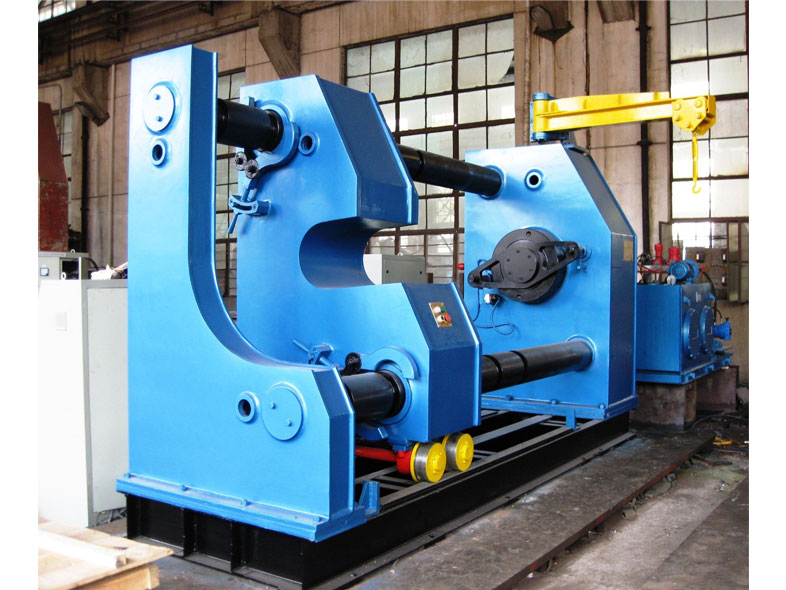

Plate Bending Machine

The plate bending machine chinais forging equipment used to bend metal plates. It is dedicated to the forming and bending work of metal plates. This roll plate bending machine can pre-bend and roll various cylindrical and arc-shaped parts with the help of auxiliary equipment. Rolling of cone-shaped cylinders can be carried out. It is one of the key metal fabrication equipment in the boiler, shipbuilding, petrochemical, metal structure, cement machinery, chemical machinery, machinery manufacturing, and maintenance departments. EZHONG has high quality used steel plate roller for sale.

EZHONG as one of the leading plate rolling machine suppliershas accumulated rich experience in manufacturing heavy-duty three-roller bending machines, full hydraulic three-roller bending machines, CNC four-roller bending machines, and other bending roller machines; China's largest bending machine EZW11X-300*3500 hydraulic three-roller bending machine is manufactured by EZHONG. The maximum pressing force of the CNC plate bending machine is 7800T, which is second to the 3 roll bending machine with a pressing force of 8000T from Switzerland HAEUSLER. And

As a bending machine factory, EZHONG also provides low-cost and high-quality second hand plate rolling machines.

Plate Bending Machine Working Principle

The purpose of the plate rolling machine is to bend the plates with different characteristics according to the production capacity.

The production process of the plate rolling machine in EZHONG plate rolling machine China is to operate the machine from the control panel (equipped with all control equipment and indicator lights) under the control of the operator.

The system of the rolls bending machine must be stable. If something happens to the metal fabrication equipment, a big problem will occur after a few days, so how to choose a stable system? You need to check the product history and customer evaluation, and also need to see the production experience of the plate rolling machine manufacturers if there are technical elites.

The material and processing technology of work plate rolls require quenching and tempering to increase the surface hardness; structural parts need to eliminate stress, and high-precision processing equipment can ensure assembly accuracy; bearings are also crucial.

The maximum working capacity of the three-roller plate bending machine depends on the four main parameters of the maximum coil thickness (pre-bending thickness), the maximum coil width, the coil material, and the minimum diameter of the coil in the largest specification. These four-parameter variables influence each other in work. The conversion relationship between the rolling bending machine, that is, the conversion relationship of the machine's working capacity, is provided to the user in the random manual so that the user can use and select the roll plate bending machine more reasonably.

How do you use a plate roll bending machine??

Sheet bending roller machineoperation: standard use process.

This machine is a three-roller plate bending machine with pre-bending and variable center distance. This model is different from the traditional model. Because the two lower steel plate rollers can move horizontally at the same time or completely independently, adjust the pitch between the steel plate rollers; the upper plate rollers can move up and down. Due to the above characteristics, the bending roll machine and campus capabilities have been greatly improved, and the coiling thickness has also been greatly increased.

The reverse movement of the upper and lower steel plate rollers should be braked first and then reverse operation.

The rebound is more pronounced during cold rolling, and a certain amount of overwinding must be applied. After the required amount of overwinding is reached, it should be rolled back down to this curvature several times. High-strength steel has a large rebound. In order to reduce the rebound, it is best to perform an annealing treatment before the final forming.

After the rolling bending machine workpiece is rolled, the upper steel plate roller should be raised to more than 300mm on the line and the upper steel plate roller is in a horizontal state before unloading the workpiece.

More types of roll forming machine second handfor sale, please visit our website.

在线联系供应商

Other supplier products

| Horizontal Axle Press | The horizontal wheel axle press machine is the installation equipment for the rolling bearing of the railway vehicle system. Its main purpose is to... | |

| Profile Bending Machine | The hydraulic profile bending machineis special high-efficiency processing equipment for the bending of various profiles such as angle steel, chann... | |

| Profile Bending Machine | The profile bending machine is special high-efficiency processing equipment for the bending of various profiles such as angle steel, channel steel,... | |

| Ship Plate Bending Machine | EZHONGhas accumulated rich experience in the manufacturing of plate bending rolling machines such as large-scale horizontal 3 roll bending machine,... | |

| Horizontal Axle Press Machine | The horizontal press machineis the installation equipment for the rolling bearing of the railway vehicle system. Its main purpose is to press the r... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |