SMT ASSEMBLY

SMT refers to surface mount technology, which is the most popular technology and production process applied in the circuit board assembly line. In the pick and place system, it is the circuit assembly technology that mounts no-lead or short-lead surface assembly components on the surface of a printed circuit board or other substrates, then solders and assembles them by reflow soldering or IP soldering. The advantages of SMT chip mounter: high assembly density, the small size of electronic products, lightweight, high reliability, strong vibration resistance, easy to realize automation, help customers improve production efficiency, reduce costs by 30%-50% by saving materials, energy equipment, manpower, time, etc.

TronStol is a professional SMT machine manufacturer that supplies you with matured PCB/SMD/smt production equipment, contact us to get more information!

SMT ASSEMBLY EQUIPMENT MANUFACTURER

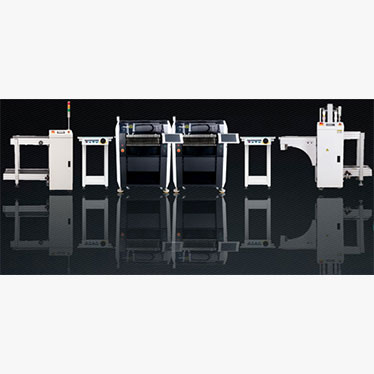

SMT Assembly Line

TronStol, one ofcompetitive smt equipment suppliers, provides customers professional SMT production line services and other services with different requirements.

Other SMT Line Machines

Reflow Oven; Stencil Printer; Conveyor; Loader and Unloader; Solder Paste Mixer; Accessories.

THE ADVANTAGES OF SMT ASSEMBLY

SMDassembly devicemakes the creation and production of electronic circuits easier. Surface mount technology machines are especially important in complex circuits. Higher levels of automation have saved our entire industry time and money. Smaller size and reduced weight are the two main advantages of SMT. Components can be more closely aligned, and the final product will be more compact and lighter.

The main advantages of SMT Assembly:

- electronics assembly line machines(surface mount assembly equipment) requires fewer circuit boards. Welding can be customized. The components are connected with solder, which is also glue. Better performance can be achieved under shock or vibration mechanical conditions. SMT connection is more reliable.

SMT ASSEMBLY PROCESS

The assembly process of SMT and its process flow mainly depend on the type of surface mount component (SMA), the types of components used, and the conditions of assembly equipment. In general, SMA can be divided into three types of single-sided mixed assembly, double-sided mixed assembly and full-surface assembly, a total of six assembly processes. Different types of SMA have different SMT assembly process, and the same type of SMA can also have different SMT assembly process.

Choosing an appropriate assembly method according to the specific requirements of the patch processing and assembly products and the conditions of the surface mount machines are the basis for efficient and low-cost assembly and production. It is also the main content of the SMT process design.

The first type is single-sided hybrid assembly that is SMC/SMD and through-hole plug-in components (17HC) are distributed on different sides of the PCB, but the welding surface is only one-sided. This type of assembly process all use single-sided PCB and wave soldering (currently double-wave soldering is generally used).

The second type is double-sided hybrid assembly. SMC/SMD and THC can be mixed and distributed on the same side of the PCB. At the same time, SMC/SMD can also be distributed on both sides of the PCB. Double-sided hybrid assembly adopts double-sided PCB, double wave soldering or reflow soldering. In this type of assembly method, there is also a difference between the first-sticking process and the after-sticking SMC/SMD. Generally, it is reasonable to choose according to the type of SMC/SMD and the size of the PCB. Usually, the first-sticking process is more adopted.

The third type is full-surface assembly, with only SMC/SMD on the PCB and no THC. As the current components have not yet fully realized SMT, there are not many such assembly forms in practical applications. This type of assembly method is generally assembled on a PCB or ceramic substrate with fine-line patterns, using fine-pitch devices and reflow soldering processes.

