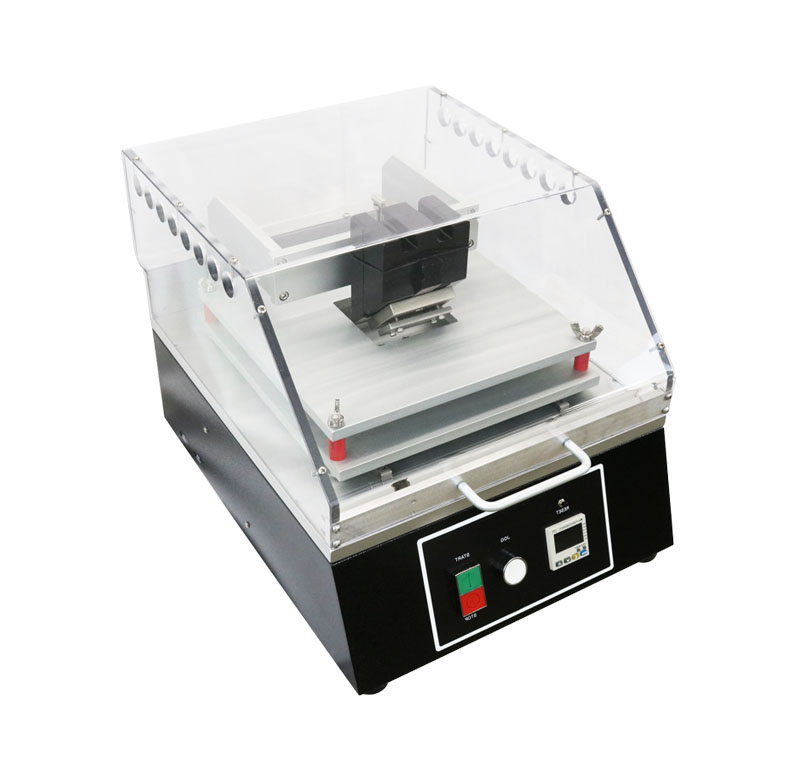

Next Generation Impactor(NGI)

The next generation impactorTM, or NGITM, is a high performance cascade impactor for classifying aerosol particle into size fractions for testing meter-dose and dry-power inhaler and other inhaled drug delivery devices such as nebulizers and nasal sprays. MSP developed the NGI in conjunction with a consortium of 15 pharmaceutical companies, resulting in superior aerodynamic performance, low inter-stage losses, and user-friendly features, The NGI is recognized internationally both in the USP and the EP. It features removable collection cups, O-ring-free connections, and a micro-orifice collector that can be used in place of a final filter for most formulation. These features make the NGI an easy-to-use, efficient workstation, enabling 10 to 20 inhaler determinations per day with one impactor, resulting in less capital equipment and a cleaner, more efficient laboratory.

Designed specifically for the pharmaceutical industry for testing metered-dose inhalers (MDI), dry-power inhalers (DPI), nebulizer and nasal sprays.

Provides high-accuracy data and unappalled productivity.

Features

1.Seven impaction stages plus a final micro-orifice collector that can be used in place of a final filter for most formulations.

2.Known stage cut size from 15L/min to 100L/min with no change of parts needed for entre range.

3.Also calibrated at 15L/min specifically for nebulizers.

4.Seven stages with at least five with D50values between 0.54 and 6.12 μm at all design flow rates.

5.Removable set of collection cups, hinged removable lid, and O-ring free inlet connections.

6.Electrically conductive and corrosion resistant.

7.316 stainless steel USP induction port.

8.One pre-separator for entire range of 30L/min to 100L/min W/O changing parts.

Technical Parameters

| Items |

Parameters |

| Flow rate |

15-100L/min |

| Stage cut point(1-7 stages) |

Look up the USP 601 Section, Table 6 for more information |

| D50@30L/min |

11.4, 6.4, 4.0, 2.3, 1.4, 0.80, 0.54 µm |

| D50@ 60 L/min |

8.1, 4.4, 2.8, 1.7, 0.94, 0.55, 0.34 µm |

| D50@100 L/min |

6.1, 3.4, 2.2, 1.3, 0.72, 0.40, 0.24 µm |

| Weight |

9kg |

| Dimension |

600 x 330 x 130 mm (L x W x H) |

Other supplier products

|

|

Xenon Arc Weatherometer - Test Equipment |

The xenon arc lamp, which is capable of simulating the whole natural sunlight spectrum in the most consistent manner, can reproduce the destructive... |

|

|

Sealing Strip Wear Test Machine - lab instrument |

We are a professional testing instrument manufacturer offering complete laboratory testing solutions. If you need more information or wish to explo... |

|

|

Air Permeability Tester |

Applications

The Air Permeability Tester accurately and swiftly determines the resistance of fabrics (woven, knitted and nonwoven textile) to the ... |

|

|

Blackboard Shaker |

The Blackboard Shaker is a precision instrument designed for evaluating the appearance quality of yarns. It shakes yarns of specified density acros... |

|

|

Gakushin Type Rubbing Tester |

ThisGakushin Type Rubbing Testeris a standard testing machine of the Type II rubbing tester (GAKUSIN TYPE) specified in JIS L0849Test Method of Rub... |

供应产品

Same products