SPUTTERING TARGET BONDING

SPUTTERING TARGET BONDING

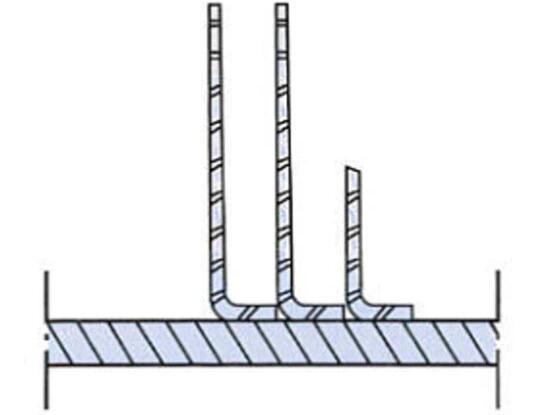

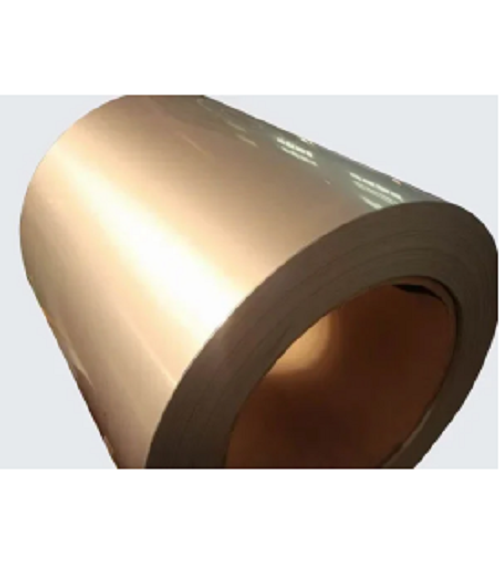

Sputtering target bondingis a process that involves attaching a sputtering target to a backing plate or a substrate holder. The bonding process is crucial in ensuring smooth and efficient sputtering operations. The target material is typically bonded to a metallic or ceramic backing plate, which is then mounted on the sputtering equipment for use in thin film deposition processes. The bonding process is performed using various methods, including mechanical clamping, soldering, brazing, diffusion bonding, and epoxy bonding. The choice of bonding method depends on the target material, substrate requirements, and process parameters. Proper bonding of the target material is crucial in ensuring high-quality and uniform deposition of thin films for a wide range of applications, including electronics, optics, and industrial coatings.

Types Of Sputtering Target Bonding

Molybdenum Target Bonding

ITO Target Bonding

Applications Of Sputtering Target Bonding In Various Industries

Semiconductor Industry: In the semiconductor industry, sputtering target bonding is used to deposit thin films of metals, insulators, and semiconductors onto substrates. This process is used for the fabrication of integrated circuits, metal interconnects, and metallization layers.

Display Industry: Sputtering target bonding is used in the production of LCD and OLED displays. The process is used for the deposition of transparent conductive layers such as Indium Tin Oxide (ITO) and Zinc oxide (ZnO).

Solar Industry: In the solar industry, sputtering target bonding is used for the deposition of thin film photovoltaic cells. The process is used for the deposition of materials such as Cadmium telluride (CdTe) and Copper Indium Gallium Selenide (CIGS).

Automotive Industry: Sputtering target bonding is used in the automotive industry for the deposition of coatings onto various components such as engine components, brake discs, and mirrors. The process is used for the deposition of materials such as Chromium (Cr), Titanium (Ti), and Tungsten (W).

Medical and Biotechnology Industry: Sputtering target bonding is used in the medical and biotechnology industry for the deposition of thin films onto medical devices such as implants and sensors. The process is used for the deposition of biocompatible materials such as Titanium Nitride (TiN) and Silicon Nitride (SiN).

Aerospace Industry: Sputtering target bonding is used in the aerospace industry for the production of thermal control coatings and sensors. The process is used for the deposition of materials such as Gold (Au), Silver (Ag), and Platinum (Pt).

Best Practices For Handling And Storing Bonded Sputtering Targets

Handling: Handle bonded sputtering targets with care to avoid damage or contamination. Always wear clean gloves when handling targets to avoid fingerprint marks or other oils.

Transportation: When transporting targets, make sure they are securely packaged and protected from impacts or drops. Avoid transporting targets in extreme temperature or humidity conditions.

Storage: Store bonded sputtering targets in a clean, dry environment, away from any moisture or contaminants. Metal targets should be kept in a dry, low-humidity area, while ceramic targets should be stored in a cool and dry location.

Sealing: Store bonded sputtering targets in a hermetically sealed container to prevent contamination from dust particles or other debris.

Reuse: If storing bonded sputtering targets for a long period, make sure to verify the bonding quality and integrity before reuse. Older targets may have reduced bonding strength and may require recoating or re-bonding.

Maintenance: Clean bonded sputtering targets regularly to avoid any buildup of debris or particulate matter. Use only appropriate cleaning solutions and avoid abrasive materials that could damage the bonding surface.

Discarding: Due to the hazardous materials used in manufacturing sputtering targets, dispose of bonded sputtering targets according to regulations and recommendations from the appropriate environmental agencies.

Improving Sputtering Target Bonding Reliability And Performance Through Process Optimization And Advanced Materials Development

Surface Preparation: Surface preparation is critical in ensuring strong bonding between the target and the backing plate. Target surfaces must be prepared by cleaning, polishing, and degreasing before the bonding process.

Adhesive Selection: The choice of adhesive material is crucial in ensuring strong bonding. Advanced adhesive materials such as high-temperature epoxies, nanocomposites, and metallic bonding alloys have been developed to improve bonding strength.

Optimizing Process Parameters: Process parameters such as temperature, pressure, and bonding time must be optimized to ensure strong bonding. These parameters can affect the bonding strength, quality, and uniformity of the deposited thin film.

Using Advanced Bonding Techniques: Advanced bonding techniques such as diffusion bonding and spark plasma sintering (SPS) have been developed to improve the bonding strength between target and backing plate.

Material Selection: The material properties of the target and backing plate must be selected carefully to ensure compatibility and strong bonding. Advanced materials such as fiber-reinforced composites and metal matrix composites have been developed to improve bonding strength.

Quality Control: Quality control measures such as visual inspection, surface analysis, and bonding strength testing must be performed at various stages to ensure that the bonding process has been successful.

Factors That Affect The Bonding Strength Of Sputtering Targets

Surface Preparation: The surface of the bonding materials must be prepared correctly before the bonding process. Proper cleaning, polishing, and degreasing of the surfaces can remove contaminants and improve bonding strength.

Adhesive Material: The adhesive material used for bonding plays a crucial role in the strength of the bond. The type of adhesive selected should be compatible with both the target and backing plate materials and have a high bonding strength.

Process Parameters: Bonding parameters such as temperature, pressure, and bonding time can affect the strength of the bond. Optimal bonding conditions must be determined through experimentation for each target and backing plate composition.

Target and Backing Plate Materials: The material properties of both the target and backing plate can affect the bonding strength. The coefficient of thermal expansion and melting point differences between the two materials can cause stress build-up and affect the bond's longevity.

Surface Roughness: The surface roughness of the bonding materials can affect the bond's strength. A surface that is too smooth can affect the adhesive's ability to establish a bond, while too rough of a surface could lead to an uneven bond with gaps.

Contamination: Any contaminants or grease on the surface of the target or backing plate could interfere with the bonding process. Thorough cleaning can prevent this.

Handling and Storage: Appropriate handling and storage of bonded targets are essential to maintain the bond's strength over time. Targets should be stored in clean, dry environments, and handled with care to avoid any damage to the bond.

If you want to know more kinds of industrial cooling system, please visit our website.

在线联系供应商

Other supplier products

| Evaporative Condenser | Evap condenser is a type of heat exchanger used to transfer heat from process fluids to the atmosphere. Unlike a direct air-cooled condenser, an ev... | |

| INDUSTRIAL EVAPORATIVE COOLING SYSTEM | Industrial evaporative cooling system is a cost-effective, energy-efficient approach to cooling large industrial spaces, production floors, and pub... | |

| Luoyang CBD, No.288 of Kaiyuan Avenue, Luoyang, Henan, China | Copper extractants are organic compounds used to selectively extract copper ions from ores and concentrates. They form chemical complexes with copp... | |

| Titanium Coil | Titanium Coil Titanium coilis a hollow, cylindrical structure made of high-strength, lightweight titanium metal, wound into a coil shape. It is us... | |

| NEW ELECTRONIC MATERIALS | New electronic materialsform the building blocks for the electronics industry. These materials are essential for the manufacture of electronic devi... |

Same products

| Monopotassium Phosphate | 卖方: Hebei Sanyuan Jiuqi Fertilizer Co., Ltd | Monopotassium phosphate,short as MKP, in NPK formulation: 00-52-34. It is a white crystal free fl... | |

| Titanium Slab | 卖方: Longhua Technology Group (Luoyang) Co., Ltd | Titanium Slab Pure titanium slabs are a fundamental product of titanium metal and titanium alloy... | |

| Titanium Coil | 卖方: Longhua Technology Group (Luoyang) Co., Ltd | Titanium Coil Titanium coilis a hollow, cylindrical structure made of high-strength, lightweight... | |

| SPUTTERING TARGET BONDING | 卖方: Longhua Technology Group (Luoyang) Co., Ltd | SPUTTERING TARGET BONDING Sputtering target bondingis a process that involves attaching a sputte... | |

| Pressure Vessel | 卖方: Longhua Technology Group (Luoyang) Co., Ltd | Pressure Vessel Pressure vessels can be categorized into refrigeration and chemical pressure ves... |