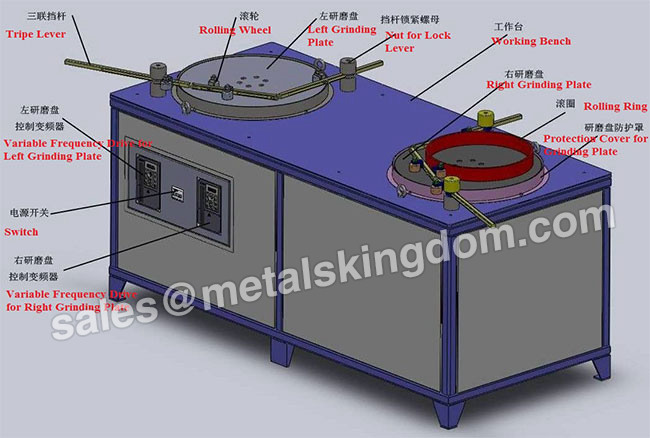

MT-500X Valve Core Grinding Bench

MT-500X Valve Core Grinding Bench

Stationary valve grinding machine is suitable for the valve disks of gate valves and globe valves,it is widely applied in coal-fired power petrochemical steel metallurgical paper and other industriesvalve grinded machineFeature:1、Stationary, more stable and durable2、double station design,Easy to operate, higher efficiency

1)diameter of Grinding disc: Dia500mm

2)Scope of Grinding:Dia25-Dia300mm

3)Quantity of grinding disc:2 pcs

4)Application : valve core of plane globe valve, gate valve .

5) Motor Power:1100W,Double motor.

6)Speed regulation mode:Variable frequency stepless speed regulation

7)Power supply: 220 V/50Hz

8) motor power: 1100W x2=2.2kw double motor

Stationaryvalve grinding machineis suitable for the valve disks of gate valves and globe valves,it is widely applied in coal-fired power petrochemical steel metallurgical paper and other industries

1.Connect the 380V power supply and turn on the total power supply.

2.Before starting the equipment, check whether there is any foreign body around the grinding disc and deal with it.

- safety valve grinder machineOperation instructions:

(1) Device startup key: RUN Device stop key: STOP Forward and Reverse conversion key: JOG

(Note: when the forward and reverse conversion is done, the position of the triple lever should be adjusted accordingly).

Speed adjustment: knob on the panel rotation adjustment or up and down key adjustment.

(2) Other key suggestions should not be adjusted so as to avoid confusion.

(1) Before grinding the spool, adjust and fix the triple lever according to the size of the spool, and install the roller assembly on the triple lever, adjust the position and press firmly. Apply the corresponding abrasive grout on the grinding plate. (see grinding process)

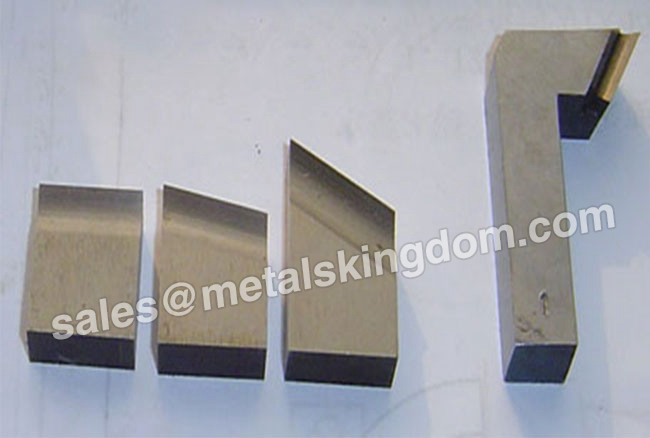

(2) Grinding and repair of round spool.

The spool is placed in the middle of the angle between the three retaining bars and contacts with the roller to start the equipment for grinding. Or put the spool roller between the angle of the triple bar and contact with the roller, put one or more spools into the roller, start the equipment for grinding.

(3) Grinding of Gate valve spool:

Place the spool roller between the angle of the triple lever and contact the roller. Place one or more spools in the roller and start grinding.

(4) Hand held grinding:

The small spool with less damage will put the spool on the grinding disc, and start the equipment to carry out grinding by hand.

(5) the left and right two lapping plates are controlled by two transducers on the left side and the right side respectively, and the operation mode is the same.

- safety valve testing machineGrinding process:

The abrasive paste with different sizes should be replaced according to different grinding needs. The abrasive paste is stirred and coated on the abrasive plate with machine oil. Before grinding, the high point burr on the spool should be removed before grinding.

1)Rough grinding:

Choose 60 -120# abrasive paste to remove defects such as groove marks, pits, scratches, etc.

2).Fine grinding:

Grinding around 240# or so is used to remove minor scratches.

3). Finish grinding:

More than 400 #grinding paste is used to finish the polishing.

Looking for Valve Grinding Machine, Valve Pressure Testing Table, Pipe Cutting Machine? Metals Kingdom waiting to create business relationship with you. With 24 years’ export experiences, our Valve Grinding Equipment, Valve Test Table, Valve Pressure Benchhave been welcomed in international markets. As fames China pipe beveling and cutting machine, High quality and factory price will give you.

If you are interested in our valve grinders, you can click hereto visit our website.

在线联系供应商

Other supplier products

| MZ-600 Portable Gate Valve Grinding Machine , Portable Valve Grinding and Lapping Machine For Gate Valves ,Portable Valve Grinding and Lapping Machine | MZ-600 Portable Valve Grinding and Lapping Machine For Gate Valves Technical indicators Applicstion:Gate Valve Seat,Gate Valve Core. a) grinding... | |

| Portable Gate Valve Grinder for Dn200-600mm. | Manufacturer of Valve grinder from China ,Metals Kingdom Industry LimtedM-600 Portable Valve Grinding Machine1.Characrer:M-600 portable valve grind... | |

| M-300 Portable Gate Valve Grinding Machine | M-300 Portable Gate Valve Grinding Machine Portable Valve Grinding and Lapping Machine For Gate Valves Technical Parameter 1)Applicstion:Gate Val... | |

| PKN-150 Portable Inner Expand Type Pipe Beveling Machine | PKN Inner Clamped Pipe Beveling Machine PKN series pipe beveling machineis an inner up mounted card type pipe beveling machine, using single p... | |

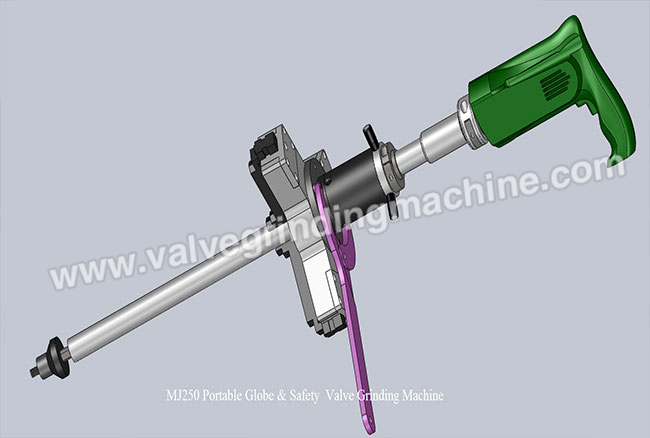

| DN80-250mm 3"-10" MJ250 Portable Relief Valve Grinding Machine Portable Valve Grinding and Lapping Machine For Safety Valves Portable Valve Grinding and Lapping Machine | Portable Valve Grinding and Lapping Machine For Safety Valves Portable Globe Valve Grinding MachineSummarization MJ-250 Portable Valve Grinding M... |

Same products

| HM Pumex Grinding Machine | 卖方: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| XZZ Z1 Pro 电动研磨笔 IC 抛光工具 | 卖方: 深圳维客修科技有限公司 | XZZ Z1 Pro 电动抛光笔,配备多种磨头,满足不同类型的手机主板 CPU IC 研磨和维修需求。2025 XINZHIZAO XZZ USB 充电式抛光研磨笔,适用于手机维修。 XZZ ... | |

| Scraper Grinding Machine | 卖方: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| IC抛光用小型电动研磨笔 | 卖方: PHONEFIX technology Co.,Ltd | 描述E288-02小型手持研磨机迷你主板CPU IC抛光笔雕刻工具。电动研磨笔适用于手机维修,IC CPU抛光,玉石玛瑙,核雕,木雕,研磨铝板,印刷电路板和环氧板以及手机液晶屏残留OCA胶去除。... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | 卖方: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |