Working Principle of the Saw Dust Pellet Machine

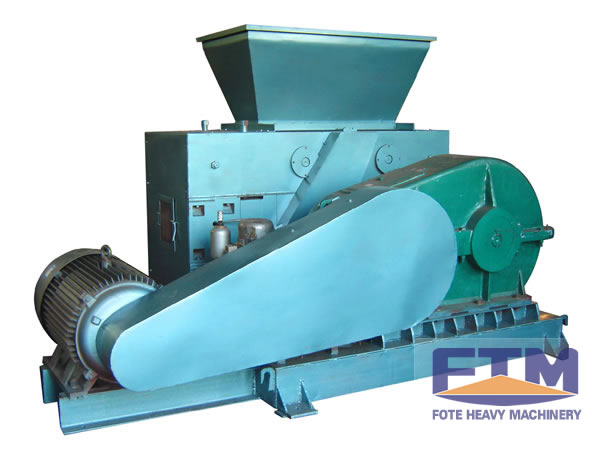

Researches on the working principle of sawdust pellet mill are of key importance for the performance improvement. The following content will analyze the working principle of saw dust pellet machine from the points of working efficiency, service life and energy conservation. Sawdust pellet mill is made of parts like pellet maker, conditioner, feeder, regulating mechanism and lubricating system. saw dust pellet machine After being fed by the feeder and modulated by the conditioner, raw materials are delivered into the pellet maker. Through the mutual movement of press roller and ring die, raw materials are extruded out from the die holes and cut by the blades into pellets with desirable size. Driven by the main motor, ring die revolves at a certain speed. Through the guiding mechanism, raw materials are delivered into the distance between press roller and ring die. On account of the friction force between ring die and raw materials, press roller and raw materials, press rollers can rotate. Along with the rotation of ring die and press roller, raw materials are extruded into the holes of ring die. If extrusion force is larger than the friction force of die holes on raw materials, raw materials will be extruded out through the die holes. Under the work of blades, finished products can be in the form of pellets with desirable size. On the way to develop the saw dust pellet machine, Fote stays awake before the temptations and interests, never does the impractical propaganda and treats every thing with the practical attitude. Enjoy the discounts on website! Fote Heavy Machinery: Fote Official Email:

Other supplier products

|

|

How Does VSI Sand Maker Work? |

VSI crusher, also named as VSI sand maker, is a kind of typical machine for making the sand aggregates. Since the crushing ratio of VSI crusher is ... |

|

|

Points Related With the Work of Straw Pellet Mill |

Different from the traditional way to make pellets, straw pellet mill is regarded as the most ideal way to make pellets. Raw materials, being deliv... |

|

|

Factors for Molding Rate of Coal Briquette Plant |

With wide application ranges, the coal briquette machine can be used to suppress materials like coal powder, iron powder, coking coal, aluminite po... |

|

|

Drying Stages of Fote Sludge Drying Machine |

According to the changes of drying speed in rotary drum of sludge drying machine, drying process is classified into three stages, respectively name... |

|

|

Wonderful Features of Liquid Fuel for Slurry Dryer |

As we all know, for fuels used to heating the coal slime dryer, most of them are in liquid. Then, for liquid fuels, they are generally the heavy oi... |

供应产品

Same products