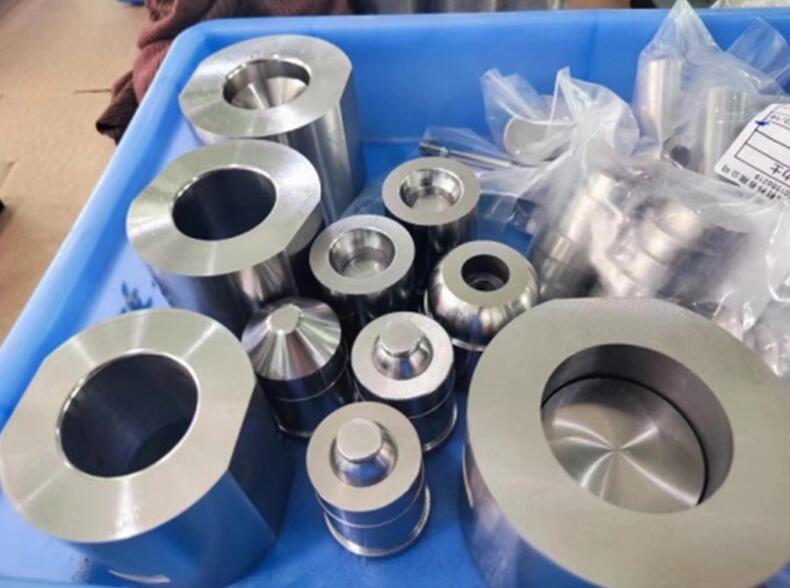

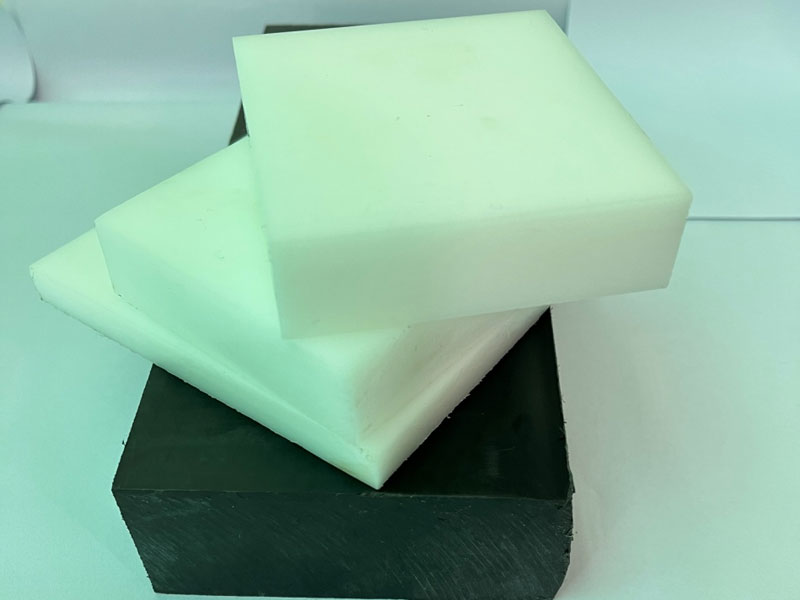

PEEK Non-standard Parts

PEEKprecision machiningmaterial is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mechanical properties, in many special areas can replace metals, ceramics and other traditional materials, in reducing the quality, improving the performance of outstanding contribution to become one of today's most popular high-performance engineering plastics. PEEK material's high-temperature thermal performance is very outstanding, can be used for a long time at 260 ℃, instantaneous use Temperature of up to 300 ℃; its rigidity, dimensional stability, the coefficient of linear expansion is small, close to the metal aluminum materials.

What are The Advantages of China PEEKCNCMachining?

◆ High-temperature resistance

The United States UL certification long-term use temperature of 260 ℃.

◆ Self-lubricating

With a low coefficient of friction, it can work without oil lubrication and can work in oil, water, weak acid and alkali medium for a long time.

◆ High strength

It has the best mechanical strength among plastics. It also has high rigidity and surface hardness.

◆ Corrosion resistance

It is insoluble in common solvents and has good corrosion resistance to various organic and inorganic chemical reagents.

◆ Abrasion resistance

It has excellent wear resistance in many extremely harsh environments such as high temperatures, high load and strong corrosion.

◆ Hydrolysis resistance

◆ Easy processing

Parts can be processed directly by an injection molding process. Post-processing such as turning, milling, drilling, tapping and ultrasonic welding can be performed.

◆ Flame retardant

◆ Low smoke and non-toxic

◆ Radiation resistance

It has excellent resistance to high dose γ-ray radiation, and the mechanical properties can be retained intact, so it can be used as radiation-resistant parts in nuclear equipment.

Electrical performance

◆ Dimensional stability

Features of PEEK Non-standard Parts

As one of peek cnc machining factories, we will do our best to meet all the needs of customers.

We are a professional precision machining companyfocusing on OEM & ODM customized services. Specializing in precision quality machining, non-standard spare part processing, metal stamping and metal prototyping.

在线联系供应商

Other supplier products

| Precision Spare Parts | We manufacture high-precision parts for customers around the world for virtually all advanced technology manufacturing industries, such as communic... | |

| Carbide Mold Components | Carbide Components We are very capable of customizing punches and dies to produce precision tungsten punches, bushings, ejectors, and die componen... | |

| Non-standard Parts | Non-standard Parts Standard parts are parts produced in accordance with national standards (GB), industry standards, or foreign standards, mainly f... | |

| CNC Machining Material | Metal Material Machining Aluminum Alloys Aluminum alloy material is divided into: 6061 mainly contains magnesium and silicon elements, suitable... | |

| Custom Precision Machined Parts | As the leading supplier of custom precision parts, we have 10 years of experience in custom fabrication services which include CNC machining servic... |

Same products

| Oxytocin CAS 50-56-6 Wholesale & Bulk | 卖方: Wuhan Fortuna Chemical Co.,Ltd. | Oxytocin is absorbed by the oral mucosa and selectively acts on the smooth muscles of the uterus,... | |

| Omeprazole CAS 73590-58-6 Wholesale & Bulk | 卖方: Wuhan Fortuna Chemical Co.,Ltd. | omeprazole is a proton pump inhibitor used to treat diseases such as peptic ulcer and gastroesoph... | |

| PEEK Non-standard Parts | 卖方: SHEN ZHEN HUIHUAN TECHNOLOGY CO,.LTD | PEEKprecision machiningmaterial is a new type of semi-crystalline aromatic plastic engineering pl... | |

| Pot Magnet with Mounting Hole | 卖方: Weizhong Magnetics Co.,Ltd | They are round magnets with hole in centerand they can be also called: pot magnet with borehole, ... | |

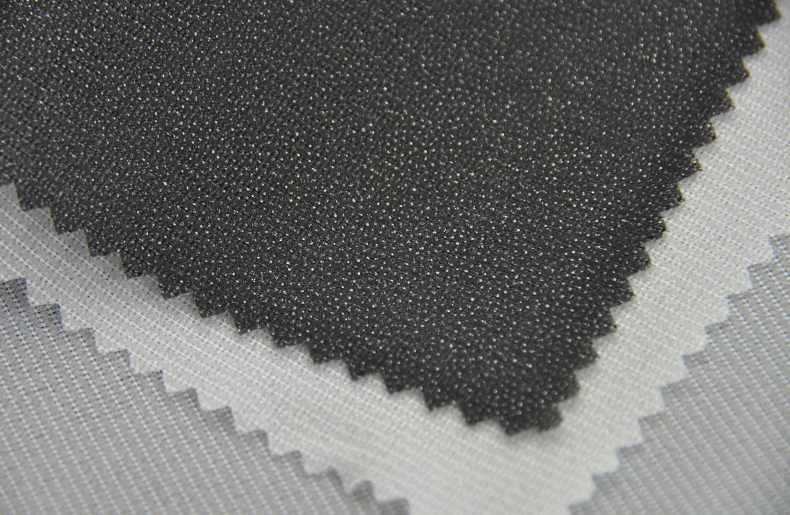

| Woven Interlining Polyester Fabric Lining For Fabric Textile | 卖方: Hangzhou RAINBOW Interlining Co.,Ltd | 1: This product uses the international advanced double/point coating process, with good dry clean... |