DIFFERENCE BETWEEN SMT AND SMD ASSEMBLY

SMD is the abbreviation of Surface Mounted Devices which is one of SMT (Surface Mount Technology) components, including CHIP, SOP, SOJ, PLCC, LCCC, QFP, BGA, CSP, FC, MCM etc.

Surface mount components were introduced about twenty years ago, and this opened a new era. From passive components to active components and integrated circuits, they eventually become surface mount devices (SMD) and can be assembled by pick and place equipment. For a long time, people believed that all pin components could eventually be packaged in SMD.

SMT is the abbreviation of Surface Mount Technology which is currently the most popular technology and process in the electronics assembly industry. SMT is a new generation of electronic assembly technology which compresses traditional electronic components into a device with a volume of only a few tenths, thus realizing high-density, high-reliability, miniaturization, low-cost, and automatic production of electronic products. This kind of miniaturized component is called: SMD device (or SMC, chip device). The process method of assembling components on the printed board PCB is called the SMT process.

At present, SMT technology is mainly realized through equipment which mainly includes loader machine, solder printer, automatic pick and machine, reflow oven, and various auxiliary tools and equipment.

If you want to know more about smt machine cost, please contact us.

在线联系供应商

Other supplier products

| SMT Equipment in Communication | The era of the Internet is inseparable from the popularization of communication equipment. SMD machine for mobile repairingemerge as the times requ... | |

| Tabletop SMT Pick And Place Machine | This kind of SMT pick and place machine features a dual head, 46 feeder slots, vision system, and flexible positioning system. The desktop smt pick... | |

| PICK AND PLACE MACHINE | The pcb smt pick and place machineis the equipment used to achieve high-speed and high-precision placement of components in the production line. Th... | |

| About Full-automatic Solder Printer PM400A | This automatic vision screen printer is the latest release of our printer. It features the latest machine vision recognition system, adopting highl... | |

| Solder Paste Mixer | The automatic SMT solder paste mixer machineuses the revolution to generate centrifugal force, and the force generated by the rotation at an angle ... |

Same products

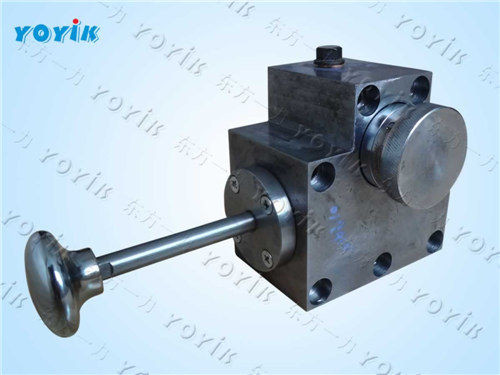

| plate throttle valve YSF16-55/130KKJ for Bokaro power (test) | 卖方: Dongfang Yoyik Engineering Co., Ltd | plate throttle valve YSF16-55/130KKJ In order to ensure the high quality of the products, YOYIK u... | |

| PUMP 100AY67X7 for Satpura power (test) | 卖方: Dongfang Yoyik Engineering Co., Ltd | PUMP 100AY67X7 YOYIK has been deeply involved in the field of power plant spare parts manufacturi... | |

| check valve F3RG06D330 for Kanti power (test) | 卖方: Dongfang Yoyik Engineering Co., Ltd | check valve F3RG06D330 Facing the changes in the energy industry, YOYIK keeps pace with the times... | |

| Rubber Bladder for ST High Pressure Accumulator NXQA-10/31.5 for Pacitan power (test) | 卖方: Dongfang Yoyik Engineering Co., Ltd | Rubber Bladder for ST High Pressure Accumulator NXQA-10/31.5 As a leading domestic supplier of po... | |

| vertical screw pump HSNH280-54A for Cirebon power | 卖方: Dongfang Yoyik Engineering Co., Ltd | vertical screw pump HSNH280-54A YOYIK, with advanced technical equipment and rich industry experi... |