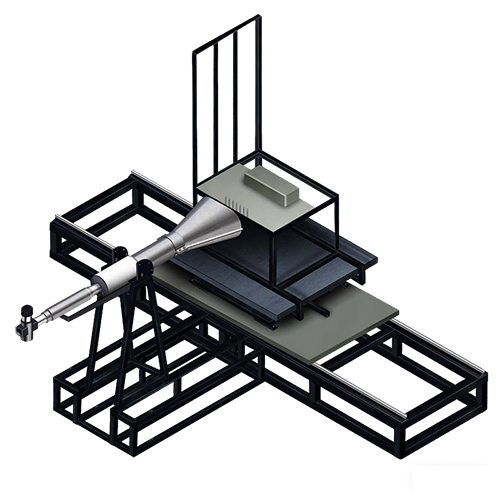

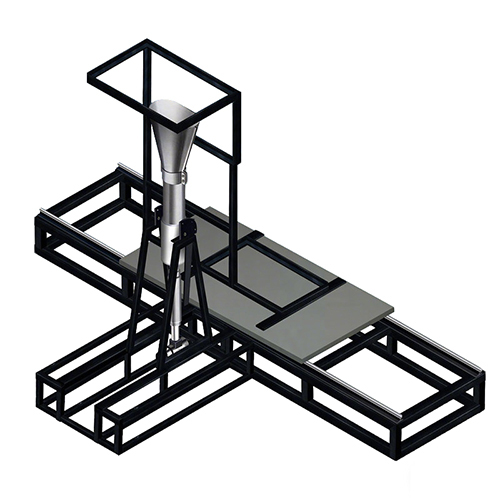

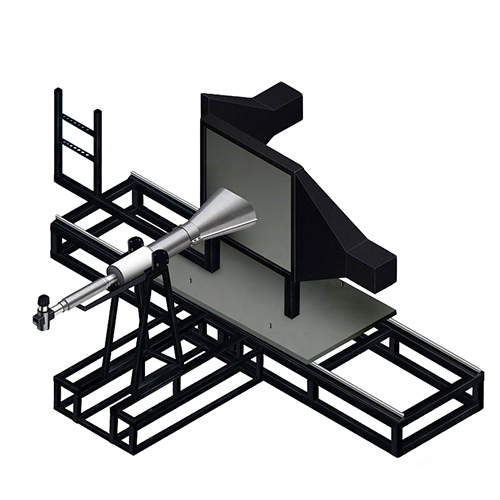

Metal Injection Molding (MIM) Debinding Sintering Furnace

Description

MIM debinding sintering furnace is mainly used for debinding sintering process of stainless steel, ferrous, titanium, alloy steel and high speed steel metal injection molding parts.

Technical Features

1. The MIM debinding and sinter furnace uses special hot zone structure and heating element design, assuring good temperature uniformity.

2. Special designed debinding muffle is adopted with good sealing and complete bind removable, preventing inside components pollution.

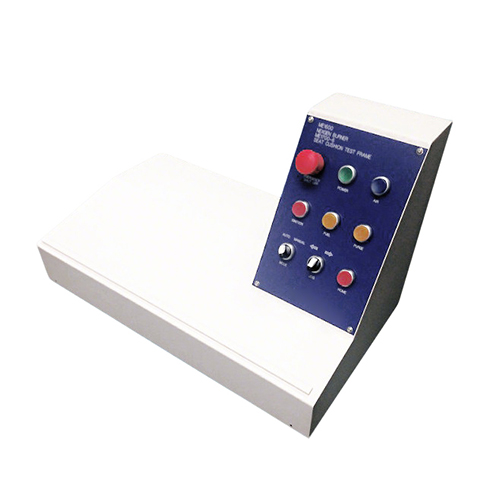

3. The touch screen operation and PLC central control are used to make the operation simple and reliable.

4. MIM debinding sintering furnace has functions of slow vacuum, minor positive pressure sinter, partial pressure sinter, minor negative pressure debinding and minor positive pressure debinding.

5. The furnace adopts advanced refractory structure and materials, which features good insulation performance and less heat absorption. It can save more than 20% energy compare o previous design.

6. The furnace has the functions of over temperature and over pressure fault alarm, mechanical automatic pressure protection and interlocking, which forms a highly safe furnace.

7. It has remote control operation, remote malfunction diagnosis and remote program update functions.

在线联系供应商

Other supplier products

| 气压烧结炉 | 该气压烧结炉主要用于碳化硅、氮化硅等陶瓷制品的真空烧结和压力烧结。 | |

| 真空氢气炉 | 该真空氢气炉主要用于工具钢、模具钢、高速钢、超高强度钢、磁性材料、不锈钢、有色金属、蓝宝石等材料在氢气气氛状态下的热处理。 | |

| 卧式双室真空高压气淬炉 | 该卧式双室真空高压气淬炉主要用于工具钢、模具钢、高速钢、超高强度钢等材料的真空气体淬火,加热室与淬火室分开结构,节能特点明显,冷却效果好。 | |

| 真空压力扩散焊炉 | 顶立真空炉VDP标准型钎焊及扩散焊炉主要用于航空、航天、船舶等各类发动机叶片、隼头、导弹引信等部件的扩散焊接工艺,扩散焊焊接应用广泛,可以完成不同种类金属材料与金属材料之间的扩散焊接、也可以完成不同种类金属材料与陶瓷类材料、非金属类材料之间的扩散焊接。 | |

| 网带式烧结炉 | 该网带式烧结炉主要用于粉末冶金铁铜基零件的高温烧结,如含油轴承、齿轮、离合器片、轴瓦和衬套等零件的烧结处理。 |