Shoe Sole Flexing Tester

Product Introduction:

The EN sole bending tester is used for 90 degree bending test of the sole of rubber, EVA and other zigzag shoes to detect its bending resistance and the ability to resist the growth of the incision, that is, the zigzag resistance.

Reference standard:

SATRA TM161. GB/T2099-2007. ENISO 20344-2011. EN ISO17707. ENISO-20344. DIN53543 and other standards.

Product Advantages:

Measures Key Durability Property: Directly evaluates the flex cracking and zigzag resistance of footwear soles, a vital indicator of product lifespan.

Standard Compliant: Designed to meet numerous relevant international and national standards for footwear sole flexing tests (EN ISO 17707. SATRA TM161. etc.).

Multiple Testing Stations: Available with options for testing multiple soles simultaneously (1 or 3 stations), increasing testing throughput.

Controllable Test Parameters: Allows for precise setting and control of the bending angle and flexing speed.

Automatic Functions: Includes features like one-key self-positioning for sample installation, simplifying operation and ensuring consistency.

Safety Features: Equipped with a protective cover, often with inductive safety interlocks, to ensure operator safety during testing.

Product Features:

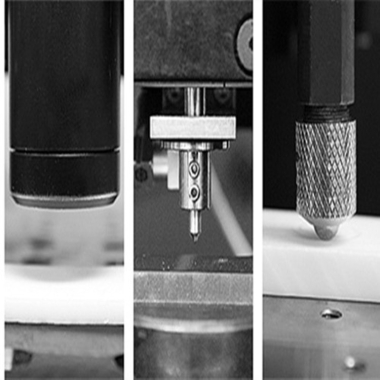

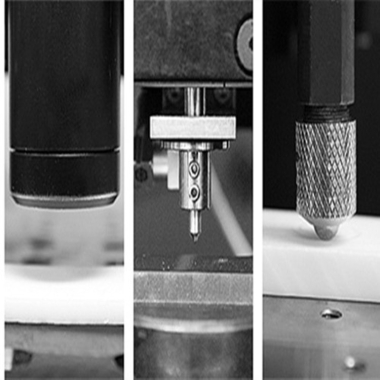

Flexing mechanism designed to bend the sole specimen through a 90-degree angle repeatedly.

Clamping system to securely hold the sole or sole component in place during the flexing action.

Multiple testing stations to test 1 or 3 soles simultaneously.

Adjustable speed control allowing the flexing rate to be set between 5 and 150 cycles per minute (cpm).

Point function: sample installation, one-key self-positioning function for automated or semi-automated sample setup.

Counter to record the total number of flexing cycles performed during the test.

Zigzag shaft with a specific diameter (30mm), likely a key component of the bending mechanism.

Protective cover, often inductive, to shield the operator from moving parts during the test.

Robust construction to withstand continuous operation.

Technical parameters:

1. the number of stations: 1. 3 stations (at the same time can measure 1. 3 outsole)

2. bending Angle: (90±2)º

3. speed: 5——150cpm adjustable

4. point function: sample installation, one-key self-positioning function

5. volume: 86*46*80cm

6. zigzag shaft diameter: 30mm

7. Protective cover: inductive safety cover

8. Power supply: AC220V, 10A

在线联系供应商

Other supplier products

| Electrolyte wettability test system | Standard ASTM D724-98: Standard Test Method for Surface Wettability of Paper (Angle-of-Repose Method Adapted) ISO 8296: Plastics – Determin... | |

| Thermal Cold Cycle Testing Machine | Standard BS 7291: Compliant for thermal cycling tests on thermoplastic pipe systems (1769 Series with pressure chamber). Adaptive Certification: ... | |

| Sock wear tester | Product Information: Socks wear tester is a special equipment, mainly used to test the wear resistance of socks material. It evaluates the comfort... | |

| Pilling assessment viewer | Universal pilling pilling viewer/Pilling Pilling Rating tester By comparing the sample to the standard card under the specified light source to obt... | |

| Button Sewing Machine | Applications: Be applicable to Button-attaching for ordinary button with two or four holes. Shanked button and others are also can be sewed with... |

Same products

| Scott Flex Tester | 卖方: 标准集团 | Product Introduction: Scott kneading tester is suitable for back and forth kneading resistance o... | |

| NEU nanofiber electrospinning device | 卖方: 标准集团 | Content The Nanofiber Electrospinning Unit uses electrospinning techniques to safely and easil... | |

| KK03 Scratch tester | 卖方: 标准集团 | Product Introduction: With the continuous expansion of the use of plastic molding products, from... | |

| KK02 Scratch tester | 卖方: 标准集团 | Product Introduction: With the continuous expansion of the use of plastic molding products, from... | |

| KK01 Scratch tester | 卖方: 标准集团 | Product Introduction: With the continuous expansion of the use of plastic molding products, from... |