2k Injection Molding

2K is well known as 2 shot injection molding or two colour injection moulding, consists of two different plastics or two different colors of one plastics into an end product by means of one injection molding process.

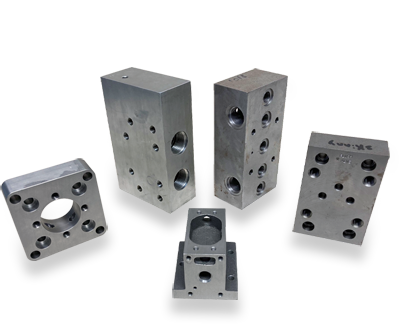

Premium is an industrial machining inc that has manufactured parts using the 2K injection moulding process for more than 20 years. The 2k injection molding process enables several functions to be integrated into an injection molded part. Due to the chemical bond between the different materials, excellent adhesion is achieved, without the thermoplastic part requiring chemical pre-treatment. two colour/ 2K injection moulding component technology is also ideal for parts with large batches.

How Does 2K Injection MoldingWork?

2k moulding, sometimes know as double injection, two color injection molding, or 2 shot molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials into the multi-chambered mold.

2K injection moulding perform in one machine which is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The 2k plastic injection mouldingis then rotated automatically and another type of plastic is injected from a second nozzle into the mold.

Two color injection moldingoptimizes co-polymerization of hard and soft materials to create a perfect bond with production and feature advantages for a single part. Almost all industries can use two colour injection mouldingfor a variety of product designs. The 2k injection also allows for moulding using clear plastics, colored graphics, and stylish finishes which improves customer's product functionality and marketplace value.

Advantages Of 2K Injection Molding

No secondary processing and assembly steps

Excellent adhesion to the plastic part

Low handling

Quick cycle times

High degree of automation

Stable production processes

Economical cost

As one of the professional injection mold components suppliers, Premium has advanced machines that take 2K injection molding/two colour injection moulding.

The 2k injection moulding allows us to integrate multiple properties into one product: for instance, layered products, combinations of hard and soft plastic for making different color combinations.

The technology 2K injection molding makes it possible to produce a complete product so that this part does not need further secondary processing and assembly steps. That means gains in the quick cycle time, a constant process, a higher degree of efficiency and the avoidance of manual operation, you can save cost also save considerably on costs with two colour injection moulding.

2K Injection Molding Parameters

|

Plastic Material |

PP, PP+20% GF, PA6, PLA, AS, ABS, PE, PC, PVC, POM, PET, PS, TPE/TPR etc |

|

Mold Material |

718H, P20, NAK80, S316H, SKD61, etc. 20~60 HRC |

|

Mold Base |

HASCO, DME, LKM, JLS standard |

|

Mold Runner |

Cold runner, hot runner |

|

Mold Cold Runner |

Point way, side way, follow way, direct gate way, etc. |

|

Mold Hot Treatment |

Nitridation, tempering, etc. |

|

Mold Surface |

texture, EDM, high gloss polishing |

|

Mold Cooling System |

water cooling or Beryllium bronze cooling, etc. |

|

Lead time |

25-60 days |

Two Color Injection Molding Technology Processes

Two Color Injection Molding Technology Types

The two color injection molding technology has three types according to the structure classification. They are core rotation, core retreat, push plate rotation.

Two Color Injection Molding Technology Features

First of all, the two color injection molding technology needs to match the injection molding machine. 2k mould has more than a rotating mechanism or up and down sliding mechanism.

Secondly, there is a difference in the 2k injection moulding former model, and then the core is consistent. Two color injection molding technology should pay attention to the application of cylinder or other power.

Finally, the precision of the two colour injection moulding technology is high.

Two Color Injection Molding Technology Design Features

The two shapes of the mother mold are different, forming one product respectively. While the two shapes of the male mold are exactly the same.

The front and back of the two color injection molding products must match after rotating 180°to the center.

Premiumis a reliable precision components manufacturers, we provide precision machining and manufacturing, plastic injection molding, injection molded parts, die castingand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| CNC Turning Service | Our CNC turning service produces most cylindrical and conical shaped parts on the CNC lathes. CNC Turning is a machining process in which material ... | |

| Alu Extrusion | Alu Extrusion includes bending, piercing, notching and welding. Premium's experience experts can also help with standard, custom shapes, and design... | |

| Sheet Metal Processing | Premium machining service is professional in a wide range of sheet metal parts, in addition to systems for stamping, bending, punching, laser proce... | |

| Sheet Metal Stamping | Premium provide low cost and high speed sheet metal stamping processing which is a manufacturing process that can produce a high volume parts and c... | |

| Aerospace CNC Machining | Premium is the expert in aerospace precision machining, especially good at handle the high precision components even with very complex geometries, ... |

Same products

| FOTON 12 TONS HOOKLIFT TRUCK | 卖方: Hubei Yuantai Special Automobile Co., Ltd | The hooklift garbage truckis a special sanitation vehicle modified on the basis of Foton brand ch... | |

| China High Quality OEM CNC Machining steel metal parts | 卖方: 深圳沃优达科技有限公司 | We are Ideal Group, specialized in custom machining with more than 15 years experience, with 150+... | |

| 浅蓝色涤纶织带 | 卖方: 浙江天台艾德旺斯纺织有限公司 | 型号 WB-004 材质:涤纶 常规宽度:20mm、25mm、32mm、38mm、50mm、100mm 包装:100米/卷 颜色:可定制 涤纶织带用途广泛,其独特性能使其适用于各种用途。它由涤... | |

| Felt Logo Patch | 卖方: Nanjing Jiamei Garment Accessory Factory | This is a patch with wool felt or Velcro base, silicone or rubber logo embossed. It is widely use... | |

| Reflective Labels | 卖方: Nanjing Jiamei Garment Accessory Factory | always appear on safety uniforms but now it is fashion lucky devil by brands. It not only helps t... |