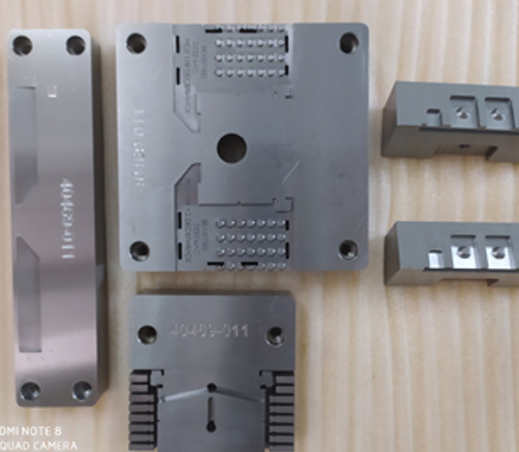

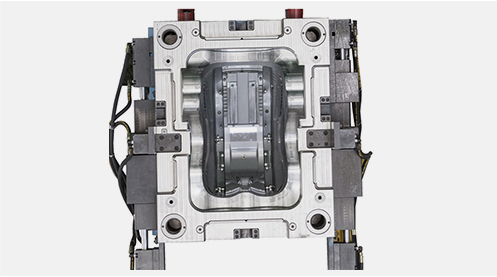

Electronics Product Part

Electronics Product Part

With the fast growth in the electronic industry, the demand for injection molding electronicsis much higher. The injection molding electronics can be intricate or simple.

Intricate injection molding electronics can be economical because they combine many parts into one piece which saves the cost of different types of separate pieces. As a professional plastic injection moulding productsmanufacturer, GM-TECH provides injection molding electronics such as mobile s, computers, and sophisticated connectors.

Features of injection molding electronics parts

Be able to use a different plastic simultaneously

As an electronics plastic manufacturer, we can utilize different types of plastic at the same time by using injection molding electronics. This can be achieved with the help of co-injection molding.

Lower the manufacturing cost

Plastic injection molding is an intelligent process with some automatic machines which reduce manufacturingplastic mold cost.

Form the finished appearance

Custom plastic injection moldingelectronics make sure the parts produced are near to the finished produces. Thus, it hardly takes any time to arrange the rest of the work.

The Specification of injection molding electronics Product Part

|

Part material |

PA66 + 30gf |

|

Cavity |

1 |

|

Mould steel |

|

|

Mould steel |

|

|

Mould life |

100W |

|

Mould standard |

HASCO |

|

Mould structure |

3 sliders |

|

Exporting country |

Germany |

|

Leadtime |

5 weeks |

|

Mould quality customer satisfaction |

96% |

|

FAI pass rate |

99% |

|

Project cooperation service customer satisfaction |

98% |

How do Injection Molding Electronics Parts Work?

The series of events that occur during the injection molding electronics molding process is called the injection molding cycle. When the mold is closed, the polymer of plastic molded products is injected into the mold cavity. Once the cavity is filled, the pressure is maintained to compensate for the shrinkage of the plastic injection molded part material. In the next step, the screw rotates to give the screw before the next lens. This allows the screw to retract when preparing for the next stitch. Once the part is sufficiently cooled, the mold opens and the injection molding electronics are ejected.

If you want to know more applications of mold tech china, please visit our website.

在线联系供应商

Other supplier products

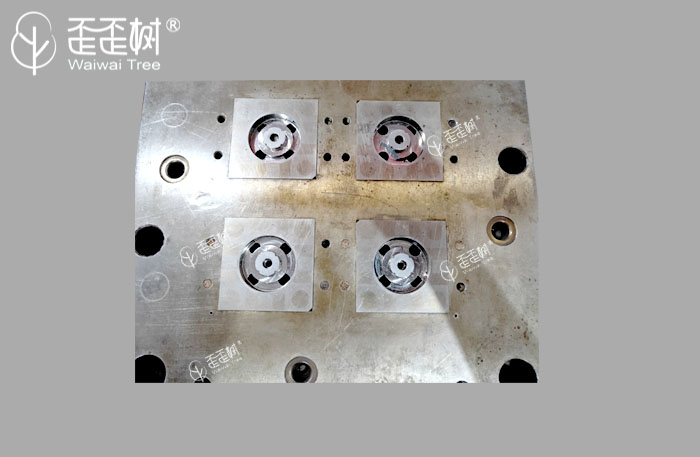

| Mould Component | Mould Componentare also a part of the mould.GM-TECH not only produces precision moulds but also provides customers with high-precision, low-cost mo... | |

| Injection Moulding Products | GM-TECH has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. We are also experienced in th... | |

| Injection Moulding Products | GM-TECH, injection moulding manufacturers,has been manufacturing tools for injection molding of plastics for various industries for more than 10 ye... | |

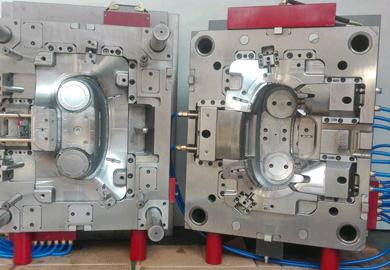

| Home Appliance Mould | Household appliances mouldcombines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, h... | |

| Electronics Product Mould | Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics ... |

Same products

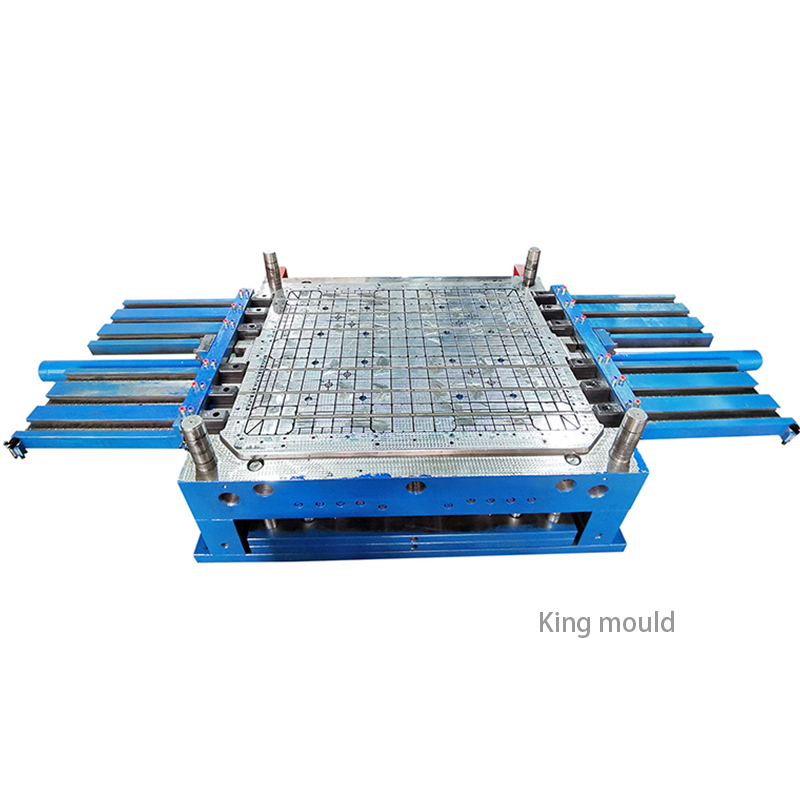

| Plastic Injection Lightweight Pallet Mould | 卖方: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | 卖方: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | 卖方: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | 卖方: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | 卖方: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |