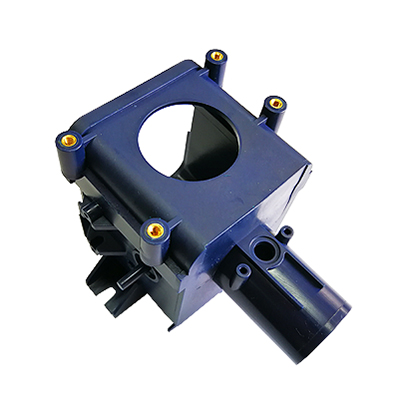

Electronic Molding Parts

HanKing Mould Enginering Ltd. started the business in the year of 1996 as one of the chinese plastic injection molding companiesin the line of mold making and injection molding in Longgang, Shenzhen, China. With continuous developments and progresses, we have become a professional Chinese plastic injection tooling company, offering custom plastic injection molding service, plastic molding manufacturing and other mould making services.

As one of the electronic spare parts manufacturers, we are specialized in manufacturing of high quality products.

Two Color Tooth Brush Injection Mould Plastic Parts

Make plastic injection mold and injection mouldingproduction for two color tooth brush injection mould plastic parts, plastic handle.

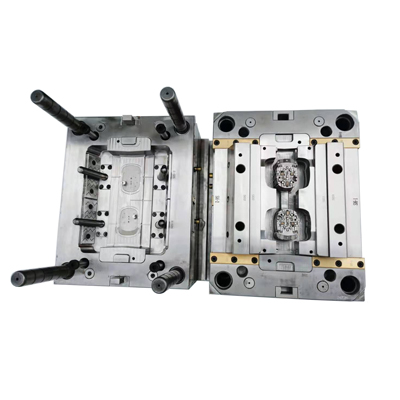

Plastic Injection Mold for Usb Charger

Place of Origin: Guangdong, ChinaShaping Mode: Plastic Injection MouldProduct Material: Steel MouldProduct: Electronic USB charger adapterMould export to: EuropeCavity number: 1*2 cavities, 1*4 caviti...

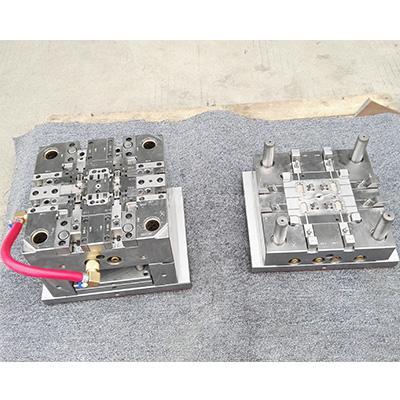

Plastic Injection Mould Structure

The structure of the plastic injection mold is related tomany factors such as the variety of plastics, the shapeof the product, the dimensional accuracy, the productionbatch, the injection process...

Custom Injection Molding

Custom injection mold making and molding for electricalplastic parts & components.Since the company start export business in year 2011we have worked on hundreds of projects for customersfrom...

Plastic Injection Moulding Die Makers

Plastic injection mould & die maker in China.Focus on all kinds of mould development, various plasticmold manufacturing, mould design, injection molding, silkscreen, tampon printing, assembly...

China Mold Maker

HanKing provide one-stop production of electrical productsfrom prototype – plastic mold making - mass production.Professional, rapid prototyping design, dedicated to castingquality plastic products. ...

What are electrical molding parts?

This is classified according to the purpose of the finished terminal product, involving electronic plastic parts and electrical plastic accessories.

In modern society, more and more products use electronic components. Medical equipment, home appliances, and automotive products, etc. all use electrical parts.

How to make good quality electronic parts?

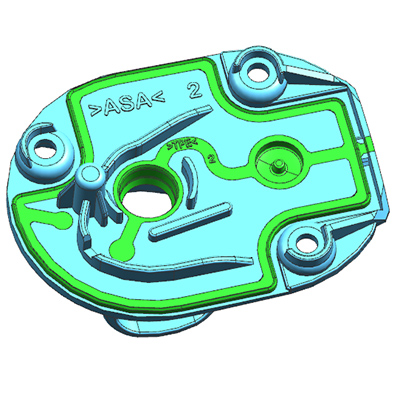

The first is good part design, second is good mold design, precision equipment and skilled technician is also very critical.

The structure of the product should be reasonable and can be completely released from the mold, so our customers will discuss with us before making the mold. We welcome customers to send an inquiry, and it is very happy to work together to create high-quality products. Normally, we will give suggestions related to parting line, gate location & type, ejection location, surface finishing, angle draft analyze, wall thickness analyze and send part design optimization proposal to the customer.

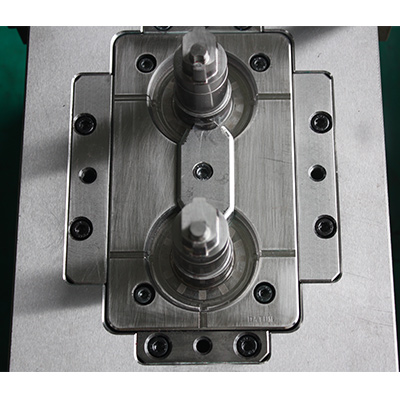

What facility is needed to make an electrical molding part?

We use the milling machines, CNC machines, grinding machines, EDM, wire cutting machines to make injection mould, and make injection mold trials with Haitian injection machines.

In generally there are internal plastic parts and external plastic parts, dimension is very important for internal functional parts, most of the time, as long as the steel size of the mold is within tolerance, the dimension of the part that is injection molded will not NG.

And the external parts are visible, and must have a good appearance. In addition to the corresponding processing of the mold surface, the injection molding machine setting is also very important, usually, need to try a large number of parameter combinations when making mold trial.

在线联系供应商

Other supplier products

| 2k Injection Mold | 2k mouldspecification Part function: Water plastic manifold Part material: PP & TPE Shrinkage: 1.6% Cavity: 1 cavity Mould base: 1.1730 A... | |

| Precision Mould | How to build a plastic precision mould? We have been manufacturing plastic precision moulds and componentsfor more than ten years. With our expe... | |

| Over-Molding Parts | Custom Mold & Design The overmolded partsis a process that can bond different materials by the injection moulding. Plastic injection ove... | |

| Industrial Molding Parts | Injection molded parts Part size: 124*152*80mmPart material: ASACavity: 2 cavitiesMould weight: 875kg Mold size: 600*610*880mmMould type: plastic i... | |

| Automotive Mold | HanKing Mould serves global Automotive & Vehicle products customers, more than 10 years of experience enabling the HanKing team to provide cust... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |