Two-Stage Screw Air Compressor

By employing two-stage compression, an intermediate cooler can be introduced between the stages. This allows the compressed gas, after the initial compression stage, to undergo isobaric cooling, reducing its temperature before entering the subsequent cylinder. Lower temperature and increased density facilitate further compression, resulting in significant power savings compared to single-stage compression. Consequently, the work area under two-stage compression at the same pressure is smaller than that of single-stage compression.

Principle of Two-Stage Screw Air Compressor

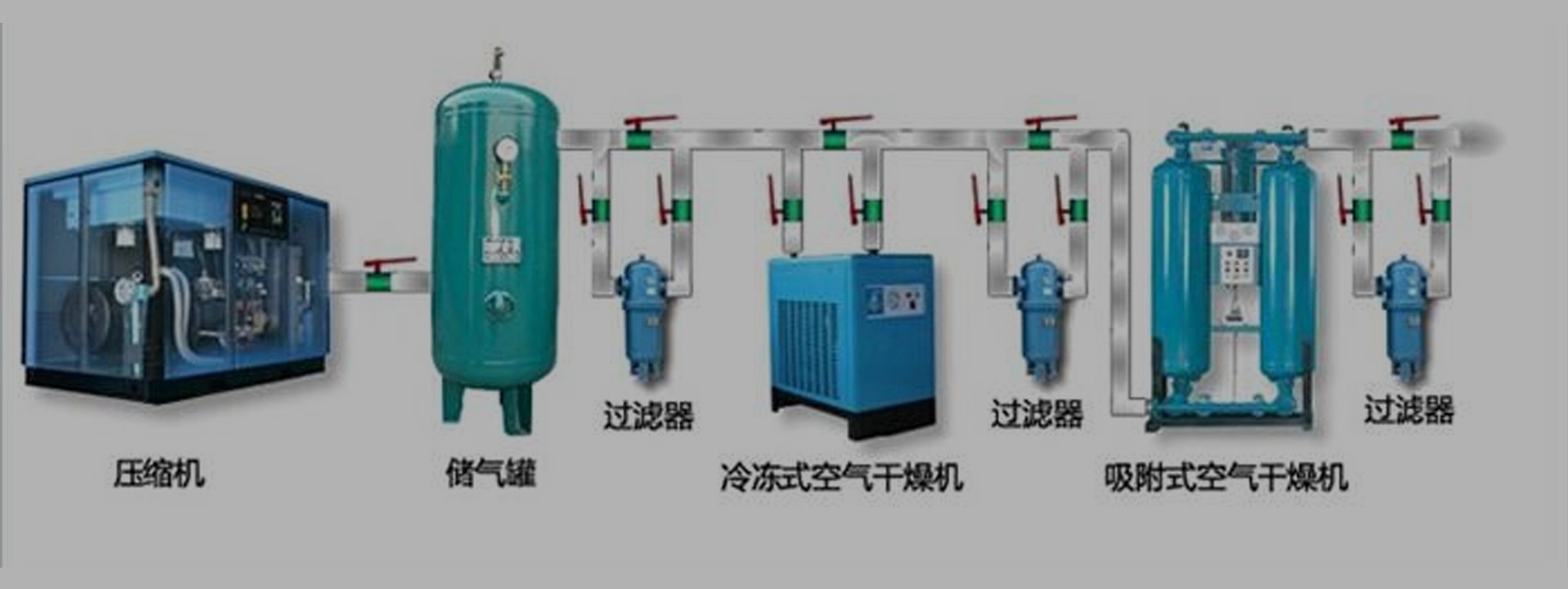

The principle of the wholesale two stage screw air compressorinvolves a natural air intake through an air filter into the first compression stage. In this stage, the incoming air mixes with a small amount of lubricating oil and is compressed to an intermediate pressure. The compressed gas then enters a cooling channel where it comes into contact with a significant amount of oil mist, effectively reducing its temperature. After cooling, the compressed gas enters the second rotor for the second compression stage, resulting in the gas being compressed to the final discharge pressure. Finally, the compressed gas is discharged through an exhaust flange, completing the entire compression process. While various designs exist, the fundamental principles are similar.

How to Differentiate Between Single-Stage, Two-Stage, and Multi-Stage Compressors

Distinguishing Between Single-Stage and 2 stage screw compressorBased on Machine Structure.

A single-stage air compressor consists of a pair of rotors that make up a rotary screw compressor, achieving air compression in a single step.

A two stage screw compressorconsists of two pairs of rotors. After the gas undergoes the first stage of compression, it enters the second stage for further compression. The compression ratio is higher, and the power is reduced compared to a single-stage compressor.

By splitting the compression process into two stages and setting inter-stage pressure using equal pressure ratios, the compression ratio for each stage is significantly lower than that of a single-stage compressor. This results in a substantial reduction in rotor backflow leakage, leading to improved volumetric and adiabatic efficiencies, consequently increasing the final gas output.

There are many rotary air compressor manufacturers, but we are one of the best choices for you.

在线联系供应商

Other supplier products

| Portable Screw Air Compressor | AULISS Portable Screw Air Compressoris one of the most advanced models both domestically and internationally, making it an ideal choice for users i... | |

| Micro-Oil Screw Air Compressor | The micro-oil screw compressor has the characteristics of reliable operation, few wearing parts, low vibration, low noise, and high efficiency. The... | |

| AULISS Rotary Screw Air Compressor | Industrial Rotary Screw Air Compressor is a machine designed based on the screw air compressor working principle of volume changes caused by the ro... | |

| Medium-Pressure Screw Air Compressor | The AULISS medium pressure air compressorsemploys a German linear screw main unit, capable of reaching a maximum pressure of 30 bar. The main unit ... | |

| Screw Vacuum Pump | A rotary screw vacuum pumpsis a device that generates, improves and maintains vacuum in a closed space by various methods. A china screw vacuum pum... |

Same products

| Filton Filter Air Filter LW-1242 | 卖方: Filton Tech (Shanghai) Co., Ltd | Filton Filter Air Filter LW-1242 Filton LW-1242Air Filter for X3 (F25) xDrive 28 i Black PP rou... | |

| Two-Stage Screw Air Compressor | 卖方: Auliss Henan Intelligent Technology Co., ltd. | By employing two-stage compression, an intermediate cooler can be introduced between the stages. ... | |

| Silicone Ice Cream Cake Molds | 卖方: Yangjiang Bohao ENTERPRISE CO., LTD | There are 6pcs of the silicone cake ice cream mould, enough quantity to meet your various needs. ... | |

| Clean Room Hepa Fan Filter Unit FFU | 卖方: Snyli Environmental Technology (Shandong) Co., Ltd. | Clean room HEPA fan filter unit (HEPA FFU) are mostly used in Class 10 and Class 100 clean rooms.... | |

| High Temperature Resistance HEPA Filter | 卖方: Snyli Environmental Technology (Shandong) Co., Ltd. | Product Overview High Temperature Resistance HEPA Filter is especially designed to remove airbor... |