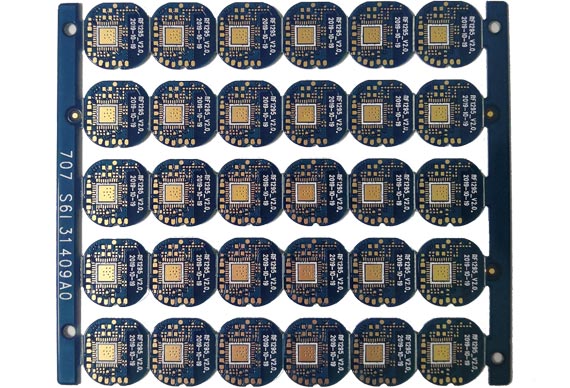

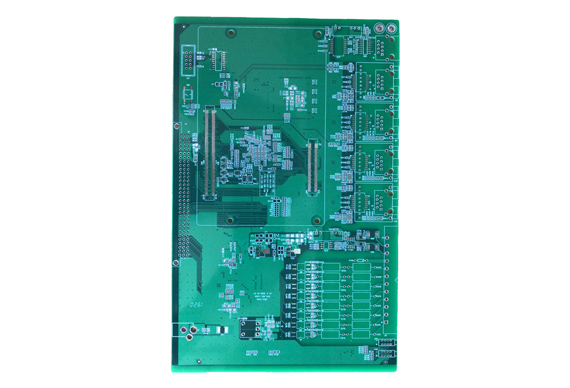

PLATED THROUGH HOLE PCB / PTH PCB

PCB Via Hole/ PTH PCB

There are three common types of drilled holes in the printed circuit board:pcb via plating, blind via hole, and buried via hole. Therefore, PCBs are classified according to drilling methods and can be divided into plated through-hole PCB, blind via hole PCB, and Buried via hole PCB.

PTH is the most common drilling method, and it is common in various types of PCBs. SPEEDAPCB has been focusing on the production of various PTH (plated through hole PCB-PTH PCB), buried via hole PCB and blind via hole PCB.

HAVE A QUESTION OR REQUEST?

Click below, we’ll be happy to assist.

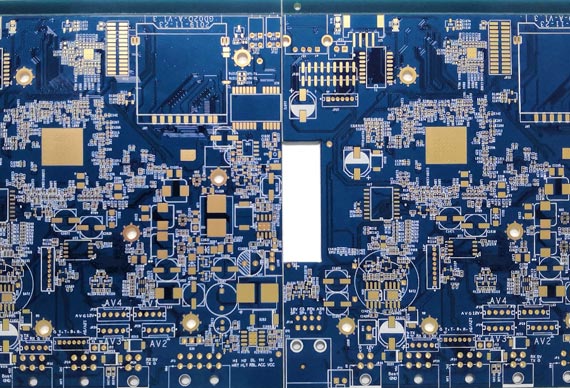

Drilling Method of Plated Through Hole PCB

Plated Through Hole, the copper foil lines between conductive patterns in different layers of the circuit board are connected or connected with this type of hole, but the copper legs of the component lead or other reinforced materials cannot be inserted. The PCB is formed by the accumulation of many copper foil layers. The copper foil layers cannot communicate with each other because each layer of copper foil is covered with an insulating layer, so they need to rely on via for signal connection.

The through hole of the circuit board must pass through the plug hole to meet the customer's needs. In changing the traditional aluminum sheet plugging process, the solder mask and plug hole on the circuit board surface are completed with a white net to make its production more stable and the quality more reliable , More perfect to use. The vias help the circuits to be connected to each other. With the rapid development of the electronics industry, higher requirements are also placed on the PCB manufacturing process and surface mount technology. The plugging process for vias came into being, and at the same time, it must meet the following requirements:

Through-hole boards are common in all fields and are one of the most common PCBs.

Generally, the mobile board or PDA board has a board that uses a combination of blind and buried holes. The buried hole can reduce the probability of signal interference, maintain the continuity of the transmission line's characteristic impedance, and save routing space. Circuit board design. This type of board requires high technical content and accurate accuracy, so relatively speaking, the requirements for factory equipment are much higher than ordinary multilayer boards, and the cost of such circuit boards will be much higher than ordinary Shelf should be high.

