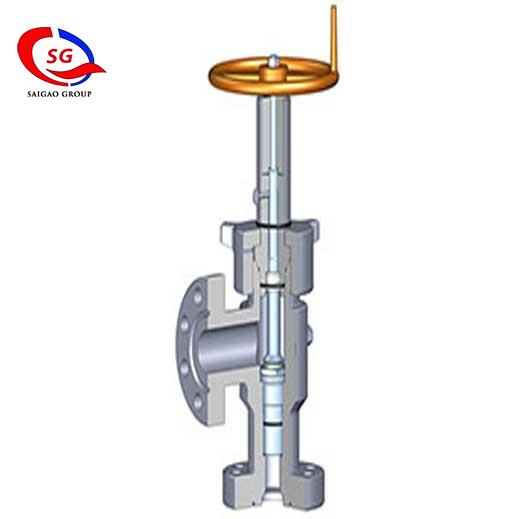

Hydraulic Liner Hanger Tie-Back Assembly

The tie-back assembly is a special cementing tool for tieback operation.

Tieback equipment allows existing liners with a receptacle to be extended to the surface or farther up hole, and provides a high-pressure seal at the top of a cemented or uncemented liner. TIW offers variety of tieback seal nipples and tieback packers to accommodate liner top extension and remedial operations.

Tieback Procedures of Hydraulic Liner Hanger Tie-Back Assembly

Measure and drift the casings carefully and clean all the threads.

Calculate the kelly-up of the casing (the particular part of the last casing which is above the rotary table) and arrange the casing string.

Prepare several casings, which are approximately 0.5m shorter than the others and convenient for kelly-up calibration. (The actual kelly-up is not equal to the calculated value due to measurement error and the remaining threads of the casings.)

Connect the milling shoe and trip in. Polish the inner surface of the polished bore receptacle, make sure there is no debris.

Note the depth of the milling shoe when it reaches the top of the seal assembly (judge from the changes on pressure and WOB). Then lift the drill string for 1m.

Use a drilling rate of 40~50rpm and a normal flow rate. Slowly lower the drill string. Polish the inner surface of the polished bore receptacle twice or three times. Each time polish 3~4min. During the last polishing, apply an additional load of 2~3t when the torque suddenly increases (the milling shoe reaches the top of the seal assembly) during the last polishing. Polish for another 2~3min and note the depth of the milling shoe, which is an important clue for the casing setting depth.

Circulate with high flow rate for 5min.

Trip out and check the milling shoe. If there is a circle of polished trace and the diameter is equal to the I.D. of the left thread on the seal assembly, then the milling shoe have reached the bottom of the polished bore receptacle.

Features ofHydraulic Liner Hanger Tie-Back Assembly

With the guide shoe and circulate bore, it can stab into polished bore receptacle before cementing, more convenient than conventional cementing which pumps down cement before stabbing.

With its streamline shape, the guide shoe can stab into polished bore receptacle easily.

The Tieback Seal Assembly with three stacks of molyglass seal is designed for high-pressure and high-temperature liner tieback completions. Available in seal length is 1.2m.

Technical Parameters ofHydraulic Liner Hanger Tie-Back Assembly

|

Specifications, mm |

Φ177.8 |

Φ127.0 |

|

Sealing capacity, MPa |

25 |

25 |

|

Heat-proof Rating, ℃ |

120 |

120 |

|

Available Sealing Length, mm |

1200 |

1200 |

|

Φ155 |

Φ108 |

SAIGAO GROUPis one of professional oil equipment suppliers. We provide Fishing Tools, Mud Pump Parts, tie back receptacle, tie back cementing, tie back casing, liner hanger assembly, hydraulic hanger, casing tie back, tie back linerand so on. Want to know about tie back liner procedure? Please contact us.

在线联系供应商

Other supplier products

| Hydraulic Liner Hanger Tie-Back Assembly | The tie-back assembly is a special cementing tool for tieback operation. Tieback equipment allows existing liners with a receptacle to be extend... | |

| Fishing Magnet | Fishing Magnet is a junk retrieval tool designed to retrieve small metal, odd-shaped objects such as mill metal shavings, bit cones, cutters, bear... | |

| Adjustable Choke Valve | Adjustable Choke Valvehas forged steel valve body, which is characterized as high pressure resistance and erosion resistance. It can be operated ma... | |

| Wellhead Equipments | A Few Words about Wellhead Equipment A wellhead is a component located on the surface of oil or gas well, which provides structure and pressure ... | |

| Hydraulic Liner Hanger Tie-Back Assembly | The tie-back assembly is a special cementing tool for tieback operation. Tieback equipment allows existing liners with a receptacle to be extended... |

Same products

| High Vacuum Pump 2be 203 Series Water Ring Pump | 卖方: Greentech International (Zhangqiu) Co., Ltd | Application scope and characteristics: Greentech International (Zhangqiu) Co., Ltd is the profes... | |

| Zbk03 Series Roots Vacuum Pump/Roots Pump | 卖方: Greentech International (Zhangqiu) Co., Ltd | ZBK series roots vacuum pump is a kind of coarse vacuum acquisition of equipment, it is widely us... | |

| "Brand Assurance Globe valve GR2-0-KB-G5/30X48 for power generation | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Brand Assurance Globe valve GR2-0-KB-G5/30X48 for power generation YOYIK is a large number of st... | |

| Wear Resistance Electric stop valve NKJ961Y-16C for thermal power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Wear Resistance Electric stop valve NKJ961Y-16C for thermal power plant YOYIK professional produ... | |

| Brand Assurance Stop valve J61Y-600CL for power generation | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Brand Assurance Stop valve J61Y-600CL for power generation YOYIK is a large number of steam turb... |