PDC BIT

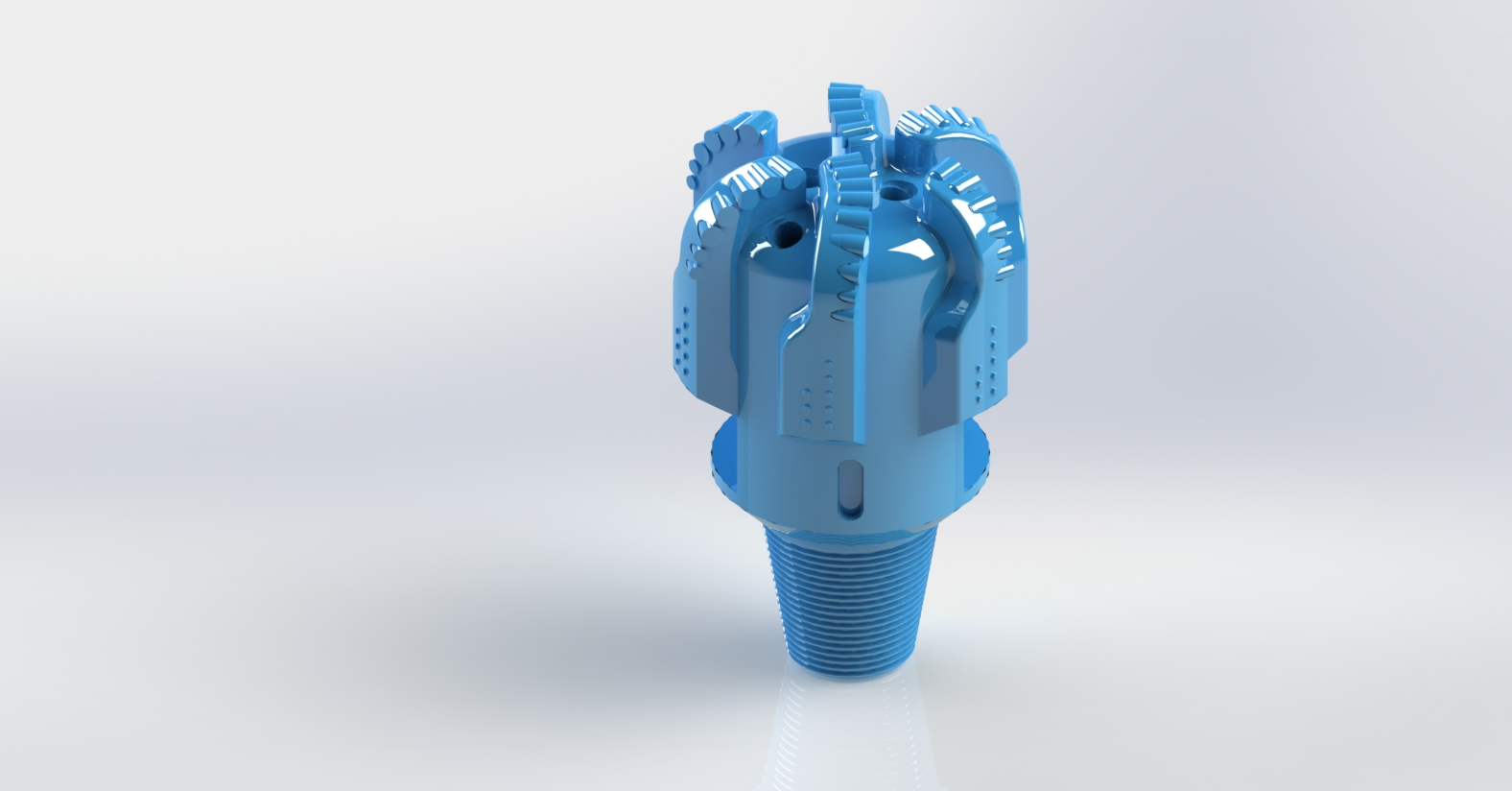

Big blade design: The blades of all PDC drilling series are raised and increased. Using oversized crumb running design can more effectively move drilling dicks, clean the drills, prevent drill bit mud bags, and increase mechanical drilling speed.

Anti -rotation design: The mechanical balance design is adopted, and the PDC drill bit design, orbital tooth design, and buffering block design are used to ensure the drill head anti -rotation performance.

Types Of PDC Bit

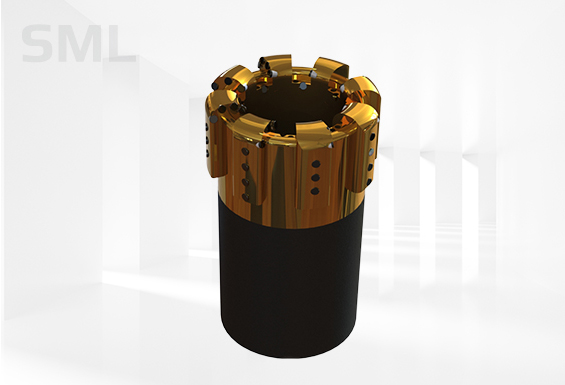

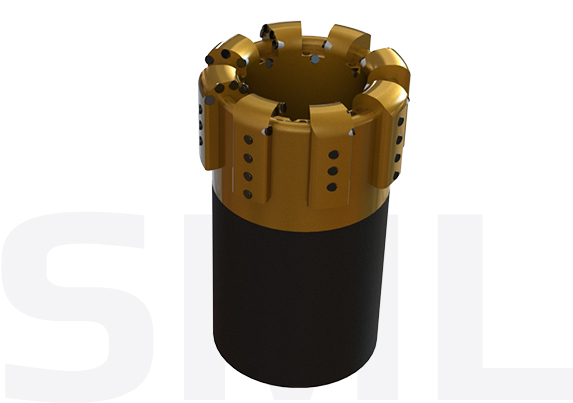

Matrix PDC Bit

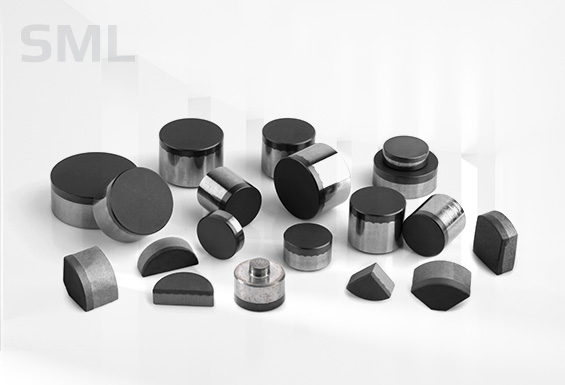

The diamond pdc bit is sintered with tungsten carbide powder, brazed on the tungsten carbide body with synthetic pdc cutter, and diameter retaining with artificial heat-stabilized polycrystalline diamond. The tungsten carbide body has high erosion resistance, wear resistance, high strength and good diameter retaining effect. The bit waterhole area can be designed according to the hydraulic parameters required by the drilling process, providing greater flexibility. The shape of the body can be designed according to the characteristics of the formation, and the change of the shape of the body is only required to change the mold without adding equipment.

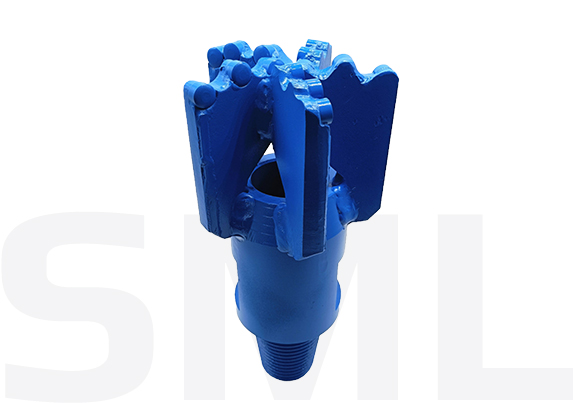

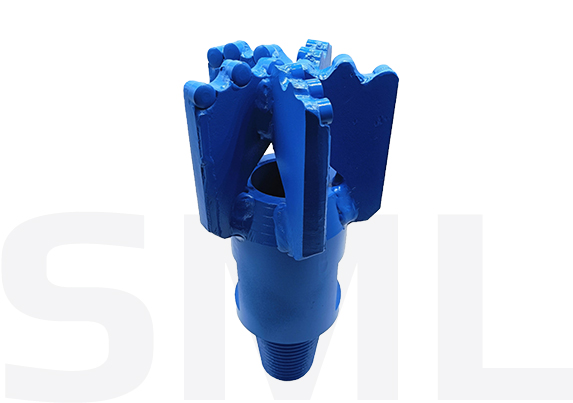

Steel PDC Bit

Steel pdc drill bits for sale is machined with chromium and molybdenum alloy steel. After the heat treatment, the drill body is drilled, and the synthetic PDC cutter is brazed into the tooth hole of the drill body. Tungsten carbide alloy or composite piece is used to maintain the diameter, and tungsten carbide wear resistant layer is welded to the blade to enhance the wear resistance and erosion resistance of the steel body bit. Steel body bits are less abrasive and more likely to wash away than tire bits, but steel body bits are cheaper and easier to repair.

PDC Drag Bit

PDC Drag bits work well for drilling in plastic and brittle formations like mudstone, muddy sandstone, shale, etc. as well as soft to moderately soft soils. SML's Drag bits are often created in specialized designs, frequently from customer drawings and size specifications.

PDC Core Bit

PDC core bits, also known as hollow bits, are a type of thin, multi-toothed tubular bit that contains embedded carbide chips.

Learn More

Matrix vs. Steel Body Bit

Steel-body

The upper part of the steel body is threaded to connect the drilling tool and the lower part is sintered to the body. The steel body is available in one piece or in two parts, i.e. the upper part is made of alloy steel with threads and the lower part is made of mild steel connected to the carcass. The upper and lower parts of the steel body are threaded together and then welded together.

Matrix-body

The carcass is inlaid with diamond particles of the matrix, is by a certain size of cemented carbide powder plus appropriate fusible metal for binder, pressed sintered surface and become. The shape of the carcass, i.e. the working profile, mainly refers to the geometry of the working surface and the size of the working area, which is designed according to the applicable different lithologies.

Different manufacturing methods:

The steel pdc rock bit is made of alloy steel to make the head of the multi-axis lathe to process the crown of the drill bit shaped and fitted, and then butt-welded to the joint.

The matrix body drill is made of various body powders and metal steel frames sintered in the mould at a temperature of 1000-15000 degrees and then butt welded to the joint.

Different strata:

Steel body bits are suitable for fast drilling in formations that are easy to drill without gravel and low compressive strength.

Matrix body bit is mainly used in difficult formations with high gravel and compressive strength. It is inherently stronger than the steel body bits.

What are PDC bits used for?

As pdc core drill bits have the characteristics of fast speed, more feed, long life, smooth working, less downhole accidents, low cost and wide range of application, they have been well received by the industry. Contact SML Tools, for the pdc drill bit price. Usually, there are three main uses of pdc bits: coalfield drilling and mining, geological exploration, and oil drilling.

Geological exploration. PDC Bits are suitable for soft to medium-hard rock formations and are widely used in geological exploration.

Coalfield drilling and mining. PDC Bits are mainly used for coal seam drilling and mining in coal mines. Generally speaking, the rock layer in the coalfield is relatively soft, and pdc bits are used in large quantities, such as PDC anchor bits and concave bits.

Petroleum exploration. PDC Bits are mainly used for drilling in oil and gas fields.

If you are looking for a reliable pdc bit company, don't hesitate to contact us!

There are many pdc bit manufacturers, but we are one of the best choices for you.

Other supplier products

|

|

5 Wings PDC Drag Bit |

Drag bits for water well drilling by using a polycrystalline diamond compact cutter, has high hardness and wear resistance, the drag bit blade betw... |

|

|

Steel PDC Drill Bit |

The entire bit body of the pcd drill bitis made of medium carbon steel and machined using a fabrication process. The bit crown is treated with a su... |

|

|

PDC DRAG BIT |

The PDC drilling drag bitis a composite of four main components: the bit body, the drag blade, the water diverter cap, and the nozzle. Forged from ... |

|

|

PDC BIT |

PDC bit Big blade design: The blades of all PDC drilling series are raised and increased. Using oversized crumb running design can more effectively... |

|

|

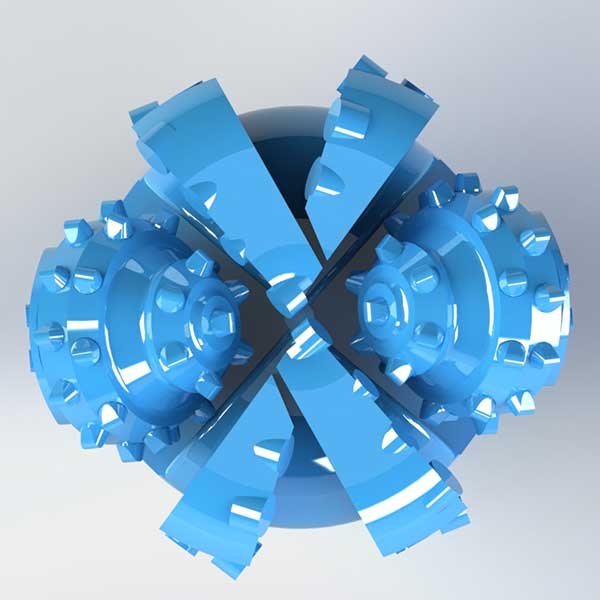

Hybrid Drill Bit |

The hybrid bituses a mixed cutting method. The tricone bit is to be broken by impact on the stratum, and then the PDC blade is cut to effectively p... |

供应产品

Same products