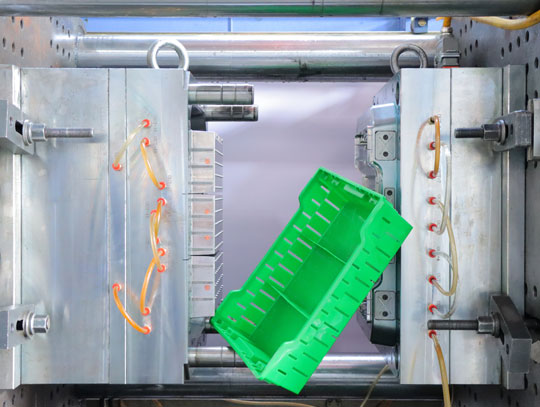

Injection Molding

Plastic Injection Molding

Plastic Injection Molding

Plastic injection mouldingis a method of making plastic products. The molten plastic is injected into the mold by pressure, and then cooled and molded to obtain various plastic parts. There are mechanical injection molding machines dedicated to injection molding. The most commonly used plastics are polyethylene, polypropylene, ABS, PA, polystyrene, etc.

Different Types of Injection Molding

Two Shot Molding

One category of injection molding that manufacture multi-color or multi-material components or parts with no extra injection or assembly process.

Insert Molding

One category of injection molding that allows custom components to be inserted into the plastic molded parts, such as threaded metal inserts.

Over Molding

One category of injection molding that integrate different materials, like rubber or silicone, into existing plastic parts, such as the soft elastomer material on the handle of a toothbrush.

Custom Injection Molding

When considering custom plastic injection molding china, it's of great importance to assess the complexity level of your project and let that dictate the customization level you need not only from the injection mold toolings themselves, but from front-to-back in working with molders.

Custom injection moulding depends on multiple scientific methods, analytical tools and injection moulding process technology in order to meet the precision and performance requirements for complex plastic components and applications. Although faster time to market is a definite consideration for custom injection molding projects, it isn't pursued at the cost of part design, injection moulding material selection, mold design and injection moulding process control. In order to achieve product design and end-use goal accurately, custom injection molders will use these key product development stages to inform choices about the appropriate injection moulding process step by step such as scientific molding, insert molding, multi-shot molding, overmolding, etc.

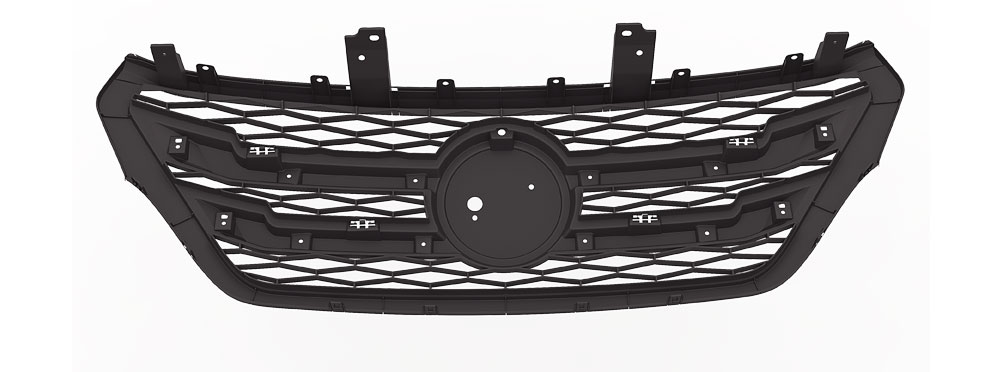

What Is Injection Moulding Used For?

Injection moulding application: Injection molding involves injecting hot, molten plastic material into a mold, which is then cooled and solidified to form the product. Injection moulding method is suitable for the mass production of complex products, especially in the field of plastic processing that occupies a large proportion.

Injection Molding Process Steps

Step 1: The tool closes and resin pellets are fed from a hopper into the barrel, which signifies the start of the injection moulding process steps.

Step 2: The screw rotates to auger the pellets forward toward the tool and resulting friction plus barrel heaters make pellets melt. The screw is pushed forward and injects the material at the force and speed necessary to properly fill the tool cavity.

Step 3: After the tool cavity is filled, the resin must be allowed to cool.

Step 4: When the injection moulding plastic part is cooling within the tool, the screw retracts and reloads with melt in order to prepare for the next injection.

Step 5: As long as the molded material reaches its ideal ejection temperature, the tool opens and the part is pushed out by the forward motion of the ejector rod and pins.

As one of injection molding accessories suppliers, we can offer sorts of industrial molding suppliesfor sale, if you have needs to buy plastic injection molding supplies, please contact us.

在线联系供应商

Other supplier products

| What is the Difference Between Overmolding and Insert Molding? | What Is the Difference between Insert Molding and Overmolding Plastic injection molding is one of the most widely used processes for manufacturi... | |

| Insert Molding | Insert molding is one category of injection molding that allows preformed parts or components, usually metal inserts, to be inserted into the plast... | |

| Injection Molding Materials | What material is used in injection moulding?Materials used in injection moulding generally include pla molding, nylon injection molding, polypropyl... | |

| Automotive Injection Molding | As a professional automotive plastic injection molding companiesKeyplast offers one-stop solutions for automotive industry. Many customers from aut... | |

| Plastic Injection Molding | What is plastic injection molding? Plastic Injection molding is a molding method that combines injection and molding. The advantages of plastic inj... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |