Busbar Insulation Coating

The busbar insulation paintis made from special silicone rubber, high-performance busbar insulation material and other polymers by polymer blending technology. Its basic structural unit is silicon - oxygen chain while its side chain is connected by silicone with another organic radical group. Therefore, this structure makes the coating well combine the properties of both organic and inorganic compound. This product can used for the equipment and components which need protection of insulation, thermos conduction, fire retardant, dampness-proof, etc., such as bare wire, busbar, cable, high-power generator, dry-type reactor, dry-type transformer, switch cabinet and so on, it's quite suitable for the electrical equipment which operated in contaminated and humid environments.

Product Standard of Busbar InsulationCoating:

DL/T 627-2012 Room Temperature Vulcanized Silicone Rubber Anti-Pollution Coating for Insulators

IEEE 1523 IEEE Guide for Application, Maintenance, and Evaluation of Room Temperature Vulcanized (RTV) Silicone Rubber Coatings for Outdoor Ceramic Insulators

Contact us get more details about RTV-II Silicone Rubber Coating, such as TDS, Application Method, OEM etc.

Product Features of Busbar Insulation Coating:

Product Standard of Busbar Insulation Coating:

DL/T 627-2012 Room Temperature Vulcanized Silicone Rubber Anti-Pollution Coating for Insulators

IEEE 1523 IEEE Guide for Application, Maintenance, and Evaluation of Room Temperature Vulcanized (RTV) Silicone Rubber Coatings for Outdoor Ceramic Insulators

There is epoxy powder coated busbar insulationand other busbar insulator types, if you want know more,please contact us.

Contact us get more details about RTV-II Silicone Rubber Coating, such as Busbar Insulation Material,TDS, Application Method, OEM etc.

|

Item |

Silicone Rubber Insulation Coating |

Heat Shrink Tube |

|

Electrical Insulation |

Excellent electrical insulation. Breakdown Voltage is more than 25 kV/mm. |

Common performance. |

|

Cover Effect |

Excellent adhesion.The coating layer is intense, it could strongly stick to the equipment surface and could well resist to the corrosion caused by acid, alkali, salt and air. |

Common cover effect especially in the connection part. |

|

Thermal Conductivity |

The coating has closely attached to the conductor and has good thermal conductivity could better release the heat of equipment. Its thermal conductivity is 0.2W/ (m. k), which is ten times then air. |

Relatively poor due to there is air gap between the tube and equipment. |

|

Flame Retardant |

Hard to burn and has good fire retarding ability up to FV-0 Class. |

Easy to deform, crack and broke. |

|

Application |

Favorable hardness makes its construction time is short. (less than one working day)It can well fit and protect the surface of special shaped equipment or components and special connection position so that to make the conductors as one. |

Long construction time and need to disassemble the equipment.It’s easy to crack and broken for the coating on the special shaped equipment or components and the connection or twist place. |

|

Maintenance |

Easy to maintain and repair. The coating will not affect the dismounting of screw or bolt. Moreover, if recoating, the new coating can have integrated fuse with the old coating tightly. |

Although it’s also convenient to maintain and repair, but the connection place is easy to peel and broke. |

|

Ageing Resistance |

Good hydrophobicity and resistance to ageing, dampness, ozone, radiation, UV, etc. make it free of maintenance and can serve for a long time. Its service life could be more than 20 years. |

Poor ageing resistance, its service time is about 5 years or even less especially in some bad environment the cracking and break phenomenon will happen. |

|

Economic |

Excellent performance at reasonable cost. |

Lower cost. |

AllRuisensilicone rubber coatingproducts will be 100% QC before shipping to ensure good quality of each piece.

在线联系供应商

Other supplier products

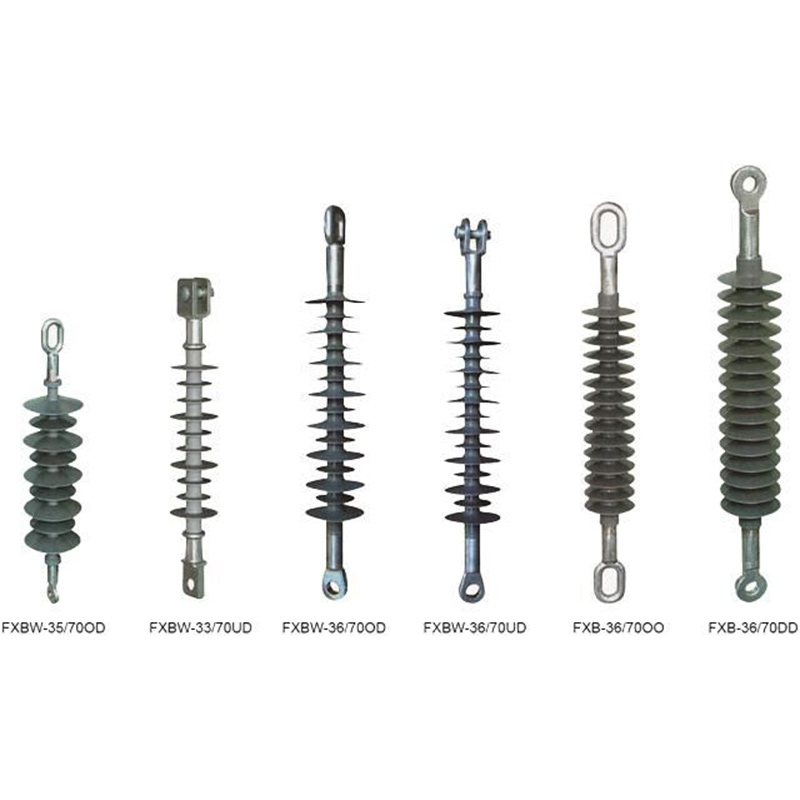

| Composite Insulator | We offer different kinds of composite type insulatorfor substation. Contact us get more details about composite insulator, such as TDS, Application... | |

| High Voltage Insulator Coating Series | High Voltage Insulator Coating(HVIC) is used on excessive voltage insulators to forestall flashover and arcing, particular in severely contaminated... | |

| Anti-Algae & Anti-Fouling Coating | Leveraging upon our experience, we have become a prominent Anti-Algae & Anti-Fouling Coatings (RTV-ZB) Manufacturer, Exporter and Supplier in C... | |

| Hollow & Bushing Insulator | We offer different kinds of Hollow & Bushing Insulator for Substation, such as Circuit Breaker (CB), GIS, Post Insulator, Disconnector, Potenti... | |

| Construction Waterproof Coating | K11 General Type Waterproof Coating In recent years, with the improvement of people's living standard, the living conditions of the requirements i... |

Same products

| Epoxy/Polyester Powder Coatings | 卖方: Standard International Group (HK) Limited | Feature: -Good bond ability and mechanical performance -Smooth and glossy -Certified chemical ... | |

| Polyester Clear Powder Coatings | 卖方: Standard International Group (HK) Limited | This series of product are made of polyester resin (as hardener) and highly transparentmaterials.... | |

| Acrylic Clear Powder Coatings | 卖方: Standard International Group (HK) Limited | Feature: -Excellent exterior exposure durability -Excellent durable high gloss -Excellent clar... | |

| Polyurethane Powder Coatings | 卖方: Standard International Group (HK) Limited | Feature: -Excellent exterior exposure durability -Good flowing -Excellent chemical resistance ... | |

| MDF Powder Coating | 卖方: Standard International Group (HK) Limited | Feature: -Environmental friendly -No solvents and volatile organic compounds involved which are... |