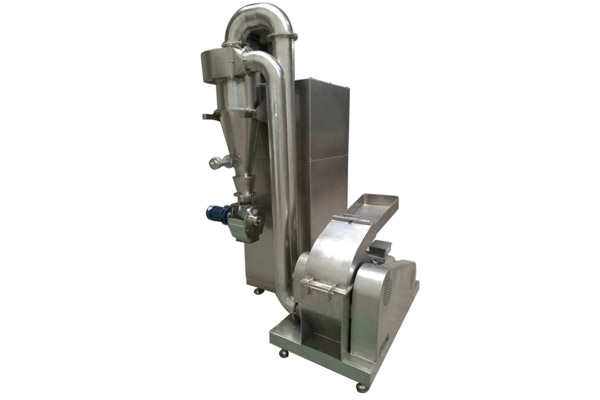

Garri Fryer(Cassava Garri Fryer)

Features of Garri Fryer(Cassava Garri Fryer)

Roasting be done mechanically using an automated garri fryer made of stainless

steel material and with electricity, natural gas, firewood or charcoal as the heat source. The finished product (Garri) is usually recognized from the color change from white to cream (for non-palm oil fortified Garri) and crispy hand feel of the grains/particles.

Processing Capacity: 100-300kgs/hour

Application Scope: Garri frying or roasting

Product Name Introduction: cassava garri fryer, garri frying machine, gari fryer, gari frying machine, Garri fryer, cassava fryer machine, cassava frying machine, cassava roasting machine, cassava drying machine for cassava garri processing

Product Structure of garri frying machine

① Electric: A large heated area, temperature-controlled, heat evenly.

② Gas: Easy to use, fast heating, meet some of the demand for high temperature, unrestricted factory voltage.

③ Coal: Original heat source used for local traditional Garri processing.

All parts of the frame body and all food contact areas are 304 stainless steel and polished, consistent with "People's Republic of China Food Sanitation Law" requirements, with beautiful appearance, reasonable design, compact structure, easy installation, simple operation, easy maintenance.

echnical Parameters of Cassava Garri Fryer Machine

|

Modelno. |

GD-EF-1200 (Electric heating) |

GD-GF-1200 (Gasheating) |

|

Machinematerial |

Stainlesssteel |

Stainlesssteel |

|

Capacity |

150-200KG/H |

150-200KG/H |

|

Power |

18KW |

|

|

Voltage |

380V/50Hz3Phase |

380V/50Hz3Phase |

|

Rotatespeed |

29R/Min |

29R/Min |

|

Heattransferarea |

2m2 |

2m2 |

|

Operatingtemperature |

150-180℃ |

150-180℃ |

|

The innerdiameterofthe pot |

1200mm |

1200mm |

|

Innerdepthofthe pot |

400mm |

400mm |

|

The innervolumeofpot |

400L |

400L |

|

Weight |

750KG |

750KG |

|

Dimension(L×W×H)(mm) |

1500×1500×1250 |

1660×1400×1200 |

If you want to know garri processing machine cost, please contact us.

在线联系供应商

Other supplier products

| Garri Fryer(Cassava Garri Fryer) | Features of Garri Fryer(Cassava Garri Fryer) Roasting be done mechanically using an automated garri fryer made of stainless steel material and with... | |

| Cassava Flour Machine | Cassava Flour Production Process Description and Flowchart: Cassava flour is also called cassava whole flour, which is the fine powder, a little y... | |

| Garri Processing Machinery | Cassava Garri(Gari) Process Description and Flowchart: Garri is a fermented and gelatinized dry coarse flour, very popular in West Africa and a sta... | |

| Cassava Flour Milling Machine | Features of Cassava Flour Milling Machine Processing Capacity: 400-500kgs/hour Application Scope: Milling the coarse powder into fine powder Produ... | |

| Dewatering and Drying System | The section of dewatering and drying has come to final steps of cassava processing, the vacuum dehydrator can remove as much moisture as possible a... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |