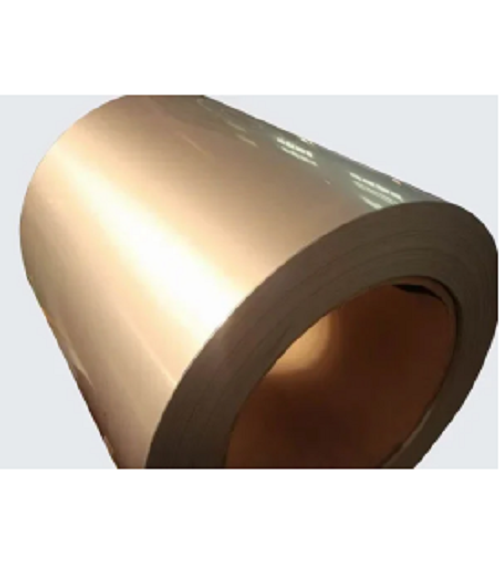

Titanium Coil

Titanium Coil

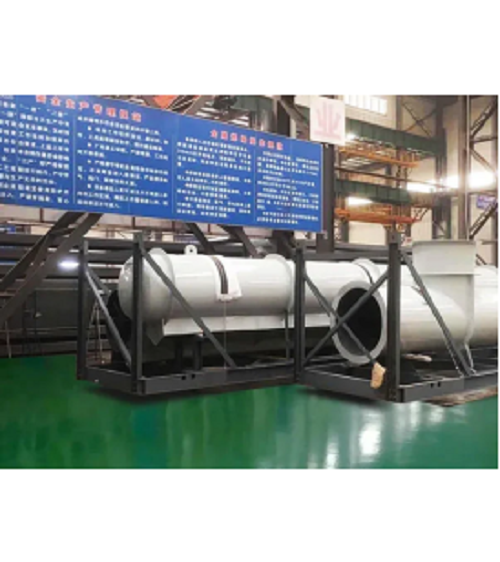

Titanium coilis a hollow, cylindrical structure made of high-strength, lightweight titanium metal, wound into a coil shape. It is used in various medical and industrial applications, such as surgical implants, chemical processing, power generation, and aerospace. Titanium coil has excellent corrosion resistance, biocompatibility, and low thermal expansion. Its unique properties make it an ideal material for high-temperature, high-stress applications where durability and longevity are critical.

Operating Principle of Titanium Coil

The operating principle of a titanium coil is based on its unique properties, which are characterized by excellent corrosion resistance, biocompatibility, and low thermal expansion. The properties of the titanium coil make it the ideal material for use in various applications across numerous industries.

In the medical field, titanium coil is used in surgical implants due to its biocompatibility, which eliminates any adverse reactions in the human body. Its low thermal expansion also ensures that the material does not cause any thermal damage during surgical procedures.

In industrial applications, titanium coil is used in chemical processing and power generation due to its excellent corrosion resistance. The material is resistant to chemical and thermal stresses, making it suitable for harsh environments. Furthermore, its low thermal expansion ensures that the material does not deform or warp when exposed to temperature changes.

In the aerospace industry, titanium coil is used to manufacture aircraft components such as engine blades and structural components due to its strength, durability, and lightweight properties. Its high strength-to-weight ratio helps reduce aircraft weight, enhancing fuel efficiency and increasing payload capacity.

In conclusion, the operating principle of titanium coil is based on its unique properties and how they can be tailored to suit various industrial needs. Its applications range from aerospace, medical, industrial, and beyond due to its exceptional properties of corrosion resistance, biocompatibility, and low thermal expansion.

What Are the Benefits of Using Titanium Coil?

The benefits of using titanium coil are numerous and have led to its increasing use across various industries. Some of the key benefits include:

Corrosion resistance: Titanium coil is highly resistant to corrosion, making it an ideal material for use in harsh environments such as chemical processing.

Biocompatibility: Titanium coil is biocompatible, meaning it is not rejected by the human body, making it ideal for use in medical applications such as surgical implants.

Low thermal expansion: Titanium coil has a low coefficient of thermal expansion, meaning it does not expand or contract significantly with changes in temperature. This property makes it ideal for use in high-temperature applications.

High strength-to-weight ratio: Titanium coil has a high strength-to-weight ratio, making it a suitable choice for applications that require strength without excessive weight.

Environmental sustainability: Titanium coil is recyclable, making it an environmentally sustainable material.

Durability: Titanium coil is highly durable and has a long lifespan, ensuring its longevity and longevity of the product.

Cost-effectiveness: Although titanium coil is expensive compared to other materials, its long lifespan and durability make it cost-effective in the long run.

In conclusion, the benefits of using titanium coil are significant, making it a highly valued material across various industries such as aerospace, medical, chemical processing, and power generation, among others.

As one of cooling tower manufacturers, we will do our best to meet all the needs of customers.

在线联系供应商

Other supplier products

| ITO Target | ITO targetis made up of a combination of indium oxide and tin oxide and serves as a crucial component in the production of ITO film. This film hold... | |

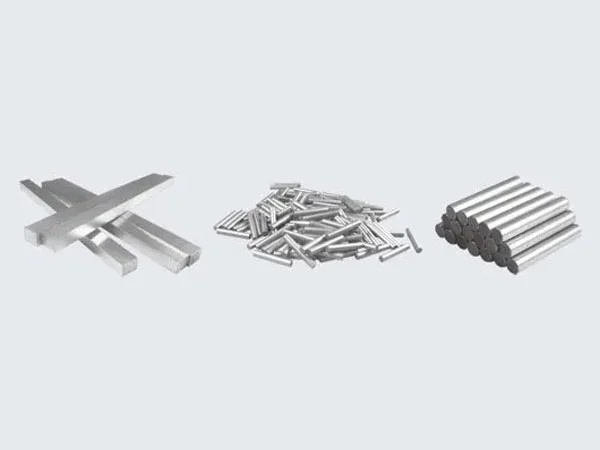

| Molybdenum Bar/Rod | Molybdenum round barexhibits several advantages, including high melting and boiling points, good high-temperature strength, resistance to friction ... | |

| Titanium Coil | Titanium Coil Titanium coilis a hollow, cylindrical structure made of high-strength, lightweight titanium metal, wound into a coil shape. It is us... | |

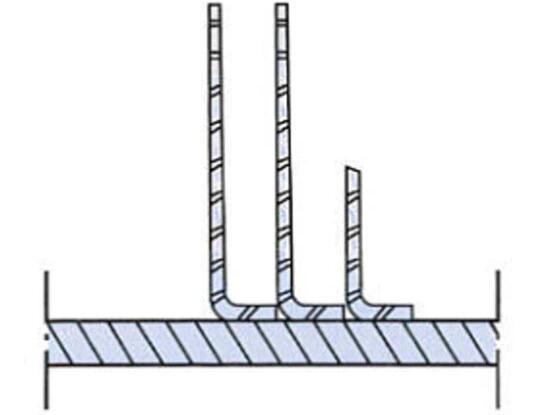

| Molybdenum Screw. | Molybdenum screwis a fastener made of molybdenum, a refractory metal with excellent strength, corrosion resistance, and thermal stability. Molybden... | |

| Evaporative Condenser | Evap condenser is a type of heat exchanger used to transfer heat from process fluids to the atmosphere. Unlike a direct air-cooled condenser, an ev... |

Same products

| Monopotassium Phosphate | 卖方: Hebei Sanyuan Jiuqi Fertilizer Co., Ltd | Monopotassium phosphate,short as MKP, in NPK formulation: 00-52-34. It is a white crystal free fl... | |

| Titanium Slab | 卖方: Longhua Technology Group (Luoyang) Co., Ltd | Titanium Slab Pure titanium slabs are a fundamental product of titanium metal and titanium alloy... | |

| Titanium Coil | 卖方: Longhua Technology Group (Luoyang) Co., Ltd | Titanium Coil Titanium coilis a hollow, cylindrical structure made of high-strength, lightweight... | |

| SPUTTERING TARGET BONDING | 卖方: Longhua Technology Group (Luoyang) Co., Ltd | SPUTTERING TARGET BONDING Sputtering target bondingis a process that involves attaching a sputte... | |

| Pressure Vessel | 卖方: Longhua Technology Group (Luoyang) Co., Ltd | Pressure Vessel Pressure vessels can be categorized into refrigeration and chemical pressure ves... |