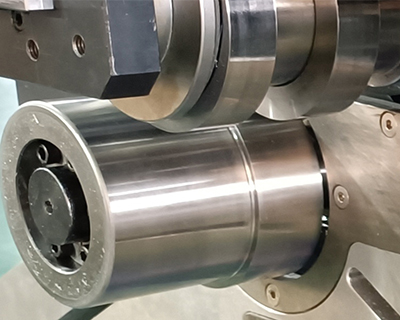

AUTOMOBILE BRAKE PAD STEEL BACK SPOT WELDING MACHINE

The automobile brake pad steel back spot welding machine adopts the intermediate frequency controller, which has high control precision, stable output current and saves power compared with the power frequency. The equipment has the function of single/continuous spot welding, and can perform welding of various specifications in a continuous cycle. The welding points of the same workpiece at different positions use different welding processes, which saves the tedious work of manpower switching welding specifications.

THE PARAMETER OF AUTOMOBILE BRAKE PAD STEEL BACK SPOT WELDING MACHINE

|

Enter capacity |

Input voltage |

Output current |

Rated frequency |

Load sustained rate |

Max pressure |

Max welding size |

Cooling water |

Cooling water temperature |

Input cable |

|

250KVA |

3*380V |

32KA |

50/60Hz |

50% |

7800N |

230*180mm |

20L/min |

5~15℃ |

75㎡ |

The Application Of Automobile Brake Pad Steel Back Spot Welding Machine

The equipment is mainly used for spot welding of steel backs of automobile brake pads, and is a special machine for spot welding of steel backs of brake pads. The welding machine adopts an intermediate frequency controller, which has high control precision and stable output current, which saves power compared with power frequency. The equipment has the function of single/continuous spot welding, and performs various specifications of welding in a continuous cycle. The pre-pressing time and welding current of each solder joint on the welded product can be adjusted individually to minimize the scrap rate.

The Advantages Of Automobile Brake Pad Steel Back Spot Welding Machine

The equipment has the counting function to count the welding times, which is convenient to understand the production on duty, greatly improving the work efficiency and reducing the shift change time. Three phase power input, three-phase stability, small impact on the power grid, small transformer loss, and significant energy-saving effect. The three discharge pulses can be set separately and used separately or in any combination. High flexible multi-layer copper tape is used for conduction, which has the advantages of high conductivity, good heat dissipation conditions, convenient maintenance, etc.

Other Notes Of Automobile Brake Pad Steel Back Spot Welding Machine

Automobile brake pad steel back spot welding machine Main Characteristics

1

Adopt intermediate frequency controller, high welding control precision.

2

The output current is stable, achieving the effect of energy saving.

3

The equipment has the function of single and continuous spot welding, eliminating the need for manual switching of welding work.

4

High-flexibility multi-layer copper tape is used for electrical conduction, with high electrical conductivity.

5

The scrap rate is low. When the current is abnormal, the equipment will automatically alarm and stop.

6

The hydraulic angle cylinder is adopted, which improves the clamping force and the welding quality and appearance of the product.

We can offer sorts of light weld 1500 laser welding systemfor sale, if you are interested, please contact us.

As one of laser welding machine suppliers, we can offer sorts of laser welding machine chinafor sale, anything you need, please leave us a message.

在线联系供应商

Other supplier products

| PAPER DRUM STAINLESS STEEL BELT CRIMPING MACHINE | This equipment is designed for crimping and forming after welding of paper drum stainless steel rings. It is connected with our automatic laser wel... | |

| DUST COVER WELDING MACHINE | DUST COVER WELDING MACHINE The Dust Cover Welding Machine is a machine designed to make covers for welding machines. The machine uses a welding pr... | |

| SANDER POLISHER MACHINE | Sander and polisher machineis designed to eliminate the need for hand sanding. It is a simple yet effective machine that enables you to quickly rem... | |

| DOUBLE ENDED POLISHING MACHINE | Double ended polishing machineusing Inovance PLC (programmable logic controller) control system;The polishing wheel is made of hemp wheel material,... | |

| AUTOMATION EQUIPMENT FOR AUTO PARTS INDUSTRY | For the auto parts industry, we have independently developed welding equipment such as brake shoe seam welding machine, fillet welding machine, plu... |

Same products

| MECHANIC 10cc 焊膏助焊剂,适用于手机 SMT PCB 焊接 | 卖方: Phonefix | MECHANIC 注射器式焊膏 (Sn63/Pb37),适用于手机 BGA 和 SMT 维修。这款 10cc 锡膏包含一个注射器和三根针头,方便在元件焊接过程中精确涂抹于 PCB 焊盘上。 产... | |

| YCS M.Y 140/160/183/199°C Solder Paste for Phone PCB IC Repair | 卖方: China PHONEFIX Technology Co., Ltd | YCS M.Y-XJ01 140℃/160℃/183℃/199℃ 高温焊膏,适用于手机PCB、CPU、IC及电子元件球形贴片的维修。YCS M.Y焊膏采用先进配方技术,提供卓越的焊接效果。杨师傅... | |

| MECHANIC T210 SE 数字显示焊台适用于精密 PCB 维修 | 卖方: Phonefix | MECHANIC T210 SE 50W 数字显示恒温焊台,支持 C210 系列烙铁头,具备三档温度存储和智能自动休眠功能,5 秒快速加热,6 秒即可熔化锡,适用于手机主板维修、电子产品电路板维... | |

| SUNSHINE SS-6604 SS-6605 Soldering Smoke Purifier Fume Extractor | 卖方: China PHONEFIX Technology Co., Ltd | 产品描述 SUNSHINE SS-6604 SS-66045 烟雾净化器,适用于手机维修、焊接、激光雕刻等行业。这款强大的烟雾净化器可有效去除铅烟、松香、烟雾和异味等有害物质。它可与激光机和焊台... | |

| MECHANIC M35 手机主板维修助焊膏 | 卖方: Phonefix | Mechanic M35 10CC 纳米助焊膏活性高达 98%。高效协同配方,为手机主板、BGA 芯片焊接及常规助焊提供卓越的焊接性能。 产品特点: 1. 纯净配方,无杂质,内外通透细腻。 2... |