Parameters of Plated Through Hole PCB

|

Items |

||

|

Max board size |

580X700mm |

|

|

Boar Material |

FR-4,Aluminum, High Tg FR4,CEM3,etc. |

|

|

Min trace width/ space (inner layer) |

4mil/4mil(0.1mm/0.1mm) |

|

|

Min PAD (inner layer) |

5 mil(0.13mm) |

|

|

Min thickness(inner layer) |

4 mil(0.1mm) |

|

|

Inner copper thickness |

||

|

Outer copper thickness |

||

|

Finished board thickness |

||

|

±0.10 mm |

±0.10 mm |

|

|

Board thickness tolerance control |

±10% |

±10% |

|

±10% |

±10% |

|

|

Inner layer treatment |

brown oxidation |

|

|

Layer count Capability |

1-30 LAYER |

|

|

alignment between ML |

±2mil |

|

|

Drill hole diameter |

||

|

Aspect ratio of plated hole |

10:01 |

|

|

Hole precision |

±2 mil(±0.05mm) |

|

|

tolerance for Slot |

±3 mil(±0.75mm) |

|

|

Hole diameter tolerance(PTH) |

±3 mil(±0.075mm) |

|

|

Hole diameter tolerance(NPTH) |

±1mil(±0.025mm) |

|

|

Max Aspect Ratio for PTH |

8:01 |

|

|

Hole wall copper thickness |

15-50um |

|

|

Alignment of outer layers |

4mil/4mil |

|

|

Min trace width/space for outer layer |

4mil/4mil |

|

|

Tolerance of Etching |

+/-10% |

|

|

Thickness of solder mask |

on trace |

|

|

Thickness of solder mask |

at trace corner |

≥0.2mil(5um) |

|

Hardness of solder mask |

On base material |

≤+1.2mil |

|

6H |

Finished thickness |

|

|

Alignment of solder mask film |

±2mil(+/-50um) |

|

|

Min width of solder mask bridge |

4mil(100um) |

|

|

Max hole with solder plug |

||

|

Surface treatment |

HAL (Lead or Lead free), immersion Gold, Immersion Nickel, Electric Gold finger, plated Gold, OSP, Immersion Silver.carbon oil,etc. |

|

|

Max Nickel thickness for Gold finger |

280u"(7um) |

|

|

Max gold thickness for Gold finger |

30u"(0.75um) |

|

|

Nickel thickness in Immersion Gold |

120u"/240u"(3um/6um) |

|

|

Gold thickness in Immersion Gold |

2u"/6u"(0.05um/0.15um) |

|

|

Impedance control and its tolerance |

50±10%,75±10%,100±10% 110±10% |

|

|

Trace Anti-stripped strength |

≥61B/in(≥107g/mm) |

|

|

bow and twist |

||

SPEEDA Technology is an electronic technology company formed by a team with an average of 10+ years of electronic industry experience. As one of the best pcb manufacturers in china, the company is mainly engaged in the design, R&D (research and development), manufacturing, and sales of various printed circuit boards. We provide pth board,pcb board with holesand etc for sale.Our products are widely used in communication equipment, computer and network equipment, consumer electronics, automotive electronics, industrial control, new energy, rail transit, and other industries. We provide customers with a "one-stop" service, that is, an integrated service system consisting of printed circuit board design optimization, small-batch sample production, batch production, and after-sale services. Adhere to quality first, service first, to improve customer satisfaction as the goal continuously.

SPEEDA, Your Best Business Partner.

在线联系供应商

Other supplier products

| MORE PRINTED CIRCUIT LAYERS BOARD——MULTILAYER PCB | A multilayer printed circuit boardhas more layers than a double-sided printed circuit board. It has many circuit layers between the top and bottom ... | |

| LEAD FREE HASL PCB / IMMERSION TIN PCB | Lead-free HASL is to coat a layer of tin-lead alloy on the copper surface to prevent the oxidation of the copper surface and provide a good welding... | |

| Medical PCB Manufacturer & Assembly | Electronics makes a significant contribution to the health-the nursing industry, as a diagnostic, monitoring, and treatment device. As the developm... | |

| SPEEDA PCB BOARD PRODUCT | PCB is the printed circuit board, which is one of the important parts of the electronics industry. Almost every kind of electronic equipment, from ... | |

| IMMERSION SILVER PCB - PRINTED CIRCUIT BOARD | The immersion silver process of immersion silver pcbmanufacturing is between OSP and immersion nickel / gold, and the process is relatively simple ... |

Same products

| Header Card | 卖方: Dongguan Xiaolong Packaging Industry Co.,LTD | Our new range of custom header cards and bagsis a high-quality printing paper that is excellent f... | |

| Grey Cardboard | 卖方: Dongguan Xiaolong Packaging Industry Co.,LTD | Grey cardboardis double grey industrial cardboard, which is produced from a kind of recycled wast... | |

| Green Colored Paper Wholesale | 卖方: Dongguan Xiaolong Packaging Industry Co.,LTD | Colour paper greenis perfect for kids who love to draw and do crafts. Its smooth and clean surfac... | |

| Gift Paper Boxes | 卖方: Dongguan Xiaolong Packaging Industry Co.,LTD | Gift-giving has been a tradition for centuries, and the perfect gift box of paper, it can make th... | |

| Food Packaging Box | 卖方: Dongguan Xiaolong Packaging Industry Co.,LTD | Food Packaging Box from Xiaolong is the perfect solution for anyone looking to transport food ite... |