for the production of bushing seals and other products, can be faster from the bear... | |

| Dental Tooth Materials PEEK R&D Series | Dental Tooth Materials PEEK Removable Denture R&D Series Dental peek material R&D Series has good wear resistance and high mechanical stren... | |

| PEEK in Wires & Cables | Polyetheretherketone PEEKhas outstanding heat aging properties, good flame retardancy, self-extinguishing, hydrolysis resistance, corrosion resista... | |

| Grade CA Carbon Fiber Reinforcement PEEK | PEEK-CA series reinforced plastics filled with carbon fiber, high elastic modulus, mechanical strength, creep resistance, wear resistance and dynam... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |