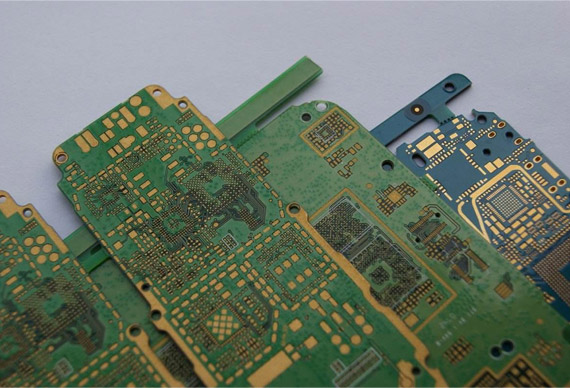

WIRING ON THE DOUBLE-SIDED BOARD——DOUBLE SIDED PCB

Speedapcb - The printed circuit board manufacturersin China, established in 2014, is located in Changsha, Hunan Province. The company focuses on high-speed PCB design, printed circuit board manufacturing, SMT welding processing, and supply chain services. Products are widely used in communications equipment, computers and network equipment, consumer electronics, automotive electronics, industrial control, new energy, rail transportation, and other industries.

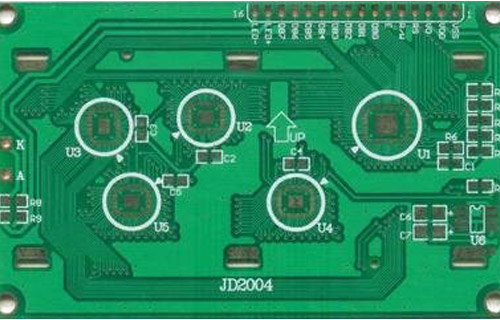

There are wiring on both sides of the dual layer PCB, but to use the wires on both sides, you must have a proper circuit connection between the two sides. This "bridge" between circuits is called a via. A via is a small hole filled or coated with metal on the two sided pcb. It can be connected to the wires on both sides. Because the area of the double-sided board is twice as large as the single-sided board, the dual layer PCB solves the difficulty of wiring interleaving in the single-sided board (which can be conducted to the other side through the hole), and it is more suitable for more complicated circuits than the single-sided board.

HAVE A QUESTION OR REQUEST?

Click below, we’ll be happy to assist.

SPEEDAPCB is a professional PCB supplier. We can provide customers with a one-stop service from PCB design to PCB production and assembly.

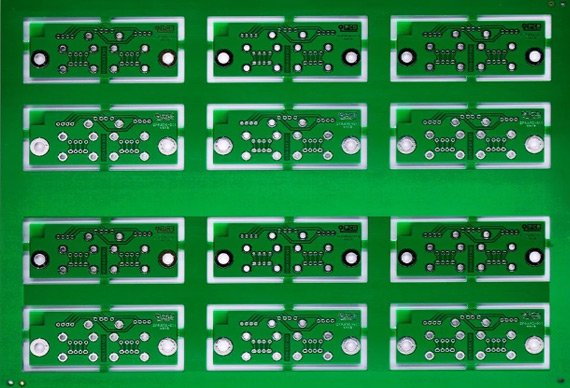

As a professional PCB manufacturer, we have 10 PCB production lines to manufacture double sided prototype pcb. The machine works 24 hours a day, only to provide customers with satisfactory delivery time.

Our PCB boards can be divided into single-panel double-panel and multilayer boards according to their structure. Thedouble sided circuit boardis a board with double-sided wiring on the board. An important feature of the double sided prototype PCB is that it has a guide hole to connect the wires on both sides into a circuit.And now the double sided pcb priceis reasonable.

The double-panel wiring can be staggered with each other, which is the biggest difference from a single-panel; the double-panel is more suitable for complex circuits and has a wider range of use.

The cost of single and double panels is not much different. If there is no special requirement, all industries will give preference to double panels; after all, the performance and stability of double panels are better than single panels.

Parameters of Double Sided PCB

|

Item |

Capabilities |

|

|

Number of Layers |

Double Side |

|

|

Material |

FR-4,CEM-3,HighTg, Aluminum, |

|

|

Halogen Free |

||

|

PCB Thickness |

||

|

Surface finished |

Gold Plating |

|

|

Immersion Gold(Silver) |

||

|

HAL Lead Free |

||

|

Hot Air Solder Leveling(HASL) |

||

|

Entek Coating (OSP) |

||

|

Solder Mask |

Any color Green, White,Black, Yellow, Red, Blue |

|

|

Other printing |

Gold Finger |

|

|

Carbon Print, Peelable Mask |

||

|

Solder Mask Plugged Hole |

||

|

Copper thickness |

1/ 2 oz (18 um) - 4 oz (140 um) |

|

|

Hole Size Tolerance (PTH) |

+/ -0.076mm (3 mil) |

|

|

Hole Size Tolerance (NPTH) |

+/-0.05mm (2 mil) |

|

|

Profile and V-Cut |

CNC-Routing, Stamping and Beveling, V-CUT,CNC |

|

|

Special Process |

Micro-section, Chamfer for Gold Finger |

|

|

Testing |

Electrical Testing, Controlled Impedance Testing, Flying Probe Test, X-Ray Inspection AOI Test |

|

|

Environment |

Clean room environmen , Dust-free workshop |

|

|

Transportation |

Fedex, DHL, UPS, etc. |

|

|

Files |

Gerber ,Protel ,Autocad ,Powerpcb, Orcad, etc. |

|

Description of Dual Layer PCB

Dual layer PCB, also called double sided board, it has wiring on both sides, but in order to use the wires on both sides. There must be a proper circuit connection between the two sides. This circuit between the "bridge" is called a guide hole (via). Guide holes are in the PCB, filled or coated with metal holes, which can be connected to the two sides of the wire. Because the double-sided panel is twice as large as the single-sided panel, the double-sided panel solves the difficulty of interlacing the wiring in the single-sided panel (you can pass through the hole to the other side), it is more suitable for use in more complex circuits than the single-sided panel.

Principle of Double Sided PCB Design

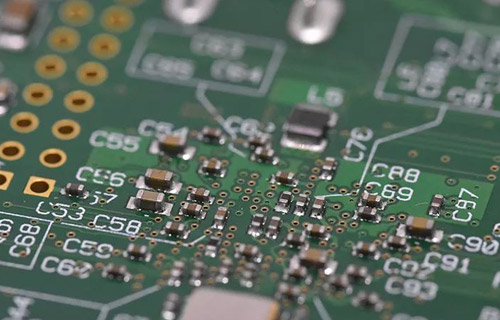

To get the best performance of electronic circuits, the layout of components and the layout of the wire is very important. In order to design a good quality and low cost PCB, the following general principles are suitable for single sided PCB design and double sided PCB design.

First, consider the size of the PCB size. PCB size is too large, the printed lines are long, the impedance increases, noise resistance decreases, and the cost increases; too small, it is not good heat dissipation, and the neighboring lines are vulnerable to interference. After determining the size of the PCB, then determine the location of special components. Finally, according to the functional unit of the circuit, the layout of all components of the circuit.

The wiring principles are as follows.

Solder pads

The center hole of the pad should be slightly larger than the device lead diameter. The pad is too large to form a false solder. Solder pad outer diameter D is generally not less than d + 1.2 mm, where d is the lead aperture diameter. For high-density digital circuits, the minimum diameter of the pad can be d + 1.0 mm.

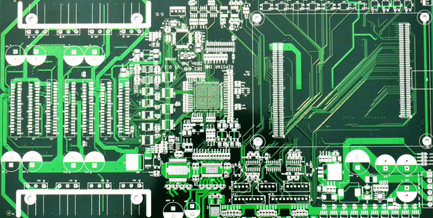

Function of Double Sided Printed Circuit Board

Double sided printed circuit board has the following functions in electronic equipment:

(1) To provide mechanical support for fixing and assembling various electronic components such as integrated circuits, to realize the wiring and electrical connection or electrical insulation between various electronic components such as integrated circuits, and to provide the required electrical characteristics.

(2) To provide solder resist graphics for automatic soldering and to provide identification characters and graphics for component insertion, inspection, and maintenance.

(3) electronic equipment using printed circuit boards, due to the consistency of similar printed circuit boards, to avoid errors in manual wiring, and can achieve automatic insertion or placement of electronic components, automatic soldering, automatic detection, to ensure the quality of electronic products, improve labor productivity, reduce costs, and facilitate maintenance.

(4) Provide the required electrical characteristics, characteristic impedance and electromagnetic compatibility characteristics for circuits in high-speed or high-frequency circuits.

(5) Printed boards with internally embedded passive components provide certain electrical functions, simplify electronic installation procedures, and improve product reliability.

(6)In large-scale and ultra-large-scale electronic packaging components, it provides an effective chip carrier for miniaturized chip packaging of electronic components.

在线联系供应商

Other supplier products

| High Speed PCB | Advantages of high-speed PCB: Multilayer PCB is generally used in high-speed PCB design. Multilayer circuit boards are actually formed by laminati... | |

| High-frequency PCB | High-frequency PCB is advancing to the trend of high speed, low consumption, small volume, and high anti-interference ability, which demands many n... | |

| OSP PCB - PRINTED CIRCUIT BOARD | OSP differs from other surface treatment processes in that it functions as a barrier layer between copper and air; in short, OSP is a chemically gr... | |

| LEAD FREE HASL PCB / IMMERSION TIN PCB | LEAD FREE HASL PCB / immersion tin pcb Lead-free HASL is to coat a layer of tin-lead alloy on the copper surface to prevent the oxidation of the co... | |

| HDI PCB / BLIND&BURIED VIA HOLE PCB / BVH PCB | SPEEDAPCB has been focusing on the production of various PTH (plated through hole PCB), buried via hole PCB and blind via hole PCB, and HDI PCB pro... |

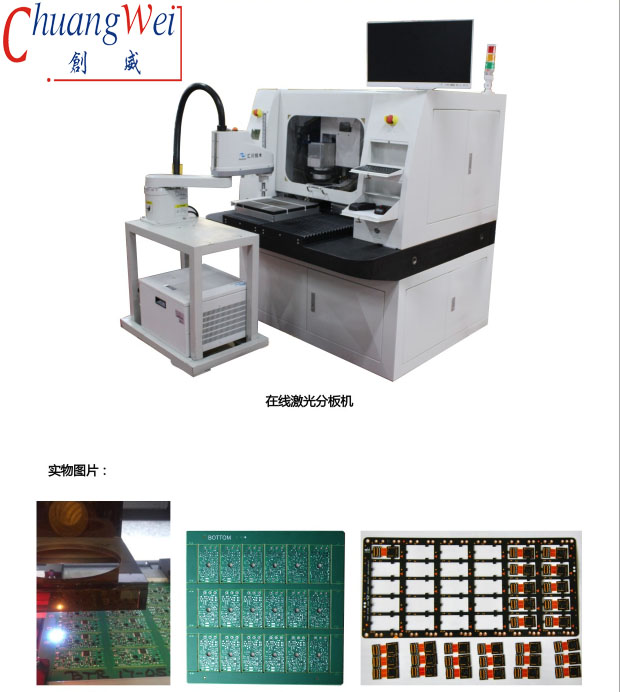

Same products

| 用于 FR4 / FPC 355nm 激光波长的大面积 PCB 分板机 | 卖方: 东莞市创威智能装备有限公司 | 这款激光分板机是一款功能强大且先进的 pcb 分板机、pcb 板切割机和 pcb 切割机。它旨在提供 FR4/FPC 材料的高深度切割、软件控制作和分板。该机器配备 10W/12W/15W/18... | |

| Lanrui G4 防爆分板工具 PCB 分离 | 卖方: 深圳维客修科技有限公司 | 产品描述 Lanrui G4 防爆拆板笔,强磁吸力,适用于分离 iPhone 手机主板,且不损坏手机。Lanrui 手机主板拆板笔配备可旋转强磁吸盘,可辅助拆卸各种双层主板,有效解决传统拆板方式... | |

| Professional PCB assembly manufacture for single side beauty mask PCB factory price PCBA service | 卖方: Shenzhen STHL Electronics Co.,Ltd. | SERVICES:electronic material procurement, PCB production, PCBA assembly, cable assembly, finished... | |

| High quality PCBA service PCB Control Board for led driver and projector e-kit with Tin Plating Prototype PCBA service | 卖方: Shenzhen STHL Electronics Co.,Ltd. | SERVICES:electronic material procurement, PCB production, PCBA assembly, cable assembly, finished... | |

| TSH-800 Crawler Mounted Water Well Drilling Rig | 卖方: Jinzhou City TongShun Drilling Machine Co.,Ltd | Versatile Drilling Capability: Drilling diameter range 140-400mm. Enhanced Efficiency: Drilling ... |