Overflow Ball Mill

n recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, overflow type ball millis the most widely used equipment in wet grinding. Overflow ball millis mainly used for wet ballmill. In the grinding process, raw materials and water are added at the same time to make the ground fine materials form pulp with water, which is discharged in the way of self flow, so as to complete the industrial grinding mill operation, so it is called an overflow mill.

Features of Overflow Mill

Overflow mill is easy to start, stable operation

Simple structure, convenient maintenance

Various working modes and optional granularity

The grinding time is short and the service life is long

Application of Overflow Ball Mill

Overflow ball mill is often used for grinding fine ore or regrinding concentrate in mineral processing industry, such as cement ball mill. In addition, it can also be used in silicate products, building materials, chemical fertilizers, non-ferrous metals, glass ceramics and other production industries.

Working Principle of Overflow Ball Mill

When overflow mill is working, raw materials and water are continuously added from one port, and the slurry is formed after being ground by steel ball inside the cylinder. After the slurry is ground to the target size and accumulated to a certain height, it will overflow from the other end.

Advantages of Overflow Ball Mill

Rich Experience: We have produced hundreds of overflow ball mills every year. We ensure the quality and provide after-sales service. The ball mill grinding machine has a long service life.

Strong Production Capacity: We can make quick delivery with our 6 factories and 800+ workers.

Reasonable price: We have long-term cooperation with hundreds of suppliers, and will lower the cost of raw materials and processing.

Intelligent Grinding Expert System-Ball Mill

To realize the intelligent control for ball mill operation, we provide the intelligent grinding expert system. It will monitor the situation of ball mill working and the finished products status. Lower the labour cost with great efficient. Learn More...

在线联系供应商

Other supplier products

| Vertical Centrifuge | The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm , the rotor body (including the blade), transmiss... | |

| Sludge Dryer Machine | CIC's sludge drying machine process was originally developed for the development of high viscosity media in the concentrating chemical industry and... | |

| SAG Mill | Semi autogenous millor SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and screen... | |

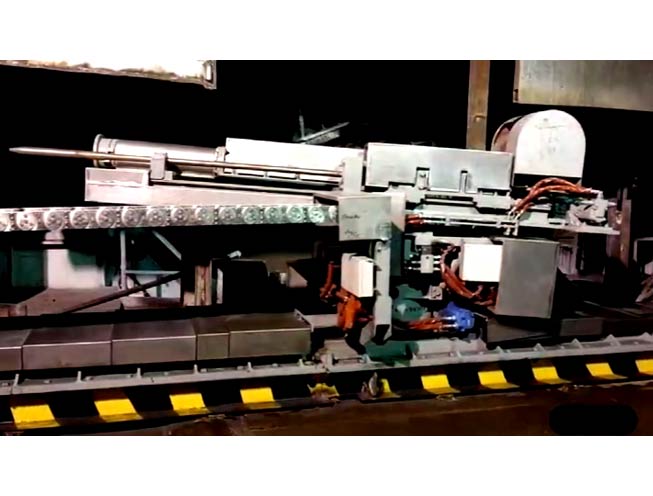

| Automatic Drilling and Tapping Machine | Automatic Drilling and Tapping Machine The manipulator is applied to the opening and plugging of the slag port in a copper smelting furnace. Acc... | |

| Overflow Ball Mill | n recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, overflow type ball millis t... |

Same products

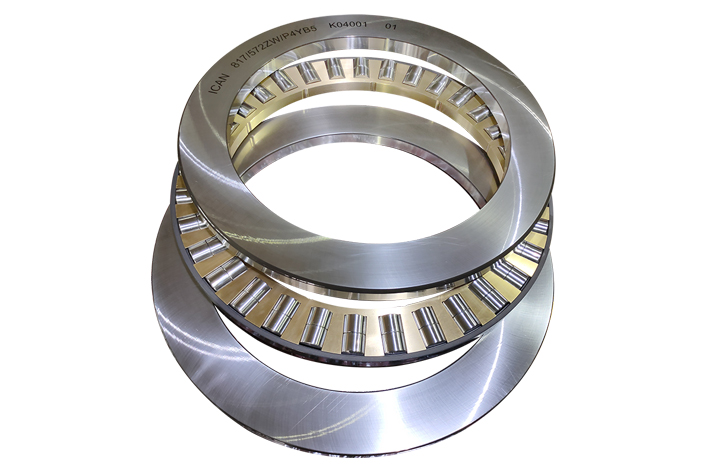

| Cylindrical Roller Thrust Bearing | 卖方: DLAIAN GUANGYANG BEARING CO., LTD | Cylindrical Roller Thrust Bearing Cylindrical roller thrust bearings consist of rollers, cage co... | |

| Overflow Ball Mill | 卖方: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | n recent years, with the continuous development of grinding technology, wet grinding has become t... | |

| Metallurgical Furnace | 卖方: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | CIC main advantage in nonferrous metallurgical furnacelies in the manufacture of horizontal rotar... | |

| NTN 51236 Bearing,180x250x56,INA 51236 | 卖方: BEARING POWER International Trading Co.,Ltd. | NTN 51236,Thrust Ball Bearing,180x250x56,INA 51236 | |

| INA 52305 Bearing,25x52x34,NTN 52305 | 卖方: OKB INDUSTRIAL CO.,LTD. | INA 52305,Thrust Ball Bearing,25x52x34,NTN 52305 |