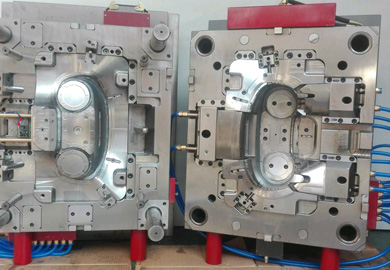

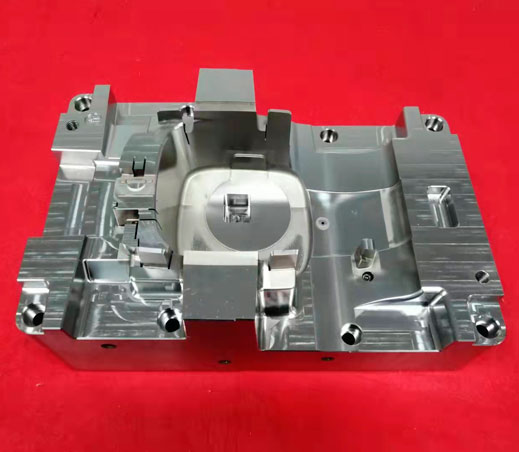

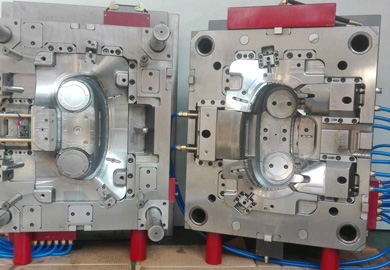

Plastic Injection Mould

GM-TECH is mainly engaged in the production of high-precision injection mould production plants. And the production of precision injection moulds is very widely used, including products such as automotive plastic parts, medical plastic parts, electronic plastic products, toy plastic products, industrial products, etc. In the early stage, we have won the trust and cooperation of customers with decades of professional mould design experience. In the later stage, we will win the long-term trust and cooperation of customers with reliable and stable mould quality!

Plastic Injection Mould Features

All the injection molds and molding parts that we made are exported to abroad such as,USA, Europe, Japan, Singapore, India and other countries. Molds vary from 50kg to 10 tons ,Including automotive product molds, electronic product molds, industrial product molds, home appliance molds, medical product molds and so on.

The leadtime for mold manufacturing generally takes 4-8 weeks, depending on the ease of the mold.

GM-TECH mainly produces and designs high-precision and high-quality moulds. We are good at the fields of automobile product mould, electronic product mould, household appliance mould, medical product mould, insert mould, two-color mould, multi hole mould, thread mould, gear mould, etc.

Plastic Injection Mould FAQs

What are your common mold steel?What are your common mold steel?

Generally, we use steel materials required by customers, such as 1.1343, H-13, S136, NAK80, P20 and so on. And we will provide steel certification to customers.

How long is the delivery time for mold processing?How long is the delivery time for mold processing?

Specific to see the difficulty of mold, generally 2-8 weeks

Is your company familiar with export mould standard?Is your company familiar with export mould standard?

Yes, we are very familiar with DME, HASCO and Mishmi standards.

How do you guarantee the quality of the mould?How do you guarantee the quality of the mould?

Mold design: when the design is completed, our engineers will meet to review the mold. Mold processing: CMM inspection will be carried out for each machining step (electrode, CNC,) of parts.

GM-TECH is a professional China injection mould factory, we provide injection mold service china, rapid prototyping plastic injection molding, plastic injection mold and molding, high quality injection moldand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Plastic Injection Mould | GM-TECH is mainly engaged in the production of high-precision injection mould production plants. And the production of precision injection moulds i... | |

| Insert Mould | Insert molding is a precision injection moldingprocess used to encapsulate a component in a plastic part. The insert plastic injection molding p... | |

| Vacuum Moulding | GM-TECH, a plastic injection company, has been manufacturing tools for injection molding of plastics for various industries for more than 10 years.... | |

| Mould Component | Mould Component Mould Componentsare also a part of the mould. GM-TECH not only produces precision moulds but also provides customers with high-pre... | |

| 2K Mould | 2k injection mouldingis a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines t... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |