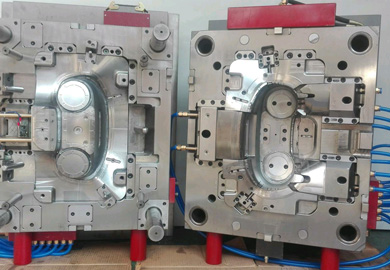

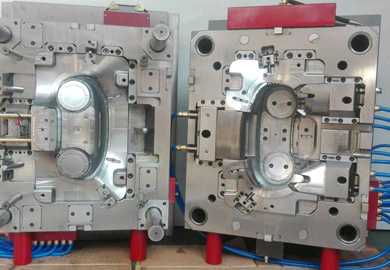

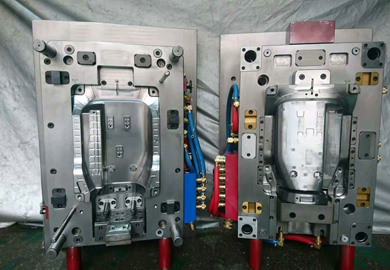

2K Mould

2k mouldingis a manufacturing process that refers to molding two materials or colors into one plastic part.

This technology combines two materials or two colors into one ending plastic part by using a 2K automotive plastic injection moulding machine. The selection of the 2K moulding process is generally according to cost and customization considerations.

Features of 2k mold

Physical appearance

The physical appearance of 2K injection molding about aesthetic value or beauty is high as many colors can be blended in the molding stages.

Cost-efficiency

Because all 2K molding manufacturing procedures are finished in the injection stage, it can save plastic injection molding cost and lower the labor and material fees.

Customization

As a china injection molding company, we can provide custom-made plastic injection molding products to meet your demanding need. It is possible to finish the products with 2K plastic injection moulding with softer edges.

The Specification of 2K Mould

|

Part material |

PC + ABS |

|

Cavity |

1L + 1R |

|

Mold accuracy |

+ / - 0.01 |

|

Mold steel |

|

|

Moldbase steel |

|

|

Mold life |

100W |

|

Mold standard |

HASCO |

|

Mold structure |

6 lifters |

|

Exporting country |

Germany |

|

Delivery time |

4 weeks |

|

Mold quality customer satisfaction |

98% |

|

FAI pass rate |

96% |

|

Project cooperation service customer satisfaction |

98% |

How does 2K Mould Work?

Since there are a lot of benefits of 2K injection molding, can I learn more about the working principle of 2K mould?

2K injection moulding operates in one machine which is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The 2K plastic injection moulding is then rotated automatically and another type of plastic is injected from a second nozzle into the mold. When using the 2k injection molding technology process, material selection is very important to the injection.

If you want to know more details of mold tech china, please visit our website.

在线联系供应商

Other supplier products

| Injection Moulding Products | GM-TECH has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. We are also experienced in th... | |

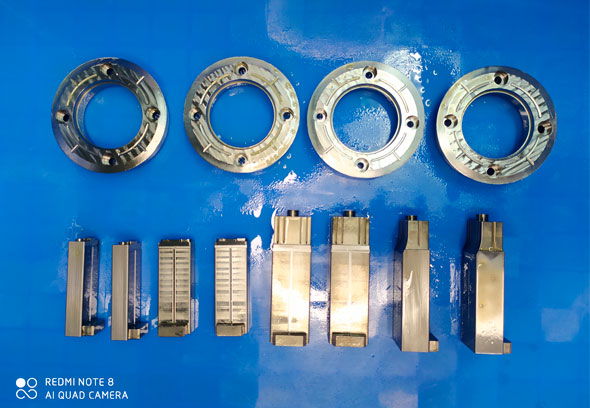

| Mould Slide | GM-TECH, a plastic injection manufacturer, has been manufacturing tools for injection molding of plastics for various industries for more than 10 y... | |

| Mould Spare Part | Mould Spare Parts Plastic mold accessories include single section shoot, double section shoot, double section shoot, flat tip, flat tip, positioni... | |

| 2K Mould | 2k mouldingis a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines two materia... | |

| Insert Mould | Insert molding is an injection molding process used to encapsulate a component in a plastic part. The insert custom plastic injection moldingpro... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |