Inline X-Ray Inspection Machine

Inline X-Ray Inspection Machine

In the inspection process of electronic components, the pcb x ray inspection equipmentcan be directly connected to the SMT production line for high-capacity automatic inline full inspection, it can be used offline with unloader and loader. The x ray inspection machine priceis very reasonable. Fully automatic judgment and inspection are carried out for the characteristic area of the circuit board or the designated device. The automated inline x ray machine for electronicssupports fully automatic inline inspection of IC, BGA semiconductor devices, SMT and PTU packages, sensors and other fields.

Seamark Inline PCB SMTXRay InspectionMachine

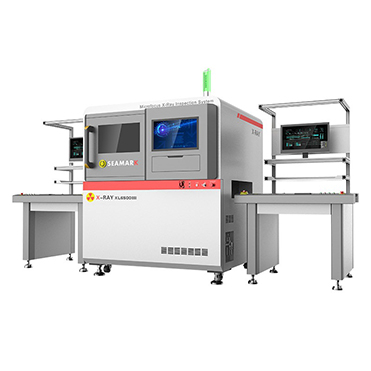

XL6500 Inline X-Ray Inspection Machine

XL6500 is an smt x ray machinefor electronic components. It can be directly connected to the SMT production line, or it can be used offline with the loading and unloading conveyors.

How does an Inline X-Ray Inspection Machine Work?

The pcb x ray inspection systemsuses high-voltage accelerated electrons to release x-rays that penetrate the sample and leave an image. The technician observes the relevant details of the sample through the brightness of the image.

What Is X-Ray Printed Circuit Board (PCB) Inspection machine?

Across different fields, from aerospace to aquatic to clinical manufacturing, x-ray PCB inspection machine is used to discover covert flaws in solders and various other manufacturing errors, which are unseen to ordinary optical inspections. Utilizing x-rays to determine errors, minor or significant, x-ray PCB inspection equipment does not damage the board under inspection.

The aspects that make PCB inspection a challenging affair consist of:

Surface Mount Technology

The Surface Mount technology has actually led to smaller packages as well as leads. These, consequently, make PCBs denser, with numerous parts concealed between the layers.

Size of the components

Miniaturization of motherboard elements is currently a pattern in electronics production. Currently, there's an excellent need for denser boards, which has exerted pressure on the manufacture of PCB components.

Placement of Components

There's a wonderful demand for smaller as well as layered equipment to save on room as well as make the best use of capabilities. As a result, lots of components as well as solder joints are being placed within the internal layers of electronic devices.

These complex needs, as well as designs, make it hard for common inspection techniques such as ultrasonic, optical, and thermal imaging to supply detailed fault-finding images. To get rid of these difficulties, an X-ray for PCB inspection is utilized.

Benefits of X-Ray for PCB Inspection

Quick responses at the beginning of product development allows the makers to take restorative steps to improve quality and also motivate a favorable brand name.

Designers will certainly have the opportunity not to improve defective components, minimizing unneeded expenses.

The x-ray makes it possible for inspectors to recognize a series of possible problems on the printed motherboard and recommend specific corrective actions.

Now the price of x ray inspection machine for saleis reasonable, anything you need, please contact us.

Shenzhen ZhuomaoTechnology Co., Ltd has been focusing on intelligent soldering and intelligent inspection equipment for 16 years, and has specialized in providing advanced intelligent BGA Rework Station, X-Ray Inspection Machine, X-Ray Counter Machine, 3D X-Ray Inspection Machine, Automatic Tin Removal Equipment, Automatic Reballing Machine, Laser Soldering Equipment, non-standard automation equipment, and other overall solutions for electronic manufacturing, 3C products, industrial precision castings, semiconductors, and other industries.

在线联系供应商

Other supplier products

| Offline X-Ray Inspection Machine | Seamark's 2D industrial x ray inspection equipmentadopts a closed microfocus X-ray tube with voltage 90KV, 110KV,130KV, which meet different produc... | |

| XC1000 Offline Reel Counter | XC1100is a micro-focus X-ray full-automatic counting machine. It uses X-Ray perspective principle and independently developed algorithm software... | |

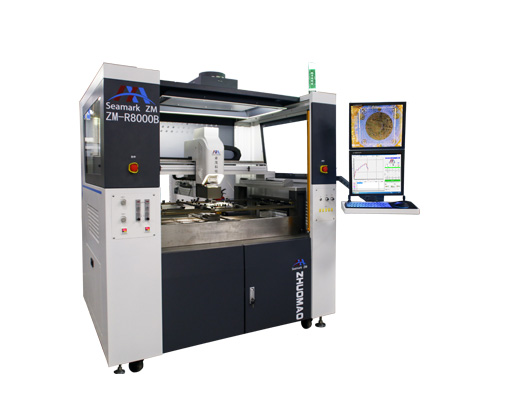

| ZM-R8000B Large Precision Rework Station | R8000BSurface Mount/SMD BGA rework station is a large-scale precision rework station. This BGA rework system has a self-tuning temperature curve, l... | |

| ZM-R7220A Infrared Soldering Station | ZMR7220Ainfrared SMD rework stationis an intelligent infrared soldering station with real-time temperature monitoring, optical alignment system, ra... | |

| ZM-R720A LED/Micro Component Rework Station | ZM R720Amicro/mini BGA rework station is a precision optical intelligent LED reworkstation suitable for the rework of precision microdevices. This ... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |