Insert Molding

Insert MoldingService

Insert molding is one category of custom injection moldingthat allows preformed parts or components, usually metal inserts, to be inserted into the plastic molded parts and to have a final product in one-step process. Insert moulding has characteristics as below:

A combination of two parts, preformed components (metal threaded inserts) and plastic molded parts (plastic resin);

One-step process is executed and avoids secondary assembly operations;

Insert the components into the parts to increase the functionality for the whole part.

As a professional china mold manufacturer, Keyplast insert molding factory, insert molding expert, insert moldingmanufacturer, insert molding supplieralso offer different varieties of injection mold toolings such as two shot molding, overmolding injection molding and materials used in injection moulding according to your different needs.

Insert Molding Process

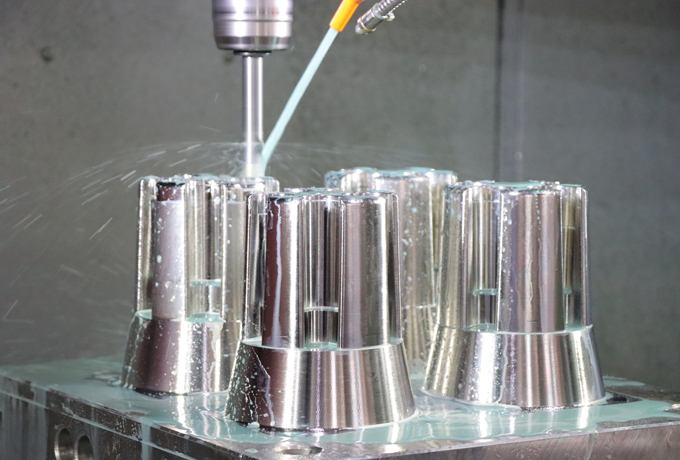

Firstly, prepare the finished molds well with preformed parts, like threaded inserts. Secondly, inject the melted plastic resins into the molds to create a whole part with threaded inserts. After sufficient cooling, the molded parts with threaded inserts will be ejected out. Insert molding process has key factors as below:

Insert Molding Process

What Is Insert Molding ?

What is insert moulding: Insert molding is a manufacturing process in which a preformed part (usually metal) is remolded using a heated thermoplastic resin to produce a single unit, called metal insert molding. Molded inserts can be simple objects, such as rods, threads, or blades, but they can also be complex.

There are many cases where this manufacturing method is needed to enhance the mechanical properties of plastic parts. The plastic molding process requires very high precision to ensure the correct molding of the final plastic part. Even the slightest deviation can completely destroy the results, so very strict quality control procedures are required. In fact, the insert molding process is closely related to the interface between the machine and the tool. Some high-precision machines can meet even the most demanding requirements of precision and reliability that only insert moulding can meet.

As one of insert molding suppliers, we will do our best to meet all the needs of customers.

There are many china injection molding companiesin China, but we are one of the best choices for you.

在线联系供应商

Other supplier products

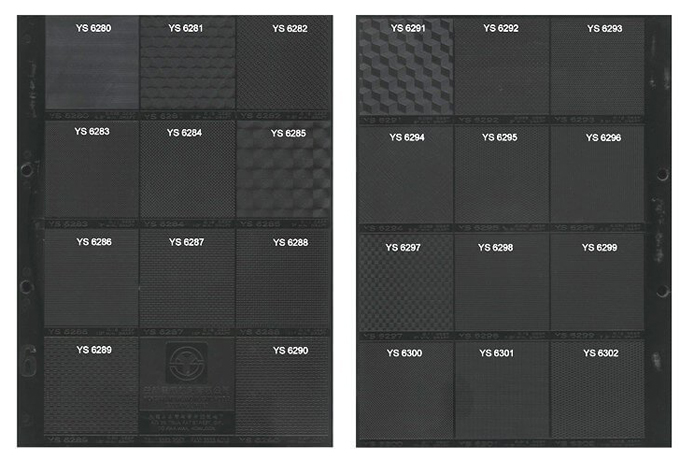

| Injection Molding Surface Finish | Injection Molding Surface Finish Do not use the finest whetstone, sandpaper, or abrasive polishing paste at the beginning of mold polishing, as yo... | |

| Over Molding | Over moldingof keyplast is a special plastic molding process. Overmolding custom injection moldingis similar to the two-color molding or two-shot m... | |

| What is the Difference Between Overmolding and Insert Molding? | What Is the Difference between Insert Molding and Overmolding Plastic injection molding is one of the most widely used processes for manufacturi... | |

| Plastic Injection Mould Tooling | Plastic molds are tools that are matched with plastic mold makingmachines in the plastic processing industry to give plastic products a complete co... | |

| Processing Performance and Conditions of ABS Injection Molding | Ⅰ. ABS Injection Molding Processing Performance (1) Because of the strong moisture absorption as well as high water content of ABS, the plastic pa... |

Same products

| Two-Shot Injection Molds | 卖方: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | 卖方: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | 卖方: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | 卖方: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | 卖方: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |