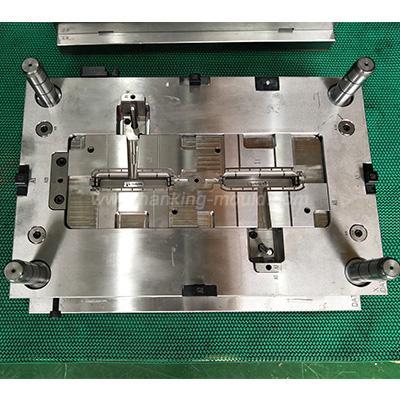

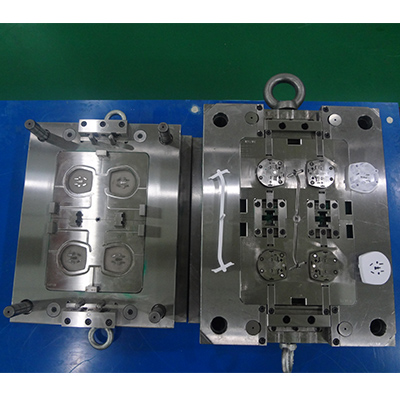

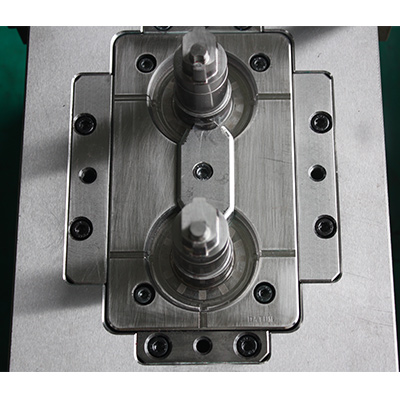

Prototype Mould

As a tool supplier whose goal is becoming an expert in the industry, Hanking Moldhas experience in handling many different types of mould, including but not limited to prototype molds.

Prototype mold Chinais a kind of test mould before mass production mould, customer makes test mould for design verification, product structure, part function analysis or produces small lot parts for other process verification. Prototype moulds are usually different from production moulds as they are not usually intended to be used for long periods of time.

Prototype molds are also called soft moulds or fast moulds, thus the cost of prototype molds are less than serious plastic moulds, when our designer is constructing a prototype mould, the first point he should learn is the purpose of customer to make this prototype mold.

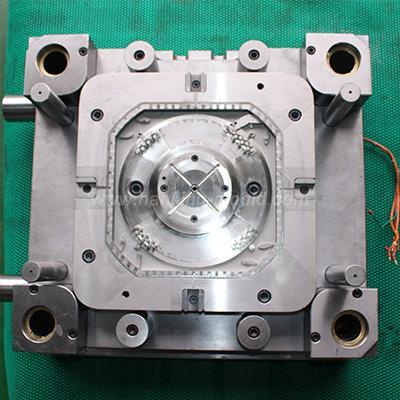

Some customers' goal is to manufacture low-cost pre-production molds that are tested and troubleshooting prior to final serious production to obtain more engineering data.

Some customers have reduced the overall product development cost of manufacturing low-cost prototype molds simply because of the low production of parts in demand.

Some clients are purposed to get fast samples or small batch quantities, for another process testing, such as electrical engineering testing, painting test, etc..

If you are not sure if the final parts are functional ok and how to build a production mould, we can make a prototype mold and we will give you professional suggestion that which prototype mold makingis high efficiency and low cost, and also HanKing provide very short lead time to save your time of product develop process.

在线联系供应商

Other supplier products

| Industrial Mould | Industrial mouldsis not a mold technology process, but a type of mold that is distinguished from the purpose of use. Generally speaking, products... | |

| Adapter Charger Housing Mold 496-1 | Mould Name: Adapter Charger Housing Mould Part Material: PC Product Size: 58.3*57.9*8.6mm Product Description: Adapter Charger Housing UK Mould Cav... | |

| Precision Mould | How to build a plastic precision mould? We have been manufacturing plastic precision moulds and componentsfor more than ten years. With our expe... | |

| Mold Trial | Plastic Mould Trialof Hankingtec In hanking mould’s trial shop, HanKing Mould Enginering Ltd.has7 injection molding machines with a clamping... | |

| Double Injection Mold Parts | Double Injection Mold Parts Part function: Plastic Lid for coffee machine Part Standard according to ISO 11496 Surface: SPI A-2 finish Flammabil... |

Same products

| ARM Cortex-A53 控制器支持 Linux Ubuntu,具有 4DI 到脉冲计数/数据控制,适用于智能工厂 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... | |

| ARM 2*Cortex-A53 电脑带2DI+2DO 支持Ubuntu储能 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... | |

| T507-H 处理器控制器 8GB eMMC 1GB DDR4 + 4RS485 支持 Linux 用于边缘计算 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... | |

| ARM 计算机 8GB eMMC 1GB DDR4+16GPIO 支持工业物联网的 Docker。 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... | |

| 1.4GHz 计算机配备 4*PGIO,支持 Ubuntu 用于储能 ARM 计算机。 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